The construction industry is implementing many environmentally friendly building practices and thus, traditional materials are making way for newer, more innovative, and eco-friendlier alternatives. The focus of all these innovations is to reduce pollution in some way. In this article, Gharpedia shares some amazing information about pollution absorbing bricks. This green construction material reduces air pollution and promotes a healthy environment for residents.

Here’s a video to sum up all the points mentioned below:

So, let’s start the journey to learn more.

What is a Pollution Absorbing Brick?

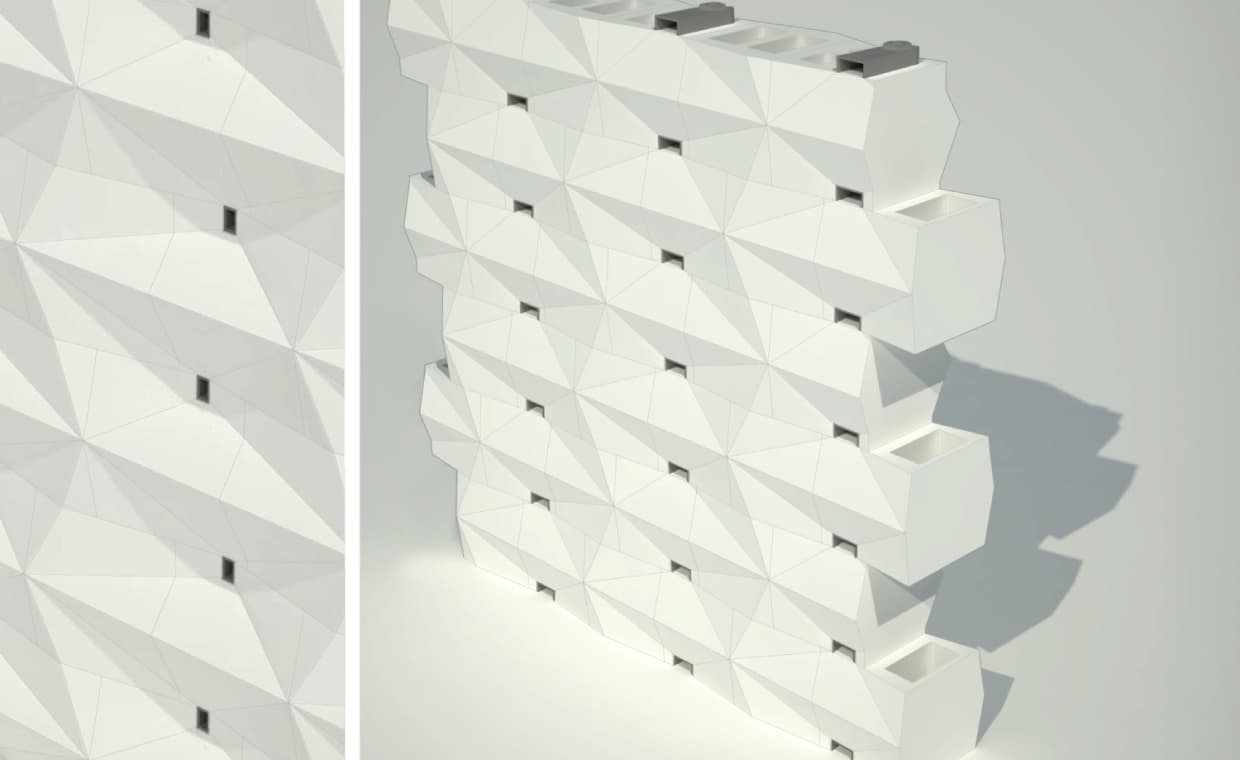

New York City College of Architecture and Environmental Design assistant professor Carmen Trudell has developed a pollution absorbing brick that can remove pollutants from the air and release clean air. This product is also known as a breathe brick. This brick’s ventilation support feature can be used in the construction of buildings. There are two layers of specialised brick on the outside and an insulation layer on the inside of breathe brick, making it a part of a building’s normal ventilation system. Cryo-filtration, an innovation adopted from modern vacuum cleaners, is the heart of breathe brick function.

Manufacturing Process of Breathable Brick

Rather than a traditional brick material, porous concrete is a key pollution absorbing brick material. For this reason, they have a faceted structure to distribute airflow throughout the system better. A coupler made of recycled plastic between two bricks, collects the particles at the bottom of the hopper. The main components of such eco-friendly bricks are concrete and plastic couplers made of recycled plastic. It is possible to manufacture lightweight bricks by replacing sand with expanded polystyrene (EPS). However, these bricks will have various qualities, including strength and absorbency.

The breathe brick consists of four modules that are connected by a coupler. The first module comprises a cyclonic separator and compartment for reinforcement bars. The second module contains a waste tube and reinforcement cavity. This module is close to the first module, and a coupler connects them. The third module includes a cyclonic separator, waste tube, and reinforcement cavity. It is situated on top of the first and second modules.

To ensure proper arrangement, connect the cyclonic separator from the first module with the separator in the third module. The waste tube in the second module and the waste tube in the third module are connected. The fourth module only has a cavity for inserting reinforcement bars. All four modules work together as a purifying unit.

‘Fathima Shirin and Anjana Jayakumar’ mentioned in their research paper titled ‘Breathe Brick’. (Published in the International Research Journal of Engineering and Technology (IRJET)). The brick was tested to determine its filtration capacity. The results showed that it filters 30% of fine particles, like airborne pollutants, and 100% of coarser particles, like dust.

Due to its lack of mechanical components, this system consumed significantly less energy throughout its creation. It’s much less expensive than mechanical air filtration methods in large-scale operations.

Benefits of Pollution Absorbing Brick

The following are some benefits of these eco-friendly bricks:

- This system uses less energy because it doesn’t require any mechanical components.

- When compared to mechanical air filtering systems used in large-scale applications, it is affordable.

- It’s safe for the environment and won’t run out of resources.

- Air-purifying bricks are cost-effective because there is no need for professional labourers to erect them.

- It’s best suited for areas with poor air quality.

- It is possible to reduce air pollution in small communities and developing regions by using this method.

- Using the pollution-absorbing brick system as an active (integrated) or passive (separate) HVAC system is possible, and it can also be a part of an energy-efficient home designs.

- It improves the thermal effect in buildings as it requires low carbon content.

- It is an energy-efficient product as it does not use any electricity and has low embodied energy.

Limitations of Pollution Absorbing Brick

Some limitations of pollution absorbing brick are:

- Using breathe bricks’ passive filtration mechanism, the outer wall can take up to double the original size, reducing the amount of inside space.

- They are suitable only for load-bearing structures with a maximum of two floors.

Applications of Pollution Absorbing Brick

Some applications of air-purifying bricks are as follows:

- For citizens in the United States as well as in underdeveloped countries, leading-edge technology can have a positive impact on their lives. Projects as diverse as employing this microbe-harvesting technology to light LEDs or building toilet blocks for those living in underdeveloped nations can all benefit from the deployment of the air-cleansing brick.

- Further, the breathe brick was shown during the Milan 2015 Expo with a built-in filtering mechanism that collects pollution from the air and stores contaminating particles in a receptacle at the bottom of the device.

How Breathe Brick Works

Pollution absorbing bricks are installed in the structure’s walls as a passive filtering system. On the exterior, there is a pollution absorbing brick wall that blocks pollutants from entering the structure and an interior wall that keeps the facility’s temperature stable. It is coupled with the breathe brick’s filtering system. The brick acts as a cyclone, allowing air from the surrounding area to travel through the filter, separating the pollutants and dust from the clean air.

After that, the filtered air passes through a brick coupler, which is an integral aspect of the system. Made of recycled plastic, it is more of an air outlet. The filtered particles are directed to the hopper by this device. The user must empty and clean the hopper on a frequent basis because of the accumulation of dust. However, because of its enormous size, they don’t have to clean it every day.

The air goes through the chamber and out the opening after filtration. In addition, air enters the structure’s interiors directly through any working outlets or windows. HVAC systems are activated in the event of a malfunctioning door or window.

Conclusion

Pollution is an issue that needs attention and action immediately, and the globe is scrambling to find a remedy. This can be solved with the use of low-emission building materials and green construction materials like pollution absorbing bricks. This method is especially beneficial in areas with high levels of pollution. Small towns and emerging regions can benefit from this method of reducing air pollution while maintaining a healthy environment for residents.

Before you leave the page, you must read our article on eco-bricks:

Eco-bricks: Much-Needed Solution to Plastic Pollution

Image Courtesy: Image 1, Image 2, Image 3, Image 5, Image 6

Author Bio

Nafisa Nazneen Choudhury – Nafisa Nazneen Choudhury is a Civil Engineer (completed B.E. from Assam Engineering College) and is currently pursuing M.Tech in Structural Engineering at National Institute of Technology, Silchar. She is a Technical Content Writer, having over 3 years of experience and has wrote many articles related to Civil Engineering. She is also a Book Author (Authored – “Dream Tales of NNC: Revenge By Murder”) and her book can be found on Amazon. She is also a Guest Author at Gharpedia. Moreover, she is a certified member at Institution of Civil Engineers (ICE) and National Society of Professional Engineers (NSPE). She writes her blogs at her website – nnc2017.wordpress.com. She can be reached on LinkedIn.