Chipboard is made from waste wood. This wood waste could be wood chippings produced from the milling process, sawdust, or the leftovers from cutting or thinning forest branches. All these materials are made into a slurry by use of urea-formaldehyde and other glues depending on the intended use of the chipboard.

The slurry is then subjected to intense pressure and temperature to remove the liquid and from the board. There are different types of chipboard sheet materials used in varying applications. Continue reading below to understand how is chipboard made step-by-step.

01. What is Chipboard?

Chipboard, also called particleboard, is a panel engineered by compressing small chippings of wood with glue. The primary advantage of chipboard is that it is environmentally friendly. It is manufactured from waste wood that would otherwise have been disposed of, saving forests.

02. How is Chipboard Manufactured?

Here is a step-by-step guide on manufacturing of chipboard:

Step 1: Raw Materials and Pre-Treatment

The largest percentage of chipboard is waste wood. To change wood waste products from their crude form into finished chipboard, several steps are followed. Generally, obtaining the raw materials for the chipboard is not hard since such materials like wood chips and dust are obtained during the manufacture of other wood products. After collecting the raw materials, they are sorted according to sizes and chipped.

Step 2: Chipping, Drying, and Screening

Chipping is meant to make the wood waste uniform (if different wood chip sizes would be needed at a later stage, the dimensions are also made at this stage). Once the chipping process is complete, the uniform wood chips are taken for drying to make sure all the chips have the right moisture content.

With the right moisture content attained, the wood chips are taken through the screening process to assort chips into evenly sized collections.

Step 3: Gluing and Chipboard Formation

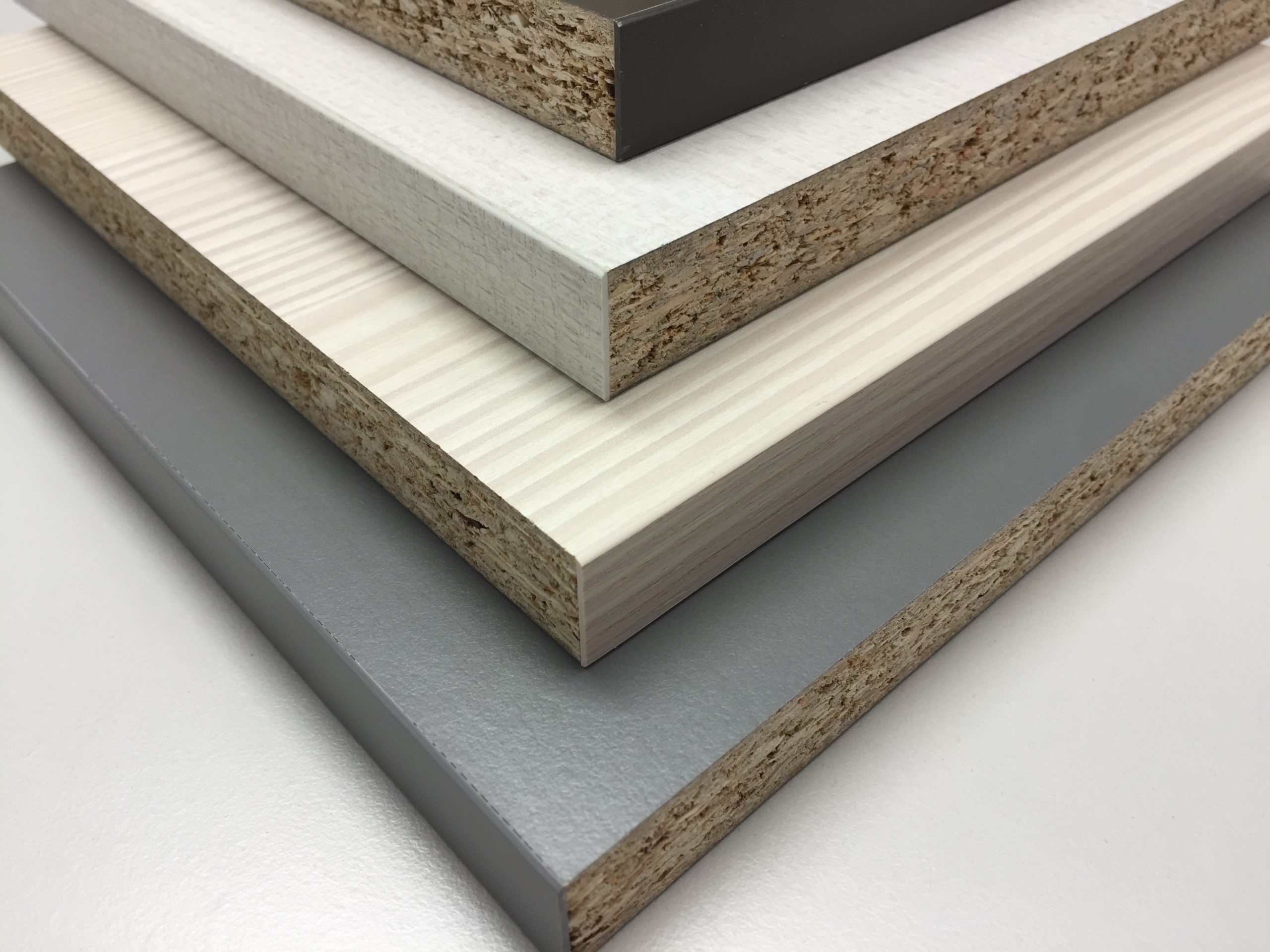

At this stage, different additives and synthetic resins are applied to different sized wood chips. Now the chips can be engineered into the chipboard. Usually, the chipboard has three layers, and those layers are formed at this stage. The big-sized chips form the centre of the chipboard, while the small-sized chips form the outer layers. After the wood chips are correctly arranged according to the format, the panel is sent for pressing.

Step 4: Pressing

The wood chips are pressed under high temperature to get the correct thickness and rigidity of the chipboard. Pressing is supposed to induce the glued chips to bind together tightly, creating an unbreakable bond once the temperatures reduce. After the cooling, the next and the last stage is post-treatment.

Step 5: Post-Treatment

At this stage, the chipboard is engineered to meet the set specifications depending on different projects. It involves a myriad of steps. First, experts sand the surface to come up with a smooth and uncoated surface. The chipboard is then cut to the right measurements of the finished product.After getting the desired dimensions, now the chipboard can be stored and chipped to distribution centres and retailers. Depending on the expected use of the chipboard, it can be laminated before storage. Lamination gives the product a decorative layer.

Must Read:

Particle Board: All You Need to Know!

Advantages and Disadvantages of Particle Board

7 Uses of Particle Board in Building Industry

Image Courtesy: Image 3