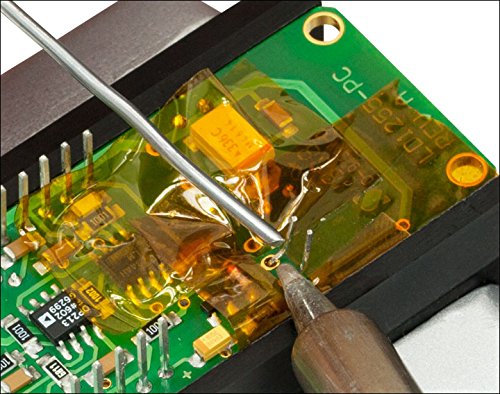

Polyimide tapes are generally used for various industrial applications, as it has numerous benefits. The tapes are highly demanded in various industries such as petroleum, petrochemicals, food and beverage, construction, automotive, electronics, aerospace, and textile. The tapes are also used in electronic printing and fax machines, medical applications, and in many other industries and applications. The polyimide tape is designed for high performance and durability, providing the needed support and thermal insulation to the required application areas. Polyimide Tape can be used for numerous applications, as it is widely used in thermal and pressure applications, and can be used in a wide range of packaging systems such as bags, tubes, panels, wraps, and membranes. Thus, it is a cost-effective option and it is widely used for its superior performance and versatility.

Polyimide Tape is Adhesive!

Polyimide tape applications range from small polyimide masking tape to high performance full-color printed circuit boards. Due to the polyimide’s excellent physical characteristics, the tapes are able to maintain their sticky and non wavy adhesive tapes, even under high-stress environments. The tapes are great solutions for applications where high-performance and long-term stability are important. The polyimide tape’s high optical and electromagnetic properties ensure that the components or installed system are well protected from external interference and other unwanted noise sources.

Polyimide Tape’s Dielectric Strength

Polyimide tape applications are based on Dielectric Strength, which is a property of a material, and its thickness, which define the dielectric strength of a material. It is a multilayer film which possesses a thickness ranging between one and thirty micrometers. The total thickness of the material is measured in inches. The thicknesses are based on numerous factors including dielectric constant, temperature, exposure, and pressure.

Electric Conduction in Polyimide Tape

The dielectric constant, D t, is defined as the ratio of the charge to the conductivity at room temperature. The higher the value, the better the electrical conduction. For polyimide tape applications, the dielectric constant is approximately ten percent, which is considered quite good. Thus, when dealing with electrical equipment that require an enhanced electrical conduction, the thicker the polyimide backing thickness, the better the electrical conduction.

The thinness of the film is based on various factors:

- The first factor is the type of material being used to develop the device or component. The thicker the film, the better the transmission of energy.

- The second factor is the mechanical properties of the device or component being used to develop the electronic equipment or product.

- Thirdly, it is important to consider the coating that is applied on the polyimide masking tape.

The polyimide tape can be made from various materials including, polyimide PVC, polyimide ICP, polyimide ELI, silicone, and the popular polyimide BOP. All of these materials have their own advantages. Polyimide PVC is more flexible than the other polyimide ICP because of its thicker base. These polyimide sheets are also easier to manufacture because they contain a PVC base, which makes them more durable and sturdy. On the other hand, silicone and the other silicone sheets are hard and flexible but produce thicker and more durable film tapes.

The third and final factor to consider is the type of coating that is applied to the polyimide tape. The polyimide tape coating is important because it imparts different attributes and characteristics to the finished product. For example, some polyimide tapes can have gold contacts while others may have silver contacts. Some may have higher thermal conductivity and others may have excellent electrical insulation properties. Thus, it is important to choose the right type of coating when one desires to use the masking tape in a certain application.

The Bottom Line

Using polyimide tape has become a popular method of application for the application of gold, silver, copper, and nickel masks for circuit boards. It is easy to apply, reusable, safe, and has a wide range of applications. Furthermore, the adhesive can be cleaned easily with water and can stand up to heavy-duty activities. Polyimide tape is cost-efficient as well because of its low material cost. Its low cost and superior performance make it the best adhesive for electronic manufacturing.

You may also like to following article: