Glass block is a popular building material that is commonly used for partition work. Glass blocks can look attractive when placed strategically combining with artificial and natural lights. Depending on the transparency of the glass, these glass blocks can be used in places where you need to have privacy. Glass blocks are also used for creating dramatic aesthetic effects. However, you need to choose the glass blocks carefully, because the transparency of light through glass block depends on the pattern of glass block used and accordingly produces different effects.

As the demand for energy-efficient buildings is increasing, these glass blocks come in handy. They provide energy efficiency, sound control, security and even visual texture. The glass blocks can be used in commercial as well as residential projects, as non-load bearing walls, windows, or partitions.

Let us see everything about glass blocks.

What is a Glass Block?

According to ‘Francis D. K. Ching’ (Author of book called Building Construction Illustrated), Glass block is a translucent, hollow block of glass with clear, textured, or patterned faces, made by fusing two halves with a partial vacuum inside. It is also known as a glass brick. It is a building material made from glass and its appearance can vary in colour, size & texture.Use of Glass Blocks in Home:One of the primary reasons for the use of glass blocks in residential buildings is to provide light to the interior. It can be used as façades, partitions, windows, staircase railings, and non-load bearing exterior and interior walls, etc.

Glass block can be also used in some interior work such as a contemporary shower stall, a kitchen island or kitchen backsplash, or decoration with the front door.

01. Use of Glass Block as a Façade

The façade is an elegant component that helps to determine the unique architectural aesthetics of the building. Also, it has a critical role in energy performance in the building. Glass blocks can be used as a façade in the house for energy saving.

02. Use of Glass Block as a Partition

The room partition created with glass blocks allows more light to flow around the room brightening up dark spaces. They can also control the room temperatures by heat retention.

03. Use of Glass Block as a Window

In bedroom, bathroom, or other areas that require privacy, glass blocks can be used in the formation of the window.

04. Use of Glass Block as a Staircase Railing

Glass block can be used as the staircase railing because it helps to transform light. Therefore, artificial light is not required during the daytime. Also, it is easy to clean than ordinary glass.

05. Use of Glass Block as a Wall

Nowadays, houses and offices build have to satisfy the requirements for energy saving. Therefore glass blocks can be used in the formation of a wall because it can transmit the light and reduce the heat, which will reduce energy needs and save your money.

06. Use of Glass Block as a Shower Stall

Glass blocks are used in the bathroom because they provide privacy while the light is passing through and easy to clean.

07. Use of Glass Block as a Bar in Kitchen

Glass blocks can be used in the kitchen to form the bar for breakfast, lunch & dinner. You can achieve the desired height and width by using glass blocks as needed.

08. Use of Glass Block as a Kitchen Backsplash

A Glass block makes smart kitchen backsplash for a kitchen island. The purpose of using a glass block in kitchen backsplash is to protect the surface against any splashes. Also, it can be easily wiped clean without a problem.

09. Use of Glass Block as a Front Door Decoration

Glass blocks are used in the front door decoration because its textured finish provides privacy while still admitting light into the foyer.

Other Uses of Glass Blocks:

- The main reason to use glass blocks in a commercial building is its ability to bring daylight. As a new modern material, glass block helped companies project the image that their goods and services were up – to – date and of the latest fashion.

- It has been used in offices, subway terminals, parking garages, and gymnasiums, in addition to numerous private and commercial new construction and renovations.

- Glass blocks also found popularity in institutional and civic projects. In places like schools, colleges, and hospitals, glass block is providing an abundance of daylight with no glare, which is useful for both students and surgeons alike.

Advantages of Glass Blocks

01) Allows Natural Light to Pass

Depending upon the cutting pattern of the glass, different percentages of light transmission is possible. While transmitting light, the rays are distorted and diffused, which reduces glare.

02) Privacy

While light is passing through the glass block, it provides privacy. They are more secure than ordinary glass because of their thickness.

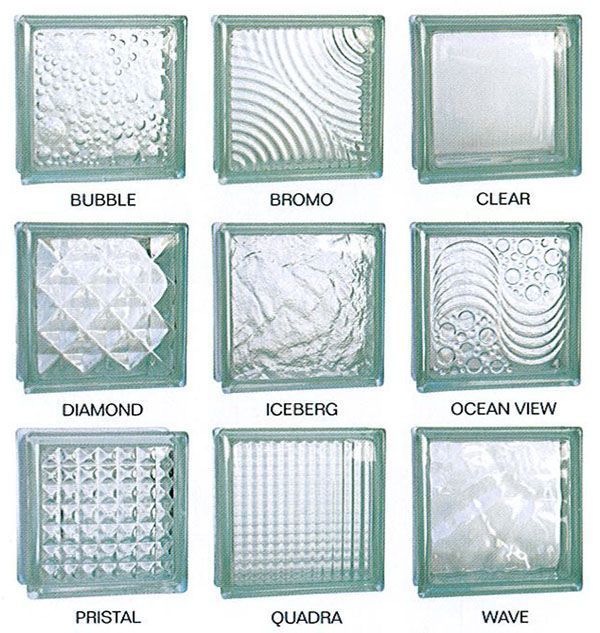

03) Comes in a Variety of Options

Glass blocks come in a variety of standardized dimensions; therefore, purchasing and installation become easier. As more patterns began to be introduced, owners and architects have multiple design choices.

04) Provide Security and Durability

Glass blocks are resistant to cracking and deterioration even though they are not load-bearing. Also, glass blocks are easy to clean due to the non – porous surface.

05) Provides a Good Thermal and Sound Insulation

The partial vacuum in the centre of the block works to retard heat rays and help to maintain the temperature of the building’s interior.

06) Extremely Resistant

Impact Resistance:

- Glass blocks are stronger than conventional glass because of the thickness of the faces and the mortar that binds the blocks together. Glass blocks are more difficult to break and, therefore, provide resistance and are a deterrent to forced entry and vandalism. Glass block units of solid 2 inch provide the greatest resistance to breakage and are ballistics-tested and qualified to UL levels 1, 2 and 6.

- In glass block system with mortar, single blocks can be replaced at minimal expense compared to conventional glass, which requires replacement of the full pane or panel.

Earthquake Resistance:

- Glass block panel has two attributes that make them safe in earthquakes. One of them is their rigidity relative to a tall building’s rigidity. When glass block is used in a high-rise building the panels experience earthquake motions that cycle back and forth very slowly relative to the vibration frequency of the glass block. Therefore, the glass block’s stay stable during an earthquake motion. The second attribute is the rigidity of the glass block panel relative to the rigidity of short buildings or residences. Generally, the vibration frequency is greater than the more severe vibration frequency of the earthquake ground shaking. Therefore, earthquake g – force is not amplified or turned into the ground motion as other architectures, such as chandeliers or bookshelves.

07) Green Building Credits

- Glass blocks clearly fits in the green building design. It provides excellent light transmission and reduces the amount of energy needed for electricity to light a building’s interior.

08) Safety and Environmental Benefits

- The glass block has a unique property that makes it safe and environmental friendly. Glass block plays an important role in green building and contribution to several categories in LEED certifications—both in quantifiable and qualitative measures.

- Glass block has low life cycle impact, as it is recyclable and manufactured from unlimited natural resources. Moreover, glass block is manufactured from 100 percent glass, it does not emit any harmful volatile organic compounds (VOCs).

09) Fire-Protection

- There are no glass block assemblies that qualify as fire-rated wall assemblies. So, the test is carried out only to determine the structural soundness of glass assembly and prevent the passage of smoke and other noxious fumes during the fire test.

- All fire-rated glass blocks available in the market meet a 45-minute or longer duration test. Thicker faced glass block and solid units are available with ratings of 60 minutes and 90 minutes.

How to Choose Glass Blocks

Choosing glass block is an interesting as different patterns have different benefits. For example, a glass block with smooth finish offers high visibility and light transmission whereas wavy and fluted patterns allow for moderate levels of visual privacy while maintaining high light levels.

If you’re looking for a suitable glass block that can provide complete privacy, then go for stippled, diamond, and tightly ribbed designs. There is the provision of fibrous glass inserts that gives maximum privacy and prohibits light and heat transmission.

Glass Block Wall

The glass block is typically bonded with mortar, so it does not require any maintenance or special care. Therefore, the durability of glass blockwork is more. In conventional glazing system or window the whole glass panel requires replacement upon the damage whereas glass block wall or window requires a single block replacement. Many glass block partition installations are over 50 years old, well beyond the typical life cycle of a window. This fact shows considerable savings in material and maintenance.

Surface Condensation:

The glass block assembly is considered to be resistant to surface condensation because of its double face and partial vacuum construction of hollow glass block. Moreover, glass blocks are considered condensation-free to minus 15 degrees Fahrenheit and thin blocks to minus 8 degrees Fahrenheit. But for single-glazed flat glass, condensation can occur when the exterior temperature reaches 33 degrees Fahrenheit. The light transmission property of glass block is nearly equal to that of flat glass.

Tips While Using Glass Blocks in Masonry

01) Non-load Bearing

Glass block walls are thin. Glass blocks do not have the load-bearing capabilities like other masonry products; it can only carry its own-weight. Therefore, while using glass panels into openings, provisions must be made to support the construction above.

The structural support system should assure that the load from the surrounding wall is not transferred to the glass panel and that the possible deflection of the supporting members does not crack the panel. Also, adequate provisions must be made for differential movement between the glass and the surrounding wall.

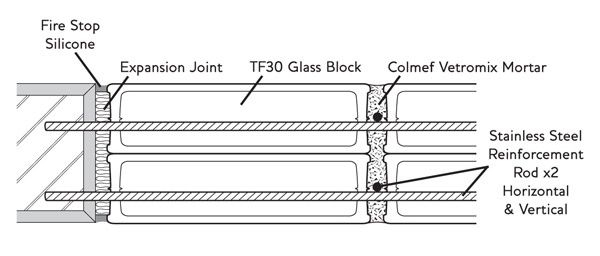

02) Mortar Considerations

The glass block is non-porous material and does not absorb any moisture like other masonry products. Therefore, the consistency of glass block mortar must be stiffer (like peanut butter) than the wetter mortar used with other masonry products.

All bed joints must be filled with mortar, and all joints must be finished smooth to prevent penetration of moisture. Almost all building codes allow the use of Type “S” or “N” mortar with glass unit masonry construction. The “S” mortar is recommended for exterior applications and it consists of 1-part Portland cement, 1/2-part lime, and sand equal to 2-1/4 to 3 times the amount of cementitious material (cement plus lime), all measured by volume. For final cleaning, common mortar-removing chemicals (muriatic acids of any strength) should not be used.

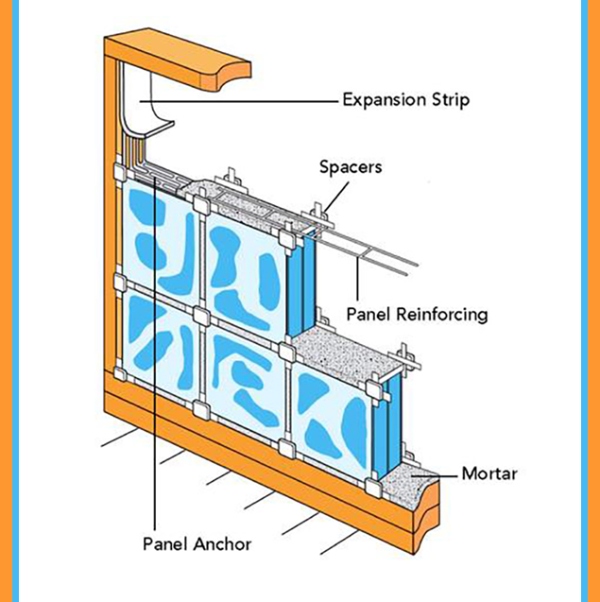

03) Expansion Joints

To allow any movement of the glass block, expansion strips 3/8-inch thick, are required along the top and sides of glass block panel filled with a resilient material like polyethylene, which makes panel to expand and contract. In exterior walls, joints must be well packed to prevent water penetration.

04) Panel Reinforcement

A glass block wall or partition needs a horizontal joint reinforcement which is important to control cracking due to expansion and contraction. This horizontal reinforcement should be spaced no more than 16 inches on center and extend horizontally along the length of the panel.

Materials like stainless steel, galvanized iron, 9-gauge steel, etc. can be used for reinforcement. Ladder-type reinforcement is made of two parallel wires with butt-welded cross wires at regular intervals. The joint reinforcement is pressed into the partially filled mortar joint, then covered with the remaining mortar and troweled smooth. Mortar joints should not be furrowed.

05) Panel Anchoring

Anchoring glass block panels are essential to accommodate lateral support along the top and sides of each panel. Panel can be anchored by three methods panel anchor, channel, and chase systems. These anchoring supports are designed to resist the applied loads, or a minimum of 200 pounds per lineal foot of panel, whichever is greater.

The material for panel anchor can be stainless steel or hot-dipped galvanized steel. Panel anchors tie glass block panels into the surrounding frame at head and jamb locations. Anchors are generally placed at a maximum of every 16 inches on center.

Disadvantage of Glass Block

- A glass block does not provide adequate natural ventilation inside the building.

Comparison between Glass Blocks and Ordinary Glass

Glass is an ancient transparent building material, which facilitated penetration of light into building. Once it was used exclusively for window, whereas nowadays there are examples of structures made of glass. Apart from the non-load bearing application in building it is used for construction of load bearing elements, too. While glass block is translucent building material made from glass. It is also used in home as a non-load bearing elements.

Glass Block Manufacturing

Manufacturing of Glass block is simple. Silica sand, soda ash, and limestone are mixed and melted in tanks heated to 2,300 degrees Fahrenheit. Then a precise amount of molten glass is poured into a half-block mold and two halves are sealed together, creating a partial vacuum within the unit, and then fed into an oven to slowly cool and in the process, strengthen.

Later, each glass block is treated with a special edge coating of polyvinyl butyral to increase mortar bond and allow for expansion and contraction. Each glass block is then tested for clarity and consistency. The glass block unit can be hollow or solid and can come in a variety of sizes, shapes, patterns, and textures.

Different Shape and Size of Glass Blocks

The glass blocks come in variety of sizes, shapes, pattern and textures like bubble, diamond, iceberg, pristal etc. The mostly used glass block units are square having 6”, 8” or 12” sizes and rectangular units having 4 X 8-inch and 6 X 8-inch size. A bull-nosed edge blocks for finishing horizontal and vertical panels, and various corner and angular blocks are also popular.

Cost of Glass Blocks

The cost of glass block wall as compared with ordinary glass is more.

Conclusion

According to The American Institute of Architects, Glass block is a building material whose many applications exhibit its multifaceted characteristics. The varying forms of glass block, like its type, thickness, size, shape, and patterns, along with the method of installation, can be combined to create unique design solutions.

If you are constructing a new workspace or are planning an office refurbishment, you will need to consider how to divide your office space. Glass block partitioning can be used in commercial spaces, schools and offices – it is even becoming popular in modern homes. It is the ideal option if you are looking for workspace with open spacious feel, but at the same time provide an element of privacy.

Glass Blocks can be used as facades, windows, interior partitions, etc. In all applications, it permits the control of natural and artificial lights and thermal transmission. Glass blocks are impact-resistant and can assist in privacy applications.

Image Courtesy: Image 1, Image 2, Image 3, Image 4, Image 5, Image 9, Image 10, Image 11, Image 12, Image 13

Author Bio

Bhushan Mahajan