Table of Contents

Quick Summary

- Tempered Glass is called Toughened Glass. It is a processed glass appreciated globally for its safety features.

- The glass is manufactured by heating and quickly cooling standard glass.

- When it breaks, it forms small, dull pieces instead of sharp shards.

- It is more durable than regular Glass.

- It can handle heat, pressure, and sudden impact better than normal Glass.

- Used in homes, offices, automobiles, and public areas.

- The surface stays smooth and pristine for a long time.

- The glass is customisable in different colours, patterns, and layers.

- It is easy to clean with an all-purpose cleaner, or mild soapy water and a microfibre cloth.

- Once made, it cannot be reshaped or trimmed.

- Although costlier, tempered glass lasts longer and adds safety and style.

What Is Tempered Glass?

Tempered glass or toughened glass is a distinct class of safety glass trusted across industries for various reasons. Toughened glass properties and applications make it one of the widely used materials in modern construction, interior design, and automotive applications.

The glass is processed through alternating heating and cooling methods to improve its strength and durability. Unlike regular float glass, tempered glass doesn’t break into sharp shards. Instead, it crumbles into small, blunt pieces. This safety feature makes it a safer option in the event of accidents or breakage.

Tempered glass: What Makes It a Safer Choice?

Tempered glass undergoes a thermal tempering process that includes heating the glass to a high temperature (approximately 600–650°C) and then rapidly cooling it.

This treatment impacts the glass in two ways. Firstly, the outer surface undergoes the process of compression, while the inner layers of the glass undergo tension. Finally, the process creates a glass which is superior in quality; stronger, more resilient and less prone to dangerous breakage.

Tempered glass is:

- At least 5-6 times stronger than normal glass.

- Resistant to thermal stress and sudden impact

- Safer when broken, as it shatters into small, blunt pieces..

Due to these benefits, tempered glass is commonly used in places where safety and strength are the priority. Among processed glass types, tempered glass is highly valued for its toughness. Besides toughness, let’s read about tempered glass properties.

Tempered Glass Properties in Outlined Details

1. Higher Strength

The toughness of tempered glass gives it strength. Unlike common glasses, it is neither fragile nor breakage-prone, and it does not crack under pressure.

2. Thermal Resistance

Tempered glass offers greater thermal resistance than normal glass. It can resist the impact of sudden temperature changes. It does not crack or break till a certain temperature. It is a great idea to install tempered glass in homes where heat exposure is common. For instance, in kitchen windows, exterior windows, and other heat-prone areas, tempered glass can make a huge difference.

3. Shatter Resistant

Tempered glass is shatter-resistant, which means the glass does not break like ordinary glass. Even if it breaks, it crumbles into small, blunt pieces.

These rounded pieces are comparatively harmless and generally do not cause severe cuts and injuries, making them a safer option for homes. These features also make it an ideal choice for public places and spaces meant for kids.

4. Surface Durability

Tempered glass offers strong surface durability. The glass can easily resist scratches from daily use. Temperature variations too have minimal impact on it. The surface remains smooth for years with minimal maintenance and resists chipping easily. Tempered glass is tougher than regular glass. It can combat pressure impacts with almost zero effect, making it ideal for heavy-duty applications and high-traffic areas.

5. Outstanding Clarity and Aesthetics

Tempered glass is a combination of strength, transparency, and visual appeal. It offers natural clarity, durability and a wide scope for customisation. However, once manufactured, its appearance and properties cannot be changed. During the manufacturing process, tempered glass can be tinted, frosted, patterned or printed.

The glass can also be layered with other glasses and a PVB interlayer to create laminated glass. The scope of customisation enhances its aesthetic value and functional utility.

Manufacturing Process of the Tempered Glass

The manufacturing process of the tempered glass is the key factor behind its resilient nature. The variation of the glass is induced during the manufacturing process because once the glass is made, it cannot be modified.

The manufacturing process of tempered glass is divided into three interrelated phases.

- Regular glass sheets are selected, shaped, and cut to the required size. The process requires clean and pristine glass for tempering, as impurities can lead to breakage.

- The prepared glass sheet is then heated in a specialised furnace to temperatures exceeding 1100°F (650°C).

- The red-hot glass sheet is then exposed to intense blasts of cold air. This rapid cooling causes the outer layer of glass to solidify much faster than the inner layer.

As the inner layer of the tempered glass cools, it contracts and pulls on the hardened, solid outer layer. This tugging force generates areas of compression and tension between the outside and inside of the glass pane. The balance between the compressed outer surface and the overstretched inner core gives tempered glass its signature durability and resilience.

The heating and rapid cooling convert a delicate glass into an ultra-protective solid material. To see how this process works visually, watch this detailed video on tempered glass

Edge Treatment and Finishing Options for Tempered Glass

Tempered glass edges can be finished in multiple ways. Each finish enhances safety and looks and also ensures the glass fits better within its frame or design.

1. Flat Polish

A flat polish produces smooth, straight edges on a tempered glass sheet, creating a clean and modern look. The process removes sharpness and makes edges safe to touch.

2. Bevelled Edge

Bevelled edges have a slanted surface along the perimeter. The edging treatment adds depth and a decorative effect. It is common in mirrors and decorative glass panels.

3. Pencil Polish

A pencil polish creates a smooth, rounded edge, with a curved pencil-like profile. This finish works well for tabletops and shelves.

4. Chamfered Edge

Chamfered edges have an angled cut between the top and side surfaces. This treatment softens the corners without creating a full bevel. It also reduces chipping risks.

5. Seamed Edge

Seamed edges are lightly sanded to remove sharpness while retaining tempered glass’s natural look. This option is used for glass that will be hidden within frames.

6. Mitered Edge

Mitered edges of tempered glass are cut at precise angles, usually at 45 degrees. These glasses are used when two glass panels meet at one corner. This finish creates a neat and seamless joint line.

Proper edge treatment of tempered glass improves both safety and style. The choice, however, depends on design needs, function, and budget.

General Application of Tempered Glass

The strength and the durability of tempered glass are its USP, making it a preferred choice in various settings like residential, commercial and office spaces. Let’s explore how it is used in different environments.

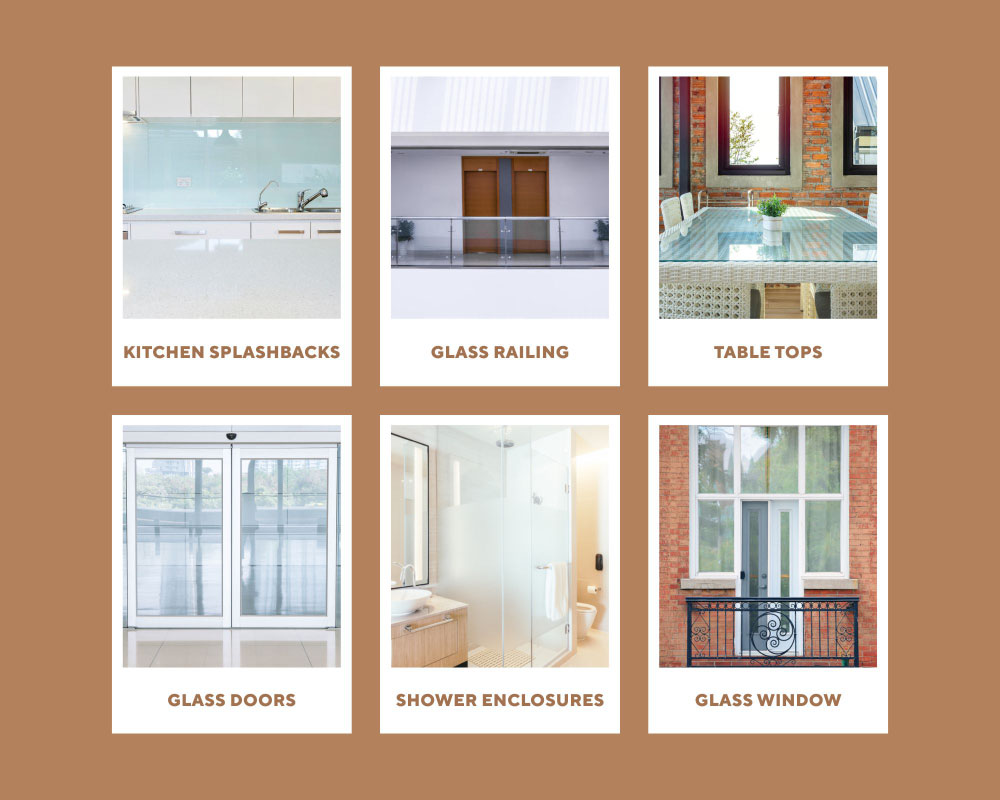

1. Residential Use

- Shower enclosures and bath panels

- Balcony railings and windows

- Kitchen splashbacks

- Table tops, glass shelves, and doors

Tampered glass integrates a modern and sleek look to homes while offering several practical benefits that facilitate better safety and security.

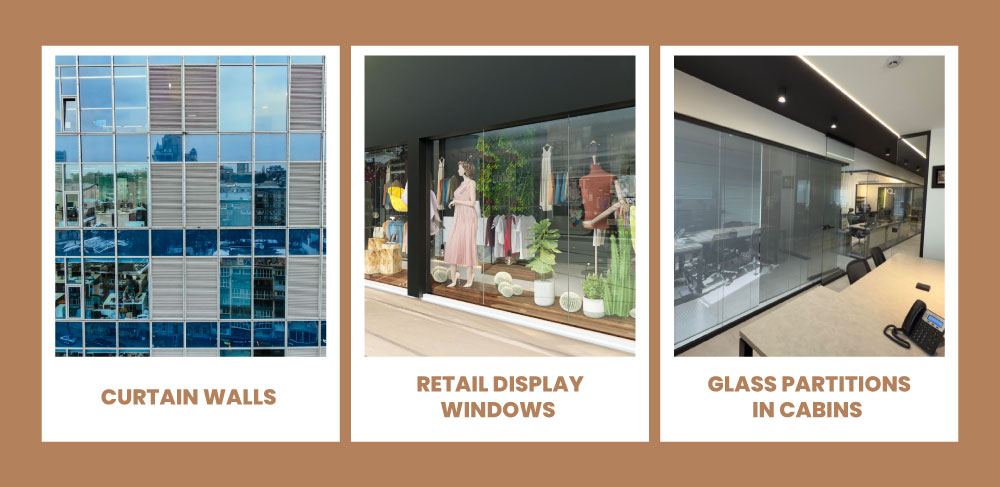

1. Commercial and Office Spaces

- Glass partitions in cabins and meeting rooms

- Shopfronts and retail display windows

- Building facades and curtain walls

In commercial buildings, it combines design and safety, especially in high-traffic areas. Beyond residential and office spaces, tempered glass is widely used in the automotive industry, public areas with heavy foot traffic, and in some specific industrial sectors. For example, tempered glass is used in solar panels, greenhouse glass, laboratory panels, machinery guards, and safety enclosures.

Its properties include the ability to withstand heat, pressure, and chemical impacts. These multiple features make this processed glass one of the most reliable and beneficial options in the glass category. For more insights on tempered glass features and uses, refer to this detailed guide.

The Benefits of Using Tempered Glass

The properties of the tempered glass are the foundation of its many benefits. Let’s summarise the benefits of tempered glass here.

- Enhanced safety – Tempered glass carries a low risk of injury due to its unique break pattern. It shatters into small, blunt pieces and not sharp shards.

- Durability – The surface durability of tempered glass creates a higher resistance to physical and thermal shock; hence, it is a better choice for home/office installations.

- Aesthetic Appeal – The sleek look of the glass complements both the modern and retro styles of the home decor.

- Low Maintenance – Easy to clean, it can be maintained with an all-purpose cleaner or simply with soapy water and a sponge/microfibre cloth.

- Environmentally Friendly – Tempered glass is 100 per cent recyclable and eco-friendly, supporting sustainable practices.

- Reduced Carbon Footprint – Tempered glass needs less material, lasts longer, improves insulation, reduces energy consumption, and is fully recyclable, making it an excellent choice for sustainable construction.

- Complies With Safety Standards – Installation of this glass must meet relevant building codes and safety standards. Tempered glass adheres to the international safety standard and the Green Building Certification standard criterion

The Limitations of the Tempered Glass

Tempered glass offers multiple advantages; however, it has a few limitations. It is better to count the limitations before installation.

- Once the tempering process is complete, the glass cannot be modified by size, tint, or shape.

- It is expensive compared to normal glass.

- It cannot be repaired if broken. You have to replace it.

How Much Does Tempered Glass Cost?

- Tempered glass price ranges from ₹200 to ₹800 per sq. ft., as the price varies with quality.

- Thicker glass costs more than thinner glass.

- Larger sizes of tempered glass increase the overall price.

- Custom shapes or edge finishes obviously add to the cost of the glass.

- Special coatings or tints raise the price of tempered glass.

- Compared to laminated glass, tempered glass is usually cheaper.

- However, the glass variant is costlier than standard toughened glass, but it offers greater strength and safety, making the higher price a worthwhile deal.

Also Read:

Types of Glass Available in Market & their Architectural Features!

Maintenance Tips: How To Maintain Tempered Glass?

Although robust and almost impact-free, tempered glass lasts longer with little care and maintenance.

1. Cleaning Care:

- Use mild soap with water or an all-purpose cleaner.

- Avoid strong chemicals or rough pads for cleaning the glass.

- Use a microfiber cloth to wipe dry to avoid water stains on the glass.

2. Additional tips:

- Check metal frames or the seals regularly.

- Do not apply pressure to the glass corners.

- Do not hit the glass with hard objects.

3. Popular Myths about Tempered Glass

- Myth: Tempered glass is unbreakable.

- Fact: It’s much stronger but not indestructible.

- Myth: All safety glasses are tempered.

- Fact: Laminated and wired glass are also safety glasses.

- Myth: Scratches mean it’s not tempered.

- Fact: Surface scratches do not actually indicate the poor strength of the glass.

Conclusion

Tempered glass is more than just strong. It is a modern solution that combines safety, style, and security in the glass-covered areas of your home. The glass possesses a unique ability to withstand heat, pressure, and impact, which makes it ideal for residences, commercial premises, vehicles, and public areas. Toughened glass properties and applications highlight its durability, safety features, and versatility across multiple industries.

Although the upfront cost is higher than a regular glass, the long-term benefits and consistent performance of tempered glass make it worth purchasing.

Whether you are constructing a new building or updating your interiors, installing tempered glass offers the perfect balance of safety and style for your space.

Also Read:Clear Glass vs Tempered Glass: Know the Better Choice

FAQs On Tempered Glass Properties

1. How to Determine If a Glass is Tempered Glass?

First of all, you should check for a stamp which reads ‘tempered glass’ on one of the corners of the glass. Authentic glass manufacturers mark tempered glass to validate its authenticity. Furthermore, you can check the glass surface with polarised lenses. An original tempered glass will display a distinctive strain pattern under the polarised light, which a regular glass fails to display.

2. What Are the Safety Standards for Tempered Glass?

Specifically, it is recommended to install tempered glass in windows that are less than 18 inches from the floor, within 36 inches horizontally of a door, and larger than 9 square feet in area. Staircases, railings, and balconies should be protected with tempered glass if there are any glass installation options available. It will prevent the risk of accidents due to glass breakage.

3. Is Tempered Glass Fireproof?

Standard window glass will shatter at approximately 250 degrees Fahrenheit (F). In comparison, tempered glass can withstand temperatures up to approximately 500 degrees Fahrenheit. Fire-resistant glass, on the other hand, can typically survive heat over 1600 degrees F.

4. Is Tempered Glass Water Resistant?

Yes, tempered glass is water-resistant by nature. That is why tempered glass is counted as a trusted choice for glass kitchen splashbacks, where a high level of humidity is a common issue. Tempered glass is used for glass bathroom work surfaces where severe temperatures are often a potential issue.

References

Saddam Hussain, P.s Chen (2022) in Experimental Report on Compression Loading Test of Tempered Glass Panels [Online] available from https://www.researchgate.net/publication/371509471_Experimental_Report_on_Compression_Loading_Test_of_Tempered_Glass_Panels

Feifei Cheng (2013) in Using Building Codes and Standards to Improve Construction Quality and Safety DOI:10.1061/9780784413135.010, in Conference: International Conference on Construction and Real Estate Management 2013[online] Available from https://www.researchgate.net/publication/269057327_Using_Building_Codes_and_Standards_to_Improve_Construction_Quality_and_Safety