The glass is a magical material as it can be formed or moulded into any shape. Traditionally, it used to be used for vessels like bowls, vases, bottles, jars and drinking glasses. It is also used for paperweights, marbles, and beads. Nowadays glass has more decorative use and it becomes the first choice of architect and interior designers. The glass is manufactured in various ways like blowing, casting, drawing, pressing, rolling, and spinning.

Bending, cutting & grinding, opaque marking and silvering are the common glass treatments which are given to change the function and to improve the quality of surface finish.

Common Types of Glass Treatments:

Following are the common types of glass treatments:

Glass Bending:

Glass bending is one kind of process in which, rods, sheets or tubes of glasses are bent into the desired shape by placing them in temperature controlled special ovens. They are heated to suitable temperature then they are taken out and bent into the desired shape.

DIY Glass Bending Step By Step:

- Take rods, tubes or sheet of glass, clamp it to a ring stand.

- Keep a container of water or a fire extinguisher nearby.

- Turn a Bunsen burner on medium or high.

- Lower the glass slowly into the flame.

- Rotate the glass slowly and constantly near the flame.

- Bend the hot glass around the heat-proof object or use the heat-proof tool to bend the object.

- Reduce airflow to the burner.

- Hold the bend over the flame for two or three minutes.

- Let the glass cool.

Glass Cutting and Grinding:

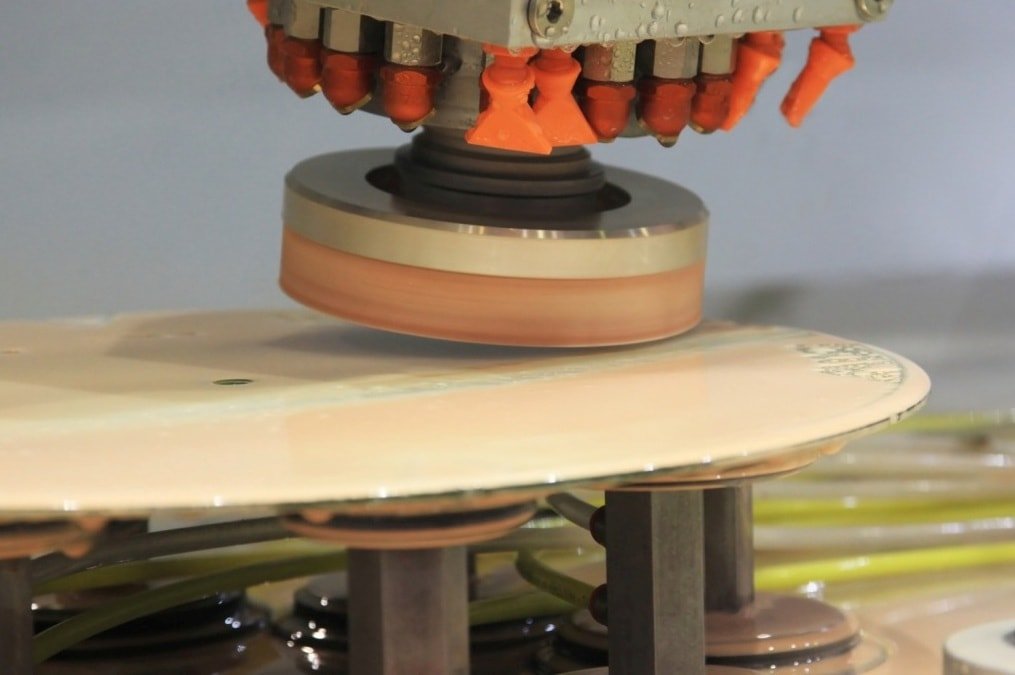

The glass is cut in required size and shape with the help of either a diamond cutter or rough glass or small wheels of hardened steel. Glass Cutting is done mechanically or manually. The glass cutting is also done by laser based technology. There are many other technologies like water jet and diamond dicing, etc.

Glass Cutting

The mechanical method of glass cutting required following preciseness.

- Cutting force

- Cutting Wheel Diameter

- Cutting Wheel Angle

- Cutting Speed

- Cutting fluids and others

DIY Glass Cutting by Manual Method:

- Take a sheet of glass and draw the scribe line at where you want to cut the glass. The scribe line is a formation of micro crack at the cutting path with the help of steel glass cutter tool. The micro crack weakens the glass along the cutting path.

- To separate the glass, give stressed and little pressure to the glass at the scribe line.

Which Points Indicates Poor Glass Cutting?

- Failure of edge once the glass is installed in its final application

- Breakage in the quenching process, when tempering glass

- Surface scratches

- Seaming belts and grinding wheels wear more quickly

- Inferior edge quality

- Decreased edge strength

- Increased rework

Above points increase the cost of construction, reduce the productivity and increase the maintenance of machinery.

The edges of the glass can be rounded by using the suitable grinding stone, or grinding wheels. Grinding edges of the glass are done for safety, cosmetics, functionality, cleanliness, enhanced dimensional tolerance, and to prevent chipping. It is also used to remove the sharp or raw edge of the cut glass.

Grinding Edges of Glass

Glass Opaque making or Glass Etching:

Normally, glass is transparent. It can be made opaque mechanically by grinding the surface by emery. The surface of the glass can also be made opaque chemically by the application of hydrofluoric acid. It is also known as glass etching.

Glass Silvering:

Glass silvering consists of applying a very thin coat of tin on the surface of the glass. The silver is deposited on this layer of tin. The silvered surface is protected against the atmospheric effects by applying a suitable paint over it. Fire polishing is also a way to glass treatment. It is called as hydropox flame treatment. To achieve a speed and quality, there are two more technology premixed and post mixed based on oxygen and hydrogen.

Market Forms of Glass:

Following are the market forms or commercial forms of Glass:

- Sheet Glass

- Plate Glass

- Glass Block

- Float Glass

- Frosted Glass

- Foam Glass

- Fiber Glass

- Wired Glass or Reinforced Glass

- Insulating Glass

- Heat Strengthened Glass

- Heat absorbing Glass and Glare Reducing Glass

- Laminated Glass

- Safety Glass

- Bullet Resisting Glass

- Shielding Glass

- Patterned Glass

- Structural Glass

- Perforated Glass

- Soluble Glass

- Ultra Violet Ray Glass

- Corrugated Glass

Also Read:

What is Glass & How it is Made?

What is the Manufacturing Process of Glass?