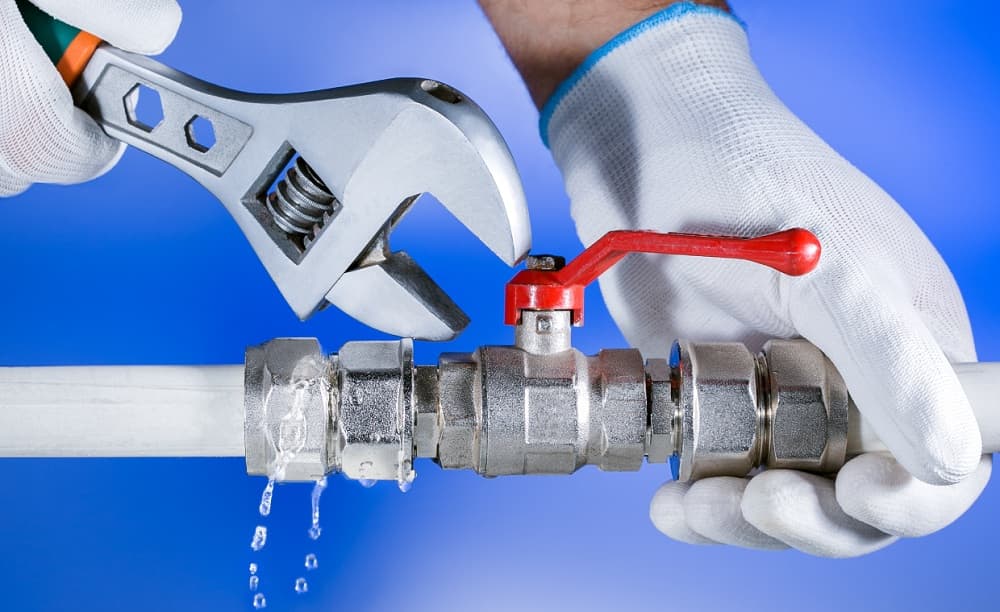

Is your old shut-off valve creating a lot of problems? You don’t need to worry; we’ve got a solution for you: replace it with a compression shut-off valve. They’re easy to install, and there is no need to solder. Also, they rarely leak, lock up, or wear out.

The other good thing about the compression shut-off valves is that you can use them on both plastic and copper lines. After installing a compression valve in your lines, you’ll not stress yourself with its maintenance and inspection; you only need to periodically cycle the valve from the open to close position to prevent it from freezing. We will tell you how to install a compression shut-off valve yourself.

How do Compression Shut-Off Valves Work?

Compression shut-off valves work with a brass compression sleeve that fits in a coupling nut that bolts into the valve’s body. Tighten the nut onto the valve. It compresses the brass sleeve against the copper pipe, forming a watertight seal.

What are the Advantages of Compression Shut-Off Valves?

Since compression valves are known as the original shut-off valves, they’re highly recommended by experienced professionals. Below are the advantages of compression shut-off valves:

01. Easy to Repair

Compression valves have simple repairs, unlike other valves, which you need to replace whenever they break. You don’t need to buy the whole valve; just replace the faulty parts.

02. They’re Durable

A compression valve can last longer if well maintained. However, its durability entirely depends on its construction. The more the parts are stable, the more the valves will likely last a long time. So, when going for one, consider the valve with quality parts.

03. Ease of Use

Compression shut-off valves would go a long way if you want a shut-off valve that requires as little effort and strength as possible when shutting off your application. Unlike other valves, they work the seizing out by only manipulating the handle.

Also, the good thing about the compression valves is that they are easier on your pipes. You don’t have the hammer you experience with the rapid shut-off of other valves like quarter-turn valves. They close at a slow, controlled rate.

Steps for Installing a Compression Shut-off Valve

Can I install a compression shut-off valve on my own? Is that what you are asking? Yes, you can. Installing a compression shut-off valve isn’t rocket science. You only need the right tools and equipment, and you’re set to go. Here is how to install shut-off valves like a veteran:

Compression Shut-off Valve Installation Tools And Material

- Tubing cutter

- Compression sleeve puller

- 2 Channel-lock pliers

- New compression shut-off valve

Instructions for How to Install a Compression Shut-Off Valve

Step 1: Shut the Water Off

- The first step before installing the compression valve is to shut off the water supply to the house. The main water shut-off valve is usually located close to the water meter. If possible, replace the two shut-off valves with a faucet simultaneously, because if one valve is not functioning, the other one will soon follow.

- If you have a gas water heater, you must turn the knob to the pilot position. Then shut the circuit breakers to the electric water heater off. Turn on the faucet on your house’s upper level and the other on the lower level to drain the pipes. Now, disconnect the shut-off valve from the supply tube.

- Use a small bowl, towel, or sponge when removing the fixture shut-off valve to trap the residue water in the pipe.

Step 2: Remove the Old Valve

- Disconnect the mounting nut holding the flexible tube to the outlet nipple on the shut-off valve. Then remove the line from the valve. Using two channel lock pliers, disconnect the compression nut that fits the water supply pipe, grip the valve with one channel lock plier, and turn the compression nut with the other one. Slide the body of the valve on the pipe’s water end, then slide the brass compression nut and ring off the line.

- You can use the compression ring and the nut with the new valve again. However, removing them and installing the new ones that come with the new valve is advisable. Now, remove the compression sleeve. Due to pushing against the pipe, it may have changed its size and, hence, may be difficult to remove. In this case, you’d need to use a tubing cutter to cut the copper back. On the new section of the pipe, fix the new compression valve.

- However, if the compression sleeve appears to be removable but is not budging with pliers, try a compression sleeve puller; it would come in handy.

Step 3: Install the New Valve

- Use a rag to remove the pipe with the old valve, compression nut, and sleeve. Onto the line, slide the new compression nut and the compression sleeve. Make room for the valve by sliding these pieces well down the pipe.

- Onto the water pipe, slide the valve, ensuring that the pipe seats fully into the valve socket. Next, slide the compression nut and the ring up against the valve’s bottom, and then onto the valve’s body, thread the compression nut. Using your hands, tighten the nut as far as it can go. Hold the valve with one pair of pliers and tighten the compression nut with another. To ensure that you’ve fully tightened the nut, use the pair of pliers to turn the compression nut another one-quarter.

- Now, reconnect the flexible water supply line to the opening on the valve. Use your hands to tighten it fully, and then one-quarter turn using pliers.

Step 4: Check for Leaks

- Close the shut-off valve fully, and turn on the water supply on the main shut-off valve. At the fitting of the compression on the valve, check for leaks. Open the new shut-off valve as you continue to look for leaks on both the flex tube and the compression fitting. If you identify any leaking, tighten down the nuts until the leaking stops.

- Sometimes, compression valves can have slow leaks, so checking them a few hours after installation is advisable to ensure no seeping water.

- If you identify any leaks, shut off the water, remove the pipe’s pressure, tighten the compression nut further, and recheck it.

Have you seen how easy it is to install a compression shut-off valve in your pipes? Now roll up your sleeves and get the job done. Good luck, buddy! If you want to know about other types of valves that are used in plumbing systems, then refer to the following link:

The Complete Guide to Various Types of Valves in Plumbing Systems

Image Courtesy: Image 2

Author Bio

Fidelis Kinai – Fidelis Muti possess a bachelor’s in English and Journalism and have over four years of professional experienced writing and proofreading materials for print and online platforms, including newspapers, magazines, websites, blogs, and social media accounts. He also have over three years of experience as a marketing assistant and social media manager.

He is versatile and diligent and will produce exemplary content within time to meet your deadline.

He can deliver most work within 2-3 days; rush orders are accepted whenever possible. He is based in the Kenya but travel often and work for clients all over the world.