Table of Contents

Quick Overview

Here is the quick summary on air compressor maintenance:

- Air compressor maintenance is essential to ensure smooth operation and extend its lifespan.

- Changing oil can keep the air compressor parts lubricated.

- Maintain the industrial compressors to prevent costly downtime.

- Cleaning or replacing air filters ensuring efficient airflow.

- Drain condensate regular to avoid rust and moisture damage.

- Inspect and adjust belts for proper tension and wear.

- Check all the electrical connections for safety and reliability.

- Schedule professional servicing for thorough inspections and repairs.

Owning an air compressor can be very helpful for DIY projects at home or for larger jobs in an industrial setting. These machines save time and effort, enabling you to perform tasks such as inflating tires and powering tools efficiently. However, they require regular maintenance to function properly. Taking care of your air compressor will help it run smoothly and can extend its lifespan.

Maintaining air compressor may seem challenging task for you but breaking it down into simple steps makes it easier. Regular cleaning is crucial to keep your compressor reliable and reduce the risk of breakdowns.

Air Compressor Maintenance Tips

Here are some tips for air compressor maintenance to keep it in good condition.

1. Changing Oil Regularly

Many air compressors use oil to lubricate their internal parts. After a period of time, this oil breaks down and becomes less effective which can cause increased friction and wear. Check the manufacturer’s guidelines for the recommended frequency of oil changes. Many recommend changing the oil every few months or after a specific number of hours of use.

When changing the oil, use the type specified in your vehicle’s manual. Old oil can contain sludge and dirt, which can affect performance. Changing the oil on time helps keep your air compressor efficient, making it run smoother and last longer.

2. Industrial Air Compressors

An industrial air compressor is crucial in many manufacturing and production settings. They handle heavy workloads, providing a steady supply of compressed air for tasks such as powering pneumatic tools and operating packaging systems. Their strength and reliability increase operational efficiency and productivity.

Regular maintenance is crucial for keeping industrial air compressors running efficiently. It reduces downtime, which can be costly. Apart from routine care, investing in advanced monitoring systems can help to track performance and spot problems early, allowing for timely maintenance.

3. Cleaning Air Filter

A clean air filter is necessary for optimal performance of air compressor. Dust and debris can accumulate quickly, restricting airflow and placing stress on the engine. Regularly clean the air filter according to the manufacturer’s instructions.

Cleaning typically involves removing the filter and using compressed air to blow out dust or using a soft brush. Sometimes, you may need to replace the filter if it shows signs of wear and tear. Keeping the air filter clean not only improves performance but also helps save energy by preventing unnecessary power use.

Also Read: How to Change Your HVAC Air Filter?

4. Regularly Condensate Drain

Air compressors can create moisture while running, especially in humid climates. This moisture can accumulate in the tank, leading to rust and corrosion if not properly drained. Most compressors have a drain valve that you should open regularly to release any trapped moisture.

It’s best to check and drain the tank after each use or at least once a week. This simple step protects the compressor and ensures the air produced is clean and dry. If you forgot to drain tank, it can lead to severe damage over time.

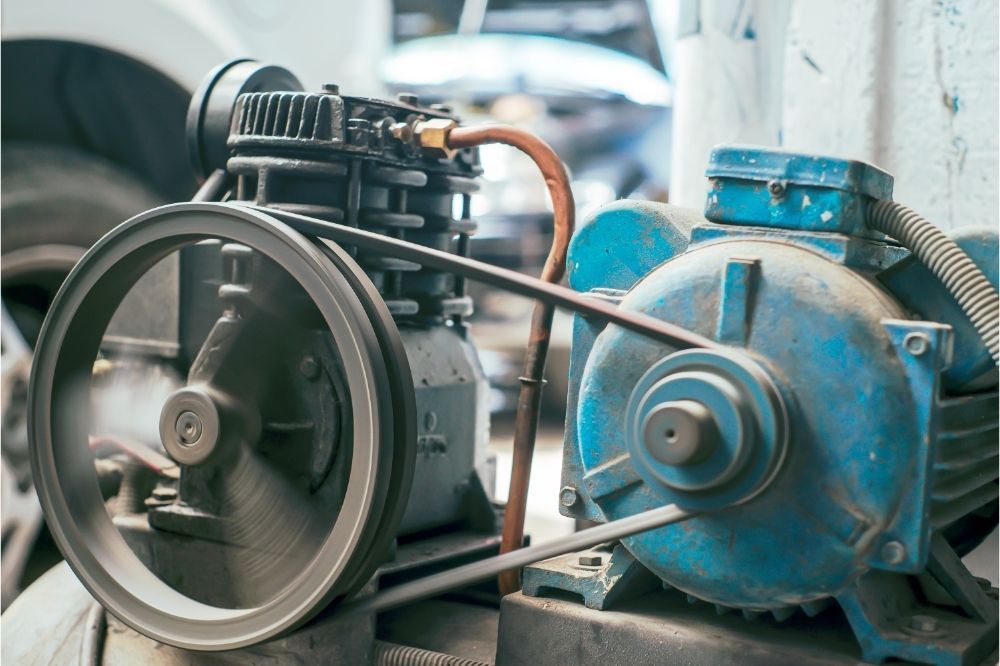

5. Belt Maintenance

If you are using a belt-driven air compressor, keep the belts in good shape is necessity. After some time, belts can wear out, fray, or even break without proper care. Periodically check the belts for wear and tension.

If a belt appears loose or damaged, replace it immediately to prevent further issues. Properly tensioned belts help the compressor run efficiently, allowing the motor to operate effectively and maintaining steady airflow.

6. Check the Electrical Connections

Ensure that all electrical connections should be secure and free from corrosion. Loose or corroded wires can cause an irregular power supply, resulting in the compressor running in-efficiently. Always turn off the power to the compressor before you start maintenance to avoid electrical hazards.

Also, check the power cord and plug for any damage, as this can create safety risks and impact performance. If you notice any issues, it’s best to have a qualified technician repair the electrical connections.

7. Professional Servicing

Some maintenance tasks need expert help. Scheduling regular professional servicing is an excellent way to keep your air compressor in top condition. Technicians can perform thorough inspections, identify hidden issues, and offer repairs that may not be apparent during basic checks.

Hiring a professional can save your money by preventing bigger problems occurring due to neglecting more minor issues. They can also provide tips specific to your model and how you use it, helping you maximize the value of your investment.

Conclusion

By following above-mentioned air compressor maintenance tips, you can keep air compressor reliable for both home and industrial tasks. Establishing a routine helps maintain the compressor’s condition and ensures your workspace functions smoothly. Your simple actions can lead to significant improvements in your compressor and overall maintenance routine.

Also Read: What is Your Air Conditioner’s Compressor?

FAQs on Air Compressor Maintenance

1. Can You Perform All Maintenance Tasks Yourself?

Basic tasks like cleaning filters and draining condensate can be done at home, but complex issues such as electrical repairs should be handled by a professional only.

2. What Happens if You Skip Regular Maintenance?

Neglecting maintenance can lead to reduced efficiency, frequent breakdowns, and a shorter the life of compressor.

3. How Can You Extend the Air Compressor’s Lifespan?

You need to follow a consistent maintenance routine including oil changes, filter cleaning, draining moisture, and regular inspections – to keep it running efficiently for years to come.