General practice is to check when the ground and plinth beams are ready for concreting i.e. reinforcement fully tied up but ideal practice would be to check it in two phase i.e.

01. First, check formwork before you allow placing of reinforcement. This is necessary as certain formwork defects can’t be corrected or are difficult to correct after reinforcement is placed in position.

02. Checking reinforcement.

Hence as a standard engineering practice one should check first the formwork before reinforcement placed or tied.

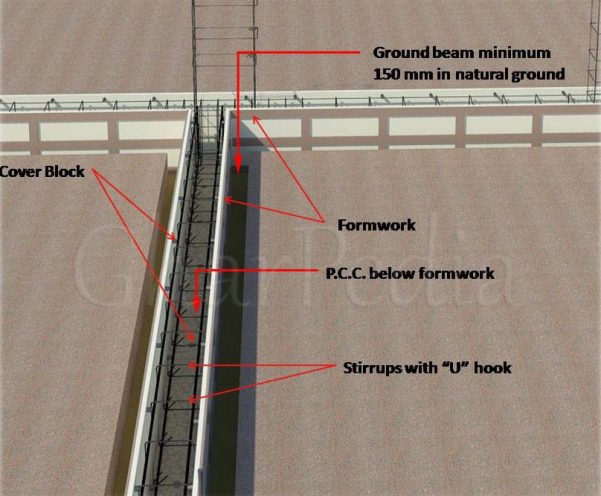

01. Centering and shuttering / Formwork:

- P.C.C. of appropriate grade and thickness (minimum 50 mm and M 5 or 1: 4:8 grade) should be done before starting shuttering for ground beam and it should be properly levelled and in perfect line.

- The P.C.C. shall extended minimum 50 mm beyond the width of beam on both faces. Check all the level of ground beams. It should be min 150 mm in natural ground, so that the earth filled within walls or a beam doesn’t escape during plinth filling. Do it even, not mentioned in drawings. See that all Ground beams are on same level.

- See that all the soil on which beam is laid is properly compacted (particularly in case of freshly excavated foundation pits) to that the ground beam doesn’t sag during curing or watering on account of settlement of loose soil.

- Practice of providing bricks is not recommended as it doesn’t keep in maintaining proper level and line.

- Carryout formwork for ground beams or plinth beams after filling as providing props may result in delay as removal props needs time and as filling work can be taken up during that period resulting in delay of slab.

- The shuttering should be dry and shall be cleaned carefully before applying mould release agent. The same type of release agent should be used throughout on similar shuttering materials.

- The surface of shuttering should be even and thinly coated with mould release agent.

- The mould release agent should not come in contact with reinforcement or the hardened concrete.

- Shuttering should be fixed in such a manner that the joints should be tight against leakage of cement slurry.

- Check the size of beam before tying or placing reinforcement.

- Ensure that at junction of beam column is tight and it shouldn’t bulge during concreting.

- Remove all the debris e.g. dust, paper, leaves, chippings of woods, nails, reinforcement wastage, soil particles etc.

02. Reinforcement:

- Before placing the concrete, Check the reinforcement details with bar bending schedule and get an approval from structural consultant.

- The reinforcement of beam must in proper alignment. If span of beam is more than 6 to 9 meter than camber should be provided as per drawing.

- Check the laps of beam with detailed drawing. Never keep laps in middle of beam if they have long span. Keeps the lap at different location at different location at few different bars.

- Check the joints details as per detailed drawing- flexible or rigid.

- Bent up bars must be as per detailed drawing.

- Always check whenever the reinforcement of cantilever beam is in top doubly anchored.

- Also needs to check the counter balance of cantilever beam.

- Stirrups must be provided at junction of beams and columns which is generally ignored.