What is Grasscrete?

Grasscrete is an environmental friendly solution that offers us an impervious pavement for emergency vehicle access, parking and water management applications. Grasscrete is manufactured by a simple process by pouring concrete over styrene void formers. It is thus a cast on site cellular reinforced concrete system with void created by formers. Former is fundamentally equipment or a mould that forms voids in the concrete, which can be filled later with a variety of porous materials such as stone, gravel or vegetation.

Thus, Grasscrete is a cast on site cellular reinforced concrete system with voids created by plastic formers. It is also known as void structured concrete. It has definite pattern of voids formed with the help of disposable forms, which when removed and replaced with grassed soil or stone allows water to percolate through the concrete. The previous nature of Grasscrete is consequently not obtained by using some chemical admixtures, but with a predefined mechanical system, to create voids in a systematic, regular pattern.

It uses single-use forms so as to create monolithic reinforced ready mixed concrete pour. It thus gives a pervious pavement structure. After the concrete hardens, the voids are opened and are either filled with crushed stone or vegetation.

The pavement structure can be used round the year without compromising the beauty. It is therefore a sustainable product which largely uses recycled material. It is also frequently used to earn LEED* points due to reduction in heat island effect, efficient stormwater management, long life span and low maintenance. It thus offers significant advantages over precast concrete and plastic paving system.

The formers used in Grasscrete are generally of two types:

01. Reusable Plastic Mould which can be used only for concealed Grasscrete or fully grassed installations.

02. Single Use Moulded Pulp Former which can be used for all types of Grasscrete.

Importance of Grasscrete

The unique properties of Grasscrete reduce the number of construction operations, thereby giving better flexibility.

To understand this further, let me give you a comparison to demonstrate the importance of grass over a typical tar blacktop car parking.

Under a typical car park, a complex infrastructure must be completed before the actual service covering can be laid. Imagine a system that requires no curbs or edge restraints. Another costly headache – the surface water drainage system can be eliminated. And the benefits do not stop here, by replacing the tar with load-bearing Grasscrete, the sub base and its excavation will be reduced.

Grasscrete provides a working solution to a variety of applications with its unique fully enclosed pocket shape enclosure. It also provides an even platform for vehicles or pedestrians.

The importance of Grasscrete in various aspects is explained below in detail:

Structural Stability of Grasscrete:

It has its own solid concrete structural edge allowing the surrounding ground levels to blend naturally into the surface without unsightly upstands. The structure of Grasscrete is self-draining, enabling rainwater to discharge naturally to ground. The peak demands on sewers and storm channels is therefore reduced permitting new developments to be planned without costly drainage works either on or off site.

It is Self-Draining and Resists Differential Settlement:

This self-draining capability helps in preserving the natural look of the landscape, thereby providing a perfect aesthetic outlook to the whole thing. However appealing the landscape may be, there are occasions when it has to perform under the harsh realities of daily life.

Just like Grasscrete, hardscaping also furnishes an aesthetic appeal to your home. Are you interested in knowing more about hardscaping? Read the following blog to explore more.

Unlike grass and precast concrete block system, which may not function under loads Grasscrete is a fully reinforced in situ structure providing an ideal loading platform to resist differential settlement. The natural drainage capability of Grasscrete is of major benefit here too, enabling high volumes of fire fighting water to be dispersed without the loss of surface strength.

Provides Safe Emergency Access:

The provision of safe emergency access and escape must ideally be allowed in the design of any building. The probable infrequent use of an access route should never be the determining factor in its design. In naturally grassed areas, the load-bearing capability of soil can never be predicted, even disregarding the effective rainfall. Such areas are practically incapable of bearing the weight of fire appliances.

A life emergency situation is not the time to test the suitability of the emergency access route. A fire access route must be capable of sustaining not only the load of a moving appliance, but also the imposed load of static equipment.

Grasscrete is therefore the right environment friendly response to emergency access problems.

Types of Grasscrete

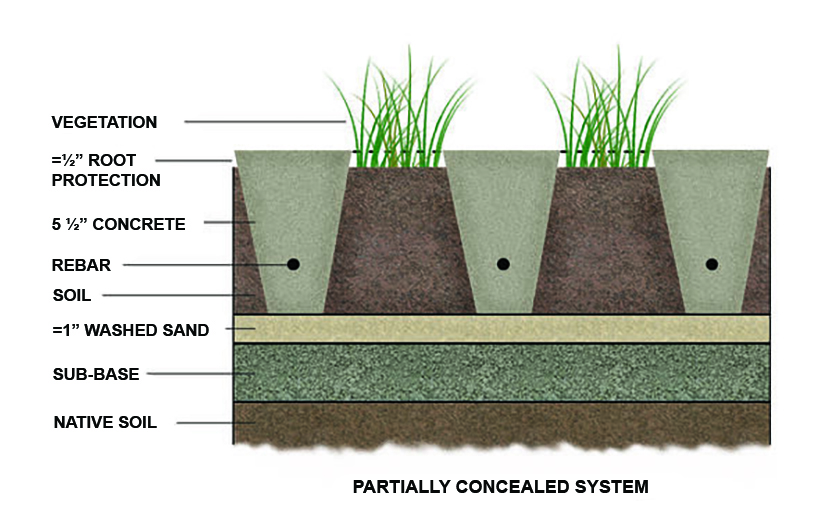

Partially Concealed Grasscrete:

In partially concealed concrete, the vegetation is arranged parallel to the concrete. Concrete of five and a half inch thickness is provided along with half an inch root protection alongside the vegetation.

Partially concealed Grasscrete is ideal for sustained traffic areas. In addition to this, due to the presence of vegetation, it is functional, environmental friendly and pleasing in appearance.

Common Partially concealed applications include:

01. Vehicle parking

02. Access roads

03. Road shoulders

04. Driveways

05. Fire and emergency access

Concealed Grasscrete:

In concealed Grasscrete, there is a layer of soil of depth 1 inch above the concrete. The concrete below this layer of soil is concealed and has a depth of five and a half inch. The vegetation is laid above the layer of soil. This type of Grasscrete is ideal for low traffic areas.

Common concealed Grasscrete applications include:

01. Fire and emergency access

02. Overflow vehicle parking

03. Low traffic access roads

04. Medians

Well, Grasscrete is one of the options for the pavement of your home. There is another option which is paver blocks which can also be considered for the pavement of the home. If you want to know in detail about paver blocks, click on the mentioned Gharpedia’s blog.

Stone Filled Grasscrete:

In stone filled Grasscrete, the soil between the concrete is replaced with crushed stone. The thickness of crushed stone is limited to 1/2 inch or ¾ inch. Stone filled Grasscrete is capable of draining at rates of up to 480 inches per hour with 100% retention of water.

This type of Grasscrete is ideal if you are looking for considerably a low maintenance design. Stone filled Grasscrete is perfect for sustained traffic areas. Furthermore, it provides maximum percolation rates. It is both functional and environment friendly.

Common Stone filled Grasscrete applications include:

01. Vehicle parking

02. Access roads

03. Fire and emergency access

04. Military installations

Benefits of Grasscrete

01. Structural Benefits of Grasscrete:

Natural grass combined with the engineering principles of concrete that is reinforced provides an access to a variety of benefits and possibilities. Some of the major structural benefits of Grasscrete are mentioned below:

High Load Bearing Capacity:

One of the main structural benefits of the Grasscrete comes as its high load bearing capacity effective with saturated sub-base. Grasscrete supports up to 114000 pound (51858 kg) vehicles. Moreover, it also supports other applications such as military tank and light speed rail track access; even after the saturation of sub base in Grasscrete.

Resists Differential Settlement:

As we know that a monolithic concrete slab uniformly distributes the weight of load over a larger surface area, thus resisting differential settlement, which is often the case in modular pre-cast or plastic systems. Hence, Grasscrete is considered to resist differential settlement in comparison to the other alternatives.

However, the structural integrity of Grasscrete does not depend upon the vegetation and it can be peddled once the concrete reaches its desirable compressive strength and flexural strength simultaneously.

Grasscrete Withstands Freeze Thaw & Protects Slope:

The unique pocket profiles present in the Grasscrete allows it to release frost heave along with hydro-static pressure. This particular benefit of the Grasscrete helps in demanding slope protection works.

Edge Details not Required:

Systems like modular pre-cast concrete or plastics require edge restraints or curbs whereas, Grasscrete on the other hand requires no such thing. It blends naturally with the adjacent finishes giving an aesthetic outlook.

Lesser Depth for Sub Base is Sufficient:

Considering the thickness of the section and its continuous reinforcement, Grasscrete can be installed with a lesser thickness of sub base than required for the other types of pervious pavements.

Would you like to know more about other pavement material like Grasscrete? Then, here is an alternative for you. In our articles below, we have explained in detail regarding interlocking paver blocks.

What are the Advantages of Interlocking Paver Block?

Did you Know the Disadvantages of Interlocking Paver Block?

02. Economical Benefits of Grasscrete:

Longer Lifecycle:

Grasscrete has a longer lifecycle in comparison to the other conventional impervious paving systems. In fact, Grasscrete has installations that go back in time as far as 1974 that is still in place today.

Reduces Costly Infrastructure;

One of the unique properties of Grasscrete is that, it allows natural water infiltration. And it is also established that treating stormwater is not a practical solution but is also regulated by a number of agencies. Thus, the need for expensive stormwater infrastructure such as curbs, gutters and underground piping can be reduced or even eliminated in some cases.

Low Maintenance Costs:

The most viable option associated with low maintenance cost is the stone filled Grasscrete. It is also the most widely used Grasscrete. Clogging of the voids in areas having slope less than 1% is not typical although, these voids can be cleaned out easily.

Heavy maintenance such as vacuum trucks and regularly scheduled maintenance is not required. When it comes to vegetation, it can be treated normally like it is done for the other grasslands. Additionally, Grasscrete can be easily snow ploughed.

03. Environmental Benefits of Grasscrete:

Increases Green Space and Reduces Heat Island Effect:

Heat islands are nothing but the built up areas that are hotter than the nearby rural areas. The visually appealing green space/vegetation reduces the heat Island effect, thereby creating a comfortable, attractive and a calming parking area for the use of vehicles. This is how Grasscrete allows a barren vehicular area transform into a green urban oasis.

Uses Recycled Materials:

The use of recycled material is encouraged in Grasscrete right from the manufacturing process of the concrete mix to fill the voids and the sub base layers. Grasscrete maintains its environmental focus by utilizing the recycled materials to its 100% capacity.

Infiltration of Storm Water:

Grasscrete not only maintains the natural equilibrium of the groundwater recharge but also significantly reduces the runoff. Infiltration of the stormwater in Grasscrete is at about the same rate as any other ordinary lawn located in the same area.

Furthermore, this infiltration promotes the water quality improvement through bio retention. In this process, the metals and toxins are naturally cleansed through vegetation and soil structure.

Installation of Grasscrete

Preparation:

At the very beginning, make sure that your work space is prepared with edge framework and a consolidated sub base. The construction schedule for Grasscrete to be cast on site is simple and uncomplicated. After removing the topsoil and excavating to reduce the level, an MOT Type-1 sub base is laid. Formwork is erected for the edge and a sharp sand blind covers the sub base. Ensure that there is 10 mm to 20 mm binding layer of sand.

Lay Formers:

Place 600 mm x 600 mm formers edge to edge. The formers can be cut accordingly to fit the space. The Grasscrete plastic formers are now laid adjacent to each other leaving a 100 mm margin at the edge and at the expansion joints.

Mesh Reinforcements:

Place mesh reinforcements on formers. Position the mesh on the up-spacers located between the main up-stand of the former. The mesh needs to be purchased separately. The formers have integrally moulded spacers to support the mesh reinforcement.

Pouring of Concrete:

Concrete is poured into the formers with the help of staging boards. Note the use of flowing concrete. Make sure that the concrete is placed around formers and mesh, and levelled to top of the formers. Squeegees are used to level off the concrete to the top of the formers. The solid margins are towelled and concrete is allowed for 48 hours to harden.

Melt Former Tops with Flame Guns:

The tops of the plastic formers are burnt out with the help of LPG flame gun. Piercing each former top with a long steel pipe is recommended to provide a leading edge for the flame.

Top Soil and Seed:

Fine tribal topsoil fills the pockets in the Grasscrete which is thence watered to allow settlement. Subsequent to the initial settlement, the planting must be watered daily over 2 weeks to establish grass cover. After that, it must be watered as required until the grass grows completely.

Applications of Grasscrete with a Case Study

Today, Grasscrete is not only used in support of traffic units but it is used more and more for an increasing number of its varied applications. It makes a major contribution in the design of slope protection and stabilization systems. Fully tested at high water flow rates of up to 8 meter descendant, Grasscrete is used for embankment and spillway protection.

For instance, at Bradwell Lake in Milton Keynes a project for the Anglian water authority was undertaken. In this mature application, Grasscrete has been used to massive effect as a facing to the embankment and as a surface to the spillway. Grasscrete over this very large area conformed perfectly to the contours to the land. Construction of the site in the year 1972, clearly demonstrates the underlying reinforced concrete strength that only Grasscrete can provide the ideal surface protection in the building of dams and spillways.

It is certainly difficult to identify the Grasscrete as it blends into the landscape, just another example of its function being exactly fulfilled.

Other applications of Grasscrete include:

- Roadways

- Medians

- Pedestrian Access

- Water Management

- Sustained Access

- Fire and Emergency Access

- Daily Parking

- Over flow Parking

Conclusion

Grasscrete is a concrete service that is capable of supporting a 40 ton load because this surface is a unique combination of the natural and the man-made materials.

Grasscrete is a modern yet a socially acceptable innovation. It is providing all the practical solutions in situations where concrete, tar or other materials might be used but, at the same time softening the urban landscape.

Today, all over the world Grasscrete gives the architect, engineer or town planner a new dimension to work with a surface material with the load-bearing characteristics of reinforced concrete and an aesthetic appeal of grass. Such is the versatility of Grasscrete that new applications are constantly being discovered. Furthermore, there are alternatives to Grasscrete such as Grassblock, Grasskerb and Grassroad.

Image Courtesy: Image 1, Image 2, Image 3 – grasscrete, Image 5, Image 6, Image 9, Image 10 – grasscrete, Image 11, Image 12, Image 13, Image 14

Author Bio

Arfa Falak – My name is Arfa Falak and I have my graduation in BE (civil). I live in Bangalore. I am an aspiring design Engineer.