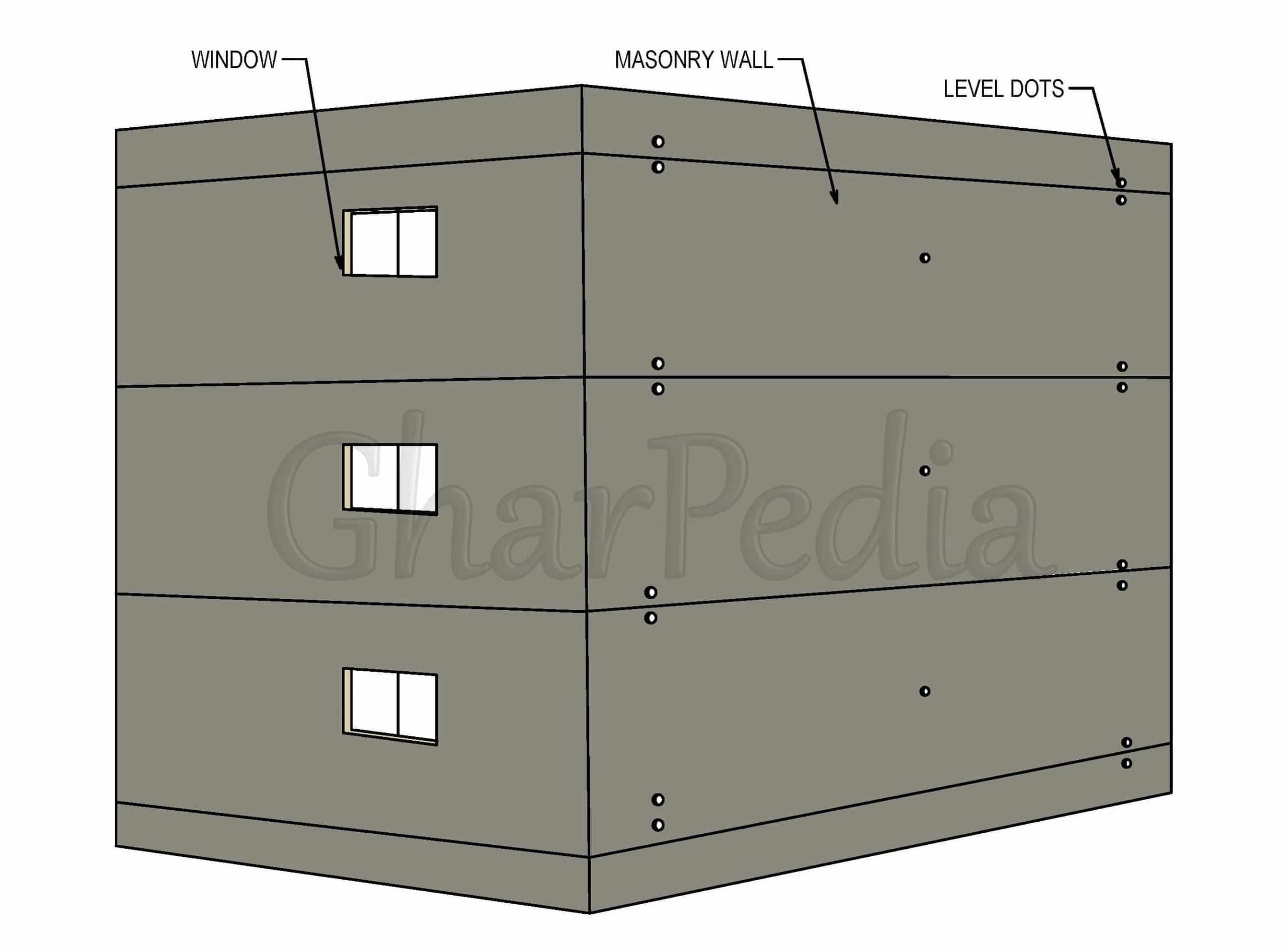

Plastering is one of the most general and ancient finishing techniques. It is applied to give a visually pleasing smooth surface to block or brick masonry of the wall. Plastering not only enhances beauty, but also acts as a protective cover for bricks and stones and protect them from rain and wind. Depending upon desired finishes, ingredients, popularity and required proportion, different types of plasters are used in different works. Different plasters available in market are cement plaster, lime plaster, clay plaster, mud plaster, gypsum plaster etc. In past few decades, gypsum plaster has gained popularity and has largely replaced lime and cement plasters. Here, we are going to discuss about the properties, method of application, advantages and disadvantages of gypsum plaster.

Gypsum Plaster

Gypsum is a soft sulfate mineral containing Calcium sulfate dihydrate (CaSO4:2H20). It is found in the form of rock in nature having white colour. It is widely used in fertilizers, moulds, sculptures and as a plaster material.

History of Gypsum Plaster

Gypsum plaster is not a recent invention. It is in use since centuries in construction field due to its excellent properties. It was used by the ancient Egyptians to plaster the pyramid at Cheops. Usage of gypsum plaster as an internal plaster in the pyramid of Giza of Egypt is a proof of its durability and performance.

According to ‘R. Barry’ (Author of The Construction of Buildings), During the last decades the use of gypsum plaster has increased greatly for both undercoat and finish plaster to the extent that is has largely replaced lime and cement.

What is Gypsum Plaster?

In gypsum plaster, gypsum is used as a binding material instead of Portland cement. Gypsum plaster is a white cementing material made by partial or complete dehydration of the mineral gypsum. When dry gypsum powder is mixed with water it gets hardened. This material can be applied over block, brick or concrete surface to form a smooth surface. It is available in ready to use format and does not need sand. Only the addition of water is required. It offers excellent acoustic and thermal properties while giving levelled walls with the best finish.

Gypsum plaster provides a smooth interior finish and is an ideal base for good quality paints and wallpaper finishes. It can be applied on both smooth and rough surfaces of the wall. Gypsum plaster is easy to apply and requires less skilled manpower unlike the traditional cement mortar. The preparation of surface and application of gypsum plaster should be apt to prevent cracks and peel offs.

Storage of Gypsum

The surfaces exposed to moisture reduces the setting time and strength of gypsum plaster. So, gypsum bags have to be stored on elevated as well as a dry platform made of timber, brick or concrete. The shelf life of gypsum plaster is usually 3-4 months from the date of manufacture. If stored properly under suitable conditions of temperature and humidity, its shelf life can be increased by another 6 months.

Thickness of Gypsum Plaster

It can be applied in the thickness of 6 -20mm. The thickness of undercoat of gypsum plaster is normally 11mm for walls and 8mm for ceiling while that of finish coat plaster is 2mm. It is recommended to apply a minimum thickness of 6mm gypsum plaster to avoid cracks. If more than 20mm thick of plaster built up is required on a wall, then an initial dash coat of cement sand plaster is applied for a thickness of 8-12mm then gypsum plaster for the remaining thickness of not less than 6mm is applied to achieve a smooth finish.

Technical Specification of Gypsum Plaster

- Colour of Finished Surface – White

- Setting Time – 25-30 Minutes

- Coverage Area (12mm thickness) – 21ft2/ bag

- Package Size – Bag of 25 kg

How to Apply Gypsum Plaster/Method of Application

After surface preparation, gypsum plaster is applied in the following way.

- Gypsum Plaster generally comes in ready mix bags. Extract the powder in a clean dry vessel, add water and stir the mixture for 2-3 minutes

- Ensure the thickness of plaster needed is not more than 13 mm.

- Apply gypsum plaster to the surface with firm pressure.

- As the plaster stiffens, carry out further flattening. When the plaster is sufficiently firm, scour the surface with sponge float & water as per requirement.

- Trowel the surface progressively to get a smooth finish.

- Plastered surface should be protected from continuous exposure to moisture.

- Painting work should be started only after the surface has become completely dry.

Types of Gypsum Plaster

There are two types of gypsum plasters based on the amount of heat applied during the production.

- Anhydrite gypsum plaster – manufactured by heating gypsum to 1700C

- Hemihydrate gypsum plaster – produced by heating gypsum to more than 1700C.

Depending on the type of application, gypsum plasters are categorized as:

- Casting Gypsum Plaster

- Undercoat Gypsum Plaster

- Finish Gypsum Plaster

- One Coat Gypsum Plaster

- Machine applied Gypsum Plaster

Properties of Gypsum Plaster

- It is light-weight and hence its usage for plastering does not increase the structural load on the building.

- Gypsum plaster does not shrink during drying and hardening processes unlike cement plaster.

- It is less prone to cracks.

- Gypsum is non-combustible and contains high content of crystal water. In the event of fire, it acts like a barrier and protects the block work, concrete and steel.

- Gypsum plaster prevents rusting of metal fittings like pipes and increases their durability.

- Gypsum plaster has low thermal conductivity and ensures energy and power saving.

- Gypsum plaster gives high tensile and flexural strength.

- According to ‘SP 62: S & T 1997’, (Handbook on Building Construction Practices Excluding Electrical Work), after the plaster is properly set and the plaster backing and backgrounds are dry, it is possible to paint gypsum plaster with any type of paint except cement paint.

Advantages of Gypsum Plaster

- The application of gypsum plaster is a time-saving process, hence cost of the project is reduced.

- Quantum of wastage during application is negligible.

- It is easily workable for an excellent finish.

- Gypsum plaster does not require curing which saves both water and time during construction.

- Gypsum exhibits bonding properties. Hence only a single coat on RCC ceilings, internal bare-brick walls, AAC blocks and concrete columns would be sufficient.

- The space looks large and beautiful as gypsum plaster is pure white in colour.

- Gypsum plaster is pre-mixed material and available in easy to handle packs.

- It can be easily applied and mould into different shapes for decorative purposes, setting time of gypsum plaster can be controlled and also the time gap required between two successive coats is less.

- It gives a smooth finish to the surface to receive all type of paints.

- Various surface textures and surface hardness can be obtained.

- Gypsum plaster is not affected by insects and does not favour growth of fungus.

Disadvantages of Gypsum Plaster

- For the same thickness, gypsum plaster is costlier than cement plaster. But in areas where river sand is difficult to procure, gypsum plaster would be economical.

- Gypsum plaster is undesirable on outside walls since they are prone to dampness and in areas which are continuously damp such as a bathroom, toilet, wash area, kitchen etc.

- According to ‘R. Chudley’ (Author of Building Construction Handbook), cautions against the use of Gypsum plaster in temperatures exceeding 43°C and on frozen backgrounds.

In the end, you have seen that gypsum plaster has so many advantages over cement sand plaster. It gives better finished surface and performance as compared to traditional plasters. Gypsum plaster is also advisable where natural sand/river sand is not easily available for the construction. But it is costly and procuring good quality gypsum is difficult in certain places and hence it is not popular.

Must Read:

Secret Revealed! Why External Plaster is Done in Two Coats?

Reasons behind Cracks in Plaster: An Incredibly Easy Guide

Ready Mix Mortar for Brickwork, Plaster and Repair Maintenance!

Image Courtesy: Image 2, Image 3, Image 5 – comparequotes, Image 6, Image 7