Ordinary Portland Cement (OPC), which is the main ingredient for concrete production, contributes to about 10% of the global carbon dioxide (CO2) emission. Nearly 40% of the world’s global emission is due to the construction sector and with the rising number of buildings every year, it is estimated that that only 40% of the infrastructure is built at present and the rest 60% is yet to be built. This means more pollution is yet to be faced by the world. Thus, there is a need to shift industrial dependency from cement to some other alternatives that are environment-friendly and sustainable.

Geopolymer concrete has now emerged as a possible replacement to the binders for the production of concrete. The Geopolymer concrete has also brought about a reduction in CO2 emission in OPC production by 80%.

What Is Geopolymer Concrete?

According to ‘N. P. Rajamane, M.C. Nataraja & N. Lakshmanan’ (Authors of Article – An introduction to geopolymer concrete, which has published in Indian Concrete Journal), Geopolymer cement concretes (GPCC) are inorganic polymer composites, which are prospective concrete with the potential to form a substantial element of environmentally sustainable construction by replacing/supplementing the conventional concretes.

Composition of Geopolymer Cement Concrete Mixes

Following materials are generally used for the production of Geopolymer cement concretes:

1. Fly Ash

2. Fine Aggregates

3. Coarse Aggregates

4. Ground Granulated Blast Furnace Slag (GGBS)

5. Catalytic Liquid System (CLS) –

It is an alkaline activator solution (AAS) for Geopolymer cement concretes (GPCC). It is a combination of solutions of alkali silicates and hydroxides, besides distilled water. The role of alkaline activator solution is to activate the geopolymeric source materials (containing Si and Al) such as fly ash and Ground granulated blast furnace slag (GGBS).

Constituents of Geopolymer Concrete

The main constituents of Geopolymer concrete are:

1. Fly Ash- rich in Silica and Aluminum

2. Sodium Hydroxide or Potassium Hydroxide

3. Sodium Silicate or Potassium SilicateRegarding the strength, one of the main parameters influencing it is the type of aluminosilicate precursor. Some of the aluminosilicate binders require heat curing, which increases the cost of construction. It has been observed that the early strength can be improved by the amalgamation of slag in the geopolymer binder. It has also been observed that the products of geopolymer mortar hydration are calcium silicate hydrate gel and ettringite.

According to ‘Mohd Mustafa Al Bakri Abdullah et al’ (Authors of Article – Comparison of Geopolymer Fly Ash and Ordinary Portland Cement to the Strength of Concrete, which has published in Journal of Computational and Theoretical Nanoscience ), Fly ash-based geopolymer concrete can produces more compressive strength than OPC concrete on days 1, 7 and 28. In addition to that, geopolymer concrete is more resistant to corrosion, acid attack, and chemical attack.

Geopolymer derives its structural strength from polycondensation, and not from the development of Calcium Silicate Hydrate gel, as in OPC. With the advent of industrialization, industrial wastes such as fly ash, ground granulated blast furnace slag, rice husk ash, and other industrial waste products are dumped into landfills, which is harmful to the environment. These are sources of pollution and degradation. Since geopolymer concrete requires raw materials with high aluminosilicates, the consumption of these industrial materials in the production of geopolymer concrete will reduce the pollution burden on the environment, leading to both economic and environmental advantages.

Geopolymer concrete possesses similar mechanical properties to OPC concrete and has been found to perform better than OPC concrete when exposed to fire or harsh environments. However, unlike OPC concrete, on which many years of functional studies were conducted to provide a basis for design codes, geopolymer concrete is still in its nascent stage. It requires long-term researches on its mechanical and durability properties in actual field applications.

Here’s a video to sum up all the points mentioned above & below:

Early Strength Properties of Geopolymer Concrete

Based on experimental results of Geopolymer concrete, some of the points observed regarding its early strength are –

1. In the destructive and non-destructive tests, It is observed that the water/ binder ratio and alkaline solution/binder ratio are the controlling factors in mix designs of various geopolymer concrete mixes.

2. As per Resrarch paper “Effect of Water-to-Geopolymer Binder Ratio on the Production of Fly ash Based Geopolymer Concrete” developed by ‘SUBHASH V. PATANKAR, SANJAY S. JAMKAR & YUWARAJ M. GHUGAL’, A decrease in strength was observed in Geopolymer concrete as the water/binder ratio increased, comparable to the water-cement ratio in the compressive strength of conventional concrete. Based on this observation, the replacement of Ground Granulated Blast Furnace Slag gave the best results in Geopolymer concrete.

3. When the Ultrasonic Pulse Velocity test was conducted on Geopolymer concrete, all samples’ pulse velocity increased compared to the ordinary one. The geopolymer concrete generally has good quality concrete with slight porosity.

4. The decrease in water content allows the Geopolymerization process, which stipulated for an increase of NaOH and Na2SiO3. Thus, it is recommended to have high concentrated molarity or medium and high grade.

5. It was found that Geopolymer concrete, being eco-friendly, exhibits better early strength properties compared to the other composites. By replacing cement, this eco-friendly concrete is much more advantageous and can be beneficial for industries.

Flexural Behavior of Geopolymer Concrete

When Geopolymer concrete was combined with fly ash, it showed excellent properties when compared to ordinary concrete. For flexural strength testing, materials required were:

- Fly ash of Class F confirming to ASTM C618 – 19: 2019[374] (Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete).

- Instead of natural river sand, graded sand was used.

- Standard tests like Specific Gravity Test, Bulk Density, Fineness Modulus, Compression Test of Cube were conducted.

- For the compression test, three cubes were prepared.

- M40 grade was considered for the preparation of concrete mix.

- 20 mm coarse aggregate was used.

- Superplasticizer was used.

- The alkaline solution, Sodium Hydroxide, and Sodium Silicate were used.

- A water-cement ratio of 0.4 was considered for this mix design.

As a result, the flexural strength with Fly ash came out to be 4.85 N/ mm2, 5.02 N/mm2, and 5.12 N/mm2at the 28th day. Thus, the average flexural strength is 4.99 N/mm2 for the 28th day, respectively. Some other points that are interesting to note are –

1. Conventional concrete gains 65% of its 28 days strength, but with research on this, it was observed that concrete with a high level of fly ash gains 40% to 50% of its power in 28 days.

2. As aging time increased, the strength of Geopolymer concrete increased even to the extent that it exceeded the capacity of conventional concrete.

3. Geopolymer concrete composites are more environmentally friendly than traditional concrete cement mixed with fly ash.

4. Geopolymer concrete composites use a waste by-product like fly ash generated in the coal power plants, which prevents the dumping of fly ash from polluting the environment.

5. Geopolymer concrete composites are cheaper than conventional concrete.

6. Fly ash improves the mechanical properties in Geopolymer concrete, thus making it more robust than traditional concrete.

Performance Assessment of Geopolymer concrete

As far as performance is concerned, industrial wastes such as fly ash, GGBFS, and copper slag, when incorporated with concrete mix, proved to give efficient results like –

1. In the case of Ground Granulated Blast Furnace Slag (GGBS), the workability of concrete decreases with an increase in GGBFS content due to the increase in angular shaped particles in the concrete mix.

2. According to Journal Article “Performance assessment of geopolymer concrete using various industrial wastes” develop by ‘Elsa Paul’, in copper slag, as the workability increases, the use of a superplasticizer can be eliminated.

3. This increase in slag content escalates the compressive strength by accelerating the Geopolymerization reaction because of the dissolution of additional silicates.

4. When both fly ash and copper slag are used, geopolymer concrete can be cured at ambient temperature.

5. Geopolymer concrete with fly ash and GGBFS shows higher compressive strength than concrete having a combination of fly ash, GGBFS, and copper slag. Due to high reactive slag particles in GGBFS compared to copper slag, more hydration products are generated for the fly ash and GGBFS mix that fills the porous structure.

Geopolymer Concrete’s Durability Concern

With regards to durability, some of the observations are –

1. In most cases it has been seen that the durability of geopolymer concrete is more than ordinary concrete.

2. Geopolymer concrete has less loss in strength and slight erosion in acid, sulphate, and chloride solution, along with little surface cracklings occurring after high temperature exposure.

3. Geopolymer concrete after carbonation has a lower tendency of reaction and lower mechanical properties mainly due to a higher Ca/Si ratio of C-S-H gel of ordinary concrete.

4. As per Journal article “Geopolymer concrete durability subjected to aggressive environments – A review of influence factors and comparison with ordinary Portland cement” by ‘Keyu Chen et al’, it has been seen that calcium content is mainly responsible for durability in geopolymer concrete.

High-calcium alkali-activated systems have similar erosion mechanisms to ordinary concrete due to the resemblance of hydration products, while the degradation of low-calcium alkali-activated systems involves the exchange of ions between network structure and solution. It also involves transformation of pore solution subjected to aggressive environments. Here, the choice of aluminosilicate source materials has a significant effect on durability.

5. Two factors can be used in geopolymer concrete for increasing durability of geo-polymer concrete good compaction (with the inclusion of various fibers, fine particle, etc.) and another one is to modification in chemical composition (such as the involvement of nano-scale components, biological admixture, etc.)

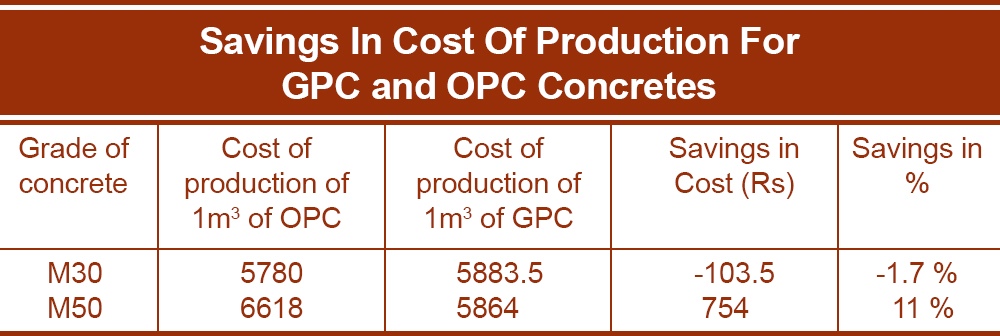

The cost savings can be calculated by comparing the cost of producing 1m3 of ordinary Portland cement (OPC) to the cost of producing 1m3 of geopolymer concrete (GPC). As per the research of ‘J.Thaarrini & S.Dhivya’[375] (Authors of Article – Comparative Study on the Production Cost of Geopolymer and Conventional Concretes, which has published in International Journal of Civil Engineering Research), The following results have been found.

It has been observed that the cost of production of ordinary concrete is higher than the cost of production of Geopolymer concrete for higher grades. For M30 grade, the price of production of Geopolymer concrete is comparatively 1.7% higher than ordinary concrete of the same quality.

For M50 grade, the cost of standard concrete is 11% higher than Geopolymer concrete of the same grade. Thus, the price is economical in the production of Geopolymer concretes of higher rates and lower grades has a marginal difference.

How does Geopolymer concrete perform as compared to ordinary concrete?

Some of the comparisons between Geopolymer concrete and ordinary concrete is as below –

1. According to the ‘Mohd Mustafa Al Bakri Abdullah et al’ (Authors of Article – Comparison of Geopolymer Fly Ash and Ordinary Portland Cement to the Strength of Concrete, which has published in Journal of Computational and Theoretical Nanoscience ), the fly ash-based geopolymer concrete density is in the range of 2290 – 2460 kg/m3, whereas the density of ordinary concrete is found to be 2200 – 2400 kg/m3. Thus Geopolymer concrete has a higher density compared to regular concrete.

2. It was observed that the highest compressive strength of fly ash-based geopolymer concrete could be seen up to 49.3 MPa at 28 days when 30% of fly ash was used. However, the highest compressive strength of ordinary concrete was 31.0 MPa at 28 days, lower than geopolymer concrete.

3. Water absorption capacity of geopolymer concrete is in the capacity of 0.4 – 1.0%, whereas ordinary concrete exhibited water absorption of 1.3 – 2.5%.

4. Ordinary concrete has high porosity of 3.0 – 5.1%, whereas, for fly ash-based geopolymer concrete, the porosity is in the range of 1.0 – 1.9%.

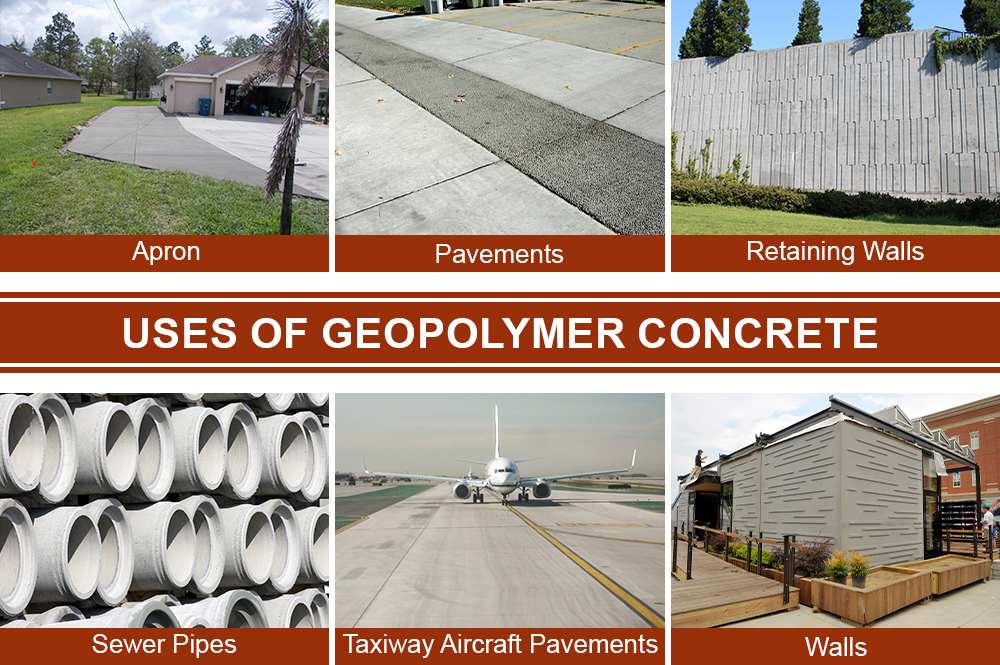

Where Can Geopolymer Concrete Be Used, And Where Is It Recommended?

Geopolymer concrete can be used in pavements, sewer pipes, retaining walls, apron, and taxiway aircraft pavements, and many more. It can be used in places where ordinary concrete is used as it resembles regular concrete in various ways. Because of their excellent heat-resistant properties, they can be used to build fire-resistant homes that provide more safety to the occupants than conventional concrete. It can also be used in water tanks built overhead or underground in case of high-rise buildings.

Conclusion

Geopolymer concrete is new, and not many people are aware of it because of changes in mix design proportions or lack of research. But this doesn’t mean this concrete is less than any ordinary concrete. It is evident from the above facts that it has more strength and durability than conventional concrete. The only problem is the cost criterion, which again can be solved by extensive experiments and modifications in the composition or by replacing the current ingredients with future ones. Hence, it can be inferred that such concrete could be widely used in the future.

In addition, Gharpedia has done extensive research on other types of concrete. To learn more, Visit the following blogs –

Types of Special Concrete: Uses | Advantages | Properties

Pervious Concrete – A Sustainable Choice in Construction

Polymer Concrete: Its Pros-Cons, Uses & Properties

Image Courtesy: Image 1, Image 2, Image 3, Image 4(b), Image 4(c), Image 4(d), Image 4(e), Image 6, Image 7(a), Image 7(b), Image 7(c), Image 7(d), Image 7(e), Image 7(f)

Author Bio

Nafisa Nazneen Choudhury – Nafisa Nazneen Choudhury is a Civil Engineer (completed B.E. from Assam Engineering College) and is currently pursuing M.Tech in Structural Engineering at National Institute of Technology, Silchar. She is a Technical Content Writer, having over 3 years of experience and has wrote many articles related to Civil Engineering. She is also a Book Author (Authored – “Dream Tales of NNC: Revenge By Murder”) and her book can be found on Amazon. She is also a Guest Author at Gharpedia. Moreover, she is a certified member at Institution of Civil Engineers (ICE) and National Society of Professional Engineers (NSPE). She writes her blogs at her website – nnc2017.wordpress.com. She can be reached on LinkedIn.