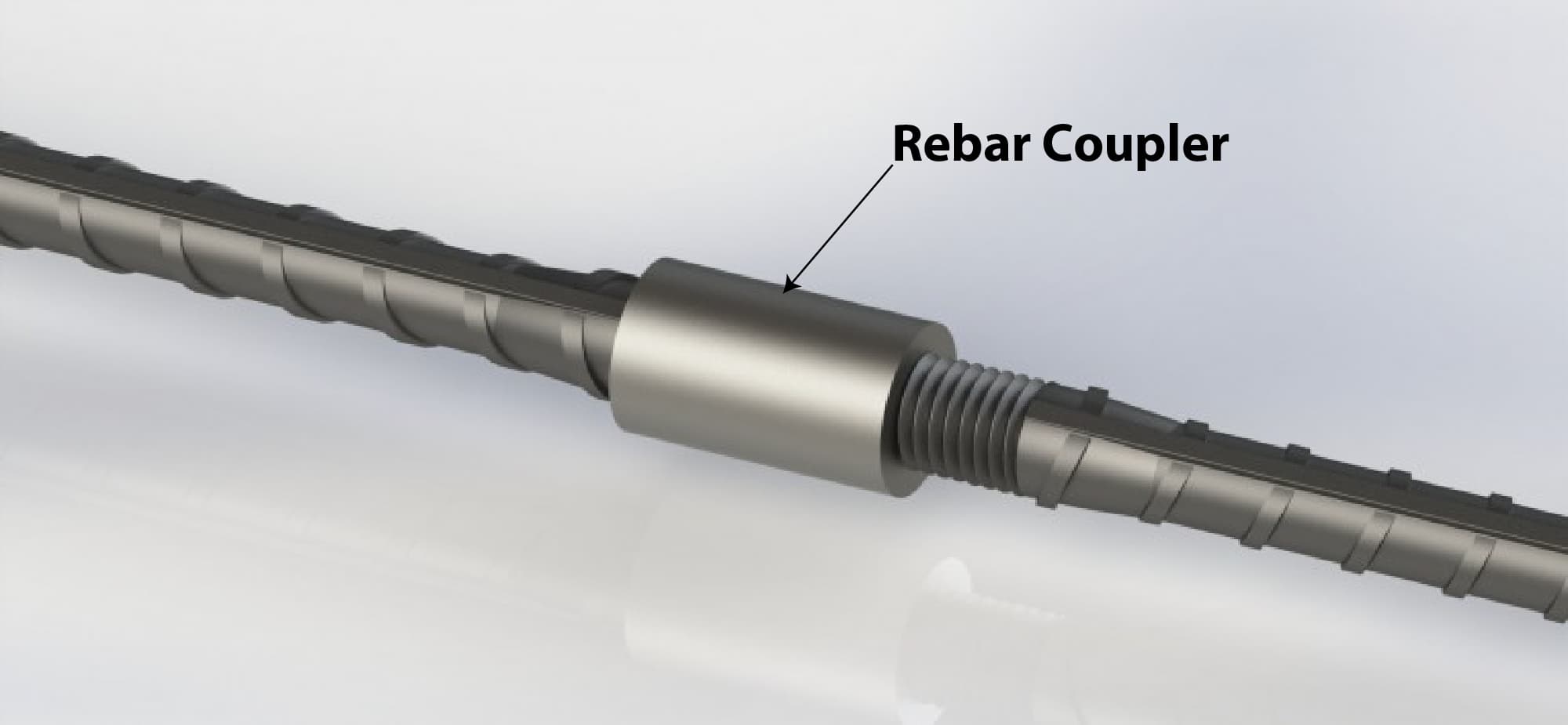

RCC structures uses rebar couplers instead of the old method of overlapping and welding in reinforcement. When long bars are needed, or new bars are added to the end of existing bars, the lapping system is used. In this system, the bars are tied together with wires next to each other. Welding is done the same way as lapping, but instead of tying the bars together with wire, they are joined by welding.

Since the lapping and welding systems waste many bars, a different system called the rebar couplers or the coupler in reinforcement is used. This system connects the two ends of a bar so that it can be used to reinforce a building continuously. The coupler in reinforcement is used because it is economical and saves money. It differs from the lapping system, which wastes some of the bars. The rebar coupler saves much money on large-diameter bars used in big building projects and skyscraper construction. Most of the time, the rebar couplers are also called mechanical splices. The rebar coupler is used in all kinds of construction, like building buildings, bridges, dams, towers, etc.

Types of Rebar Coupler

In reinforcement, there are mainly two types of rebar couplers, such as,

01. Threaded Rebar Coupler

i. Roll Thread Rebar Coupler

A threading machine is used to thread the coupler in a roll thread rebar coupler. The ends of TMT bars are threaded in a Roll Thread Machine so that they can be used with a roll thread coupler in the reinforcement process. The TMT bar is then fitted with a rebar coupler at either end, similar to how nuts and bolts are used in construction, to allow for continuous reinforcing.

ii. Cold Forged Rebar Coupler

Cold Forged Rebar Couplings, like Roll Thread Rebar Couplings, are threaded using a dedicated machine. Instead, the TMT bar’s end is forged using hydraulic pressure in this coupler’s forging machine. TMT bar ends are threaded by a threading machine and then attached to a rebar coupler, after which they undergo a minimal length reduction and thickness increase during the forging process. A cold forged rebar coupler is approved for big government and infrastructure projects. The Indian government has approved this system and was given the BIS code IS: 16172-2014.

02. Non-Threaded Rebar Coupler

i. MBT Rebar Coupler

The primary purpose of the MBT Rebar Coupler is to withstand the extreme stresses imposed by continuous reinforcing. For situations with insufficient bar length for continuous reinforcement and the lap, length is short, this MBT coupler in reinforcement can be employed. In addition to new builds, MBT couplers are used in retrofits. The top MBT coupler has anywhere from 6-8 bolts. MBT couplers tend to be longer than their threaded counterparts. MBT couplers’ durability is determined by the number of bolts used to secure them into place during strengthening.

ii. Crimping Rebar Coupler

Rebar couplers that use crimping were the first used in reinforced concrete construction, followed by couplers that use threading. No thread is used while crimping a rebar coupler. A crimping machine is used to compress the thread less rebar coupler at both ends of the TMT bar.

More resources are expended on the crimping coupler, and the price of labor is high. When used in reinforcement, a crimping coupler is permanent once it has been crimped. For these reasons, the crimping rebar coupler technology has not been successful in the market.

Rebar Coupler Testing Procedures

Rebar coupler testing is used to process coupler in reinforcement. Here are a few examples of rebar coupler tests:

- Cyclic Tensile Test

- Static Tensile Test

- Low Cycle Fatigue Test

- High Cycle Fatigue Test

- Yield Strength of Steel

- Slip Test

- Chemical Test

Advantages of Rebar Coupler

- Because of the importance of compatibility, rebar couplers are made with tensile strengths that exceed those of rebar.

- The coupler for rebar serves the same purpose as continuous reinforcement. Thus, according to BIS456-2000 Cl.26.2.5, splicing does not necessitate staggering the reinforcing bars. Additionally, the rebar’s consistency makes it a great option for grounding electrical current.

- Rebar couplers ease the flow of concrete and aid in compacting the material around the rebar. The optimal size of RCC structural members is achieved through the combination of steel and concrete’s workability.

- Installation times are cut down significantly, and fewer checks for quality are needed when using a rebar coupler, which contributes to greater site productivity.

- A rebar coupler lowers the costs of lapped rebar, binding wires, unused rebar, and skilled labor for bending parts of the rebar. Also, it takes much less time to finish a cycle of threading rebar, and you don’t need automated bending machines. It means that using it saves a lot of money and time

Disadvantages of Rebar Coupler

- There is a chance that the connection between two shafts won’t be straight, putting too much force on the coupling, shaft, and bearing, causing them to wear out faster than they should.

- It’s hard to find rebar couplers on the market with a diameter of 32mm or more.

- If the grade of the rebar couple is not the same as the reinforcement bars, it could cause damage to the building.

- To put things together, you need skilled workers.

Conclusion

A rebar coupler is a technical tool used to make long bar pieces. The main job of this coupler in reinforcement is to connect two TMT bars so that reinforcement can go on in a straight line. The rebar coupler is used in all kinds of construction, like building buildings, bridges, dams, towers, etc.

Rebar couplers can replace rebar sections that bend or buckle in a construction junction. A rebar coupler is required for linking rebar’s that can withstand their full tensional loads. Strings are attached to the ends of the joining bars, and the coupler sleeves used to link them transmit the rebar’s tension throughout the union.

Image Courtesy: Image 1, Image 2, Image 3

Author Bio

Sikandar Choudhury – Sikandar Monwar Huda Choudhury is a freelance article writer who is passionate about sharing his knowledge and experience with others through writing. With several years of experience in the engineering field and having written 100+ articles related to construction, Sikandar is a skilled writer with a talent for breaking down complex concepts and making them accessible to a wider audience. Sikandar is always looking for new opportunities to share his knowledge and experience with others through writing and is available for hire as a freelance civil engineering article writer. He is easily reachable on LinkedIn- https://www.linkedin.com/in/sikandar-monwar-huda-choudhury-2b3a1a20a/.