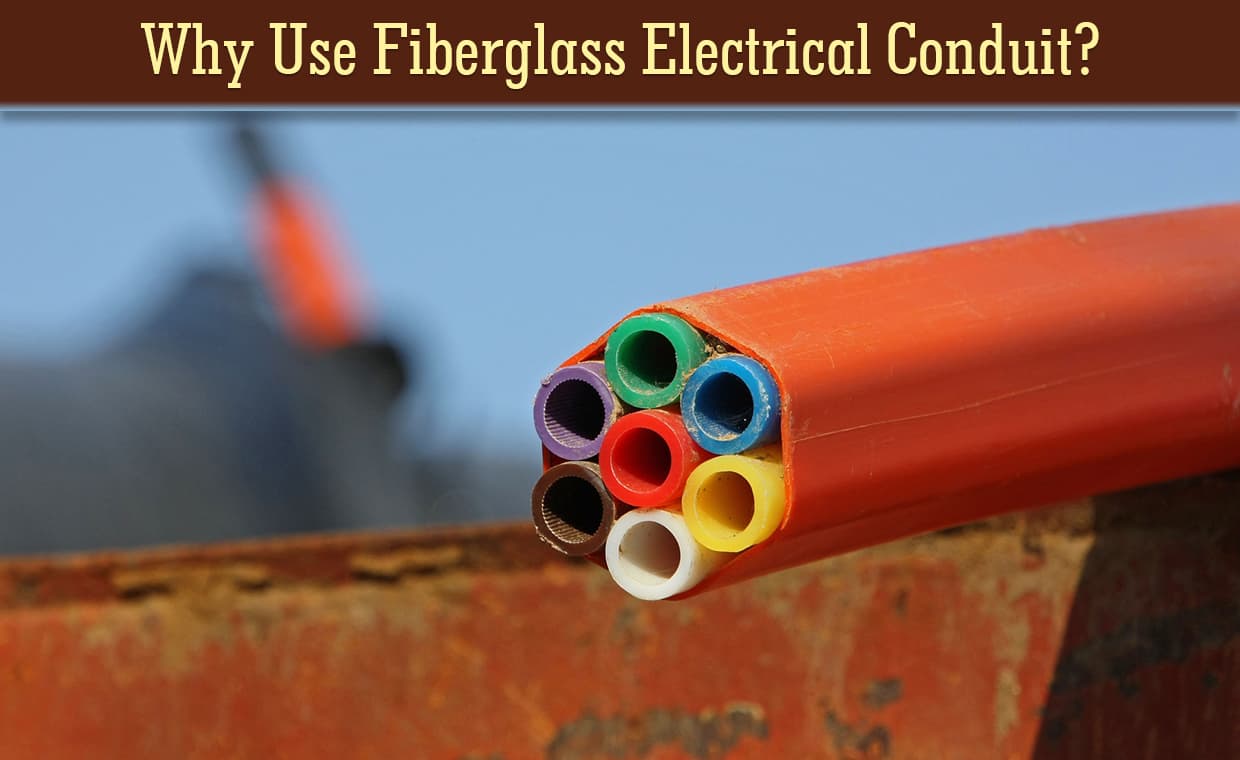

While many builders are now using RTRC conduits and fittings, others are working with engineers to understand exactly what this material is and why it is preferential over other rigid materials. Most often used as electrical conduits, couplings, fittings, and connectors when running cables above or below ground, there are several reasons to use fiberglass instead of such materials as PVC.

To help you understand, we’ll break down some of the most important reasons to use fiberglass conduits or RTRC – Reinforced Thermosetting Resin Conduit in your construction.

Reasons to Use Fiberglass Conduits(RTRC) in Your Construction

RTRC – Reinforced Thermosetting Resin Conduit

In case you think, why use fiberglass conduits in your construction, then the followings are the most convincing reasons to use fiberglass conduits-

01. UV Stable and Corrosion Resistance

02. Safer for the Environment

03. Durable Enclosure for Electrical Wiring

04. Cost-Effective Transport of Materials

Take a detailed look,

01. UV Stable and Corrosion Resistance:

It has been many years since underground cables were run to keep them safe from damage resulting from such things as weather and accidents. However, PVC casings (conduits) were often used, but these were heavier and not as stable as RTRC conduits and couplings. You will find that RTRC for industrial projects from FRE composites is engineered to be UV stable and also extremely resistant to corrosion.

02. Safer for the Environment:

The ultimate benefit from UV stability and corrosion-resistant RTRC conduits is going to be the fact that this makes them the best of all materials for the environment. Also, bear in mind that when an alternative, PVC, is used, there can be a significant impact on the local environment. It has long been known that PVC is manufactured with additives such as lead, phthalates, organotins, and cadmium. As PVC decomposes over time, these toxic additives may leach into the ground and even evaporate into the atmosphere. Most often children are the ones most at risk from the unnecessary dangers associated with PVC.

03. Durable Enclosure for Electrical Wiring:

Any time electrical wiring is exposed, there is always the potential for damage such as corrosion and/or exposure to moisture. This can lead to shorts in the circuitry, which can then lead to a fire. Other things an electric wire can be damaged from are exposure to saline and a number of other chemicals that can lead to the same dangers. According to the National Electrical Code, NEC, there are strict regulations on the types of electrical conduits used in construction and one of the things they must have is protection in environments known to be harsh. Fiberglass electrical conduits (RTRC) are specially developed to meet these strict regulations.

04. Cost-Effective Transport of Materials:

If you compare fiberglass conduit vs PVC, fiberglass conduits are much more stable and safer. For example, it is much lighter in weight. As a result, it will require less fuel to be transported from manufacturer to end-user and this will almost always result in lower costs to the contractor. With the price of gas and diesel skyrocketing, keeping those costs lower can benefit the contractor, thus increasing profitability.

In the final notes, when all is said and done, RTRC fiberglass conduits and couplings are far superior to outdated PVC. If you haven’t already done so, take the time to explore the many benefits of fiberglass and you will see that it is not only safer all the way around but is the most cost-effective product of its type and why more and more building contractors have made the switch.

Image Courtesy: Image 2