The flexibility of concrete makes it suitable for various purposes. However, there are many drawbacks associated with it as well i.e. poor tensile strength; corrosion of reinforcement, and vulnerable to chemical attacks, affecting its durability etc. The recent development in construction technology has led to production of such concretes which have nearly overcome these limitations and are close to ideal conditions. Some of the techniques which enhance its properties include modifying microstructure of cement paste, inducing more air so that it becomes light weight, enabling flexibility in reducing or increasing setting rate, etc.

What is Understood by Special Concrete?

The word “Special” itself has significance and here it depicts the unique features associated with the concrete. The word ‘special’ suggests that the concrete is even more strong, durable and tougher. To make the special concrete, special ingredients are added through a special process as per the requirement.

A technology is employed to enhance its particular properties which are beneficial for specific type of works, say for example – in case of buildings where lightweight concrete is preferred for roofs so that cost saving is achieved and also the aesthetical aspect is kept intact keeping into consideration the surrounding.

Types & Properties of Special Concrete

Let us understand the various types of special concrete –

Lightweight Concrete:

Usually conventional concrete has high density and high thermal conductivity. But the same is not in case of lightweight concrete. In case of lightweight concrete, the density is reduced to as low as 35% compared to traditional concrete. This reduction in weight is achieved by entraining large quantities of air, using no-fines concrete and lightweight aggregates. Lightweight aggregates as well as the voids in concrete helps in reducing the overall weight.

According to ‘A. M. Neville’ (Author of Concrete Technology), because of air-filled voids, lightweight concrete provides good thermal insulation and has a satisfactory durability but is not highly resistant to abrasion. In general, lightweight concrete is more expensive than ordinary concrete, and mixing, handling and placing require more care and attention than ordinary concrete. However, for many purposes the advantages of lightweight concrete outweigh its disadvantages, and there is a continuing world-wide trend towards more lightweight concrete in applications such as prestressed concrete, High-rise buildings and even shell roofs.

Ultra-Lightweight Concrete:

Such type of concrete has density within the range of 600 to 1000 kg/m3. It is made up of cement, sand and polystyrene beads of expanded nature having 6 mm diameter. It is manufactured by the process of polymerisation which involves dispersing in aqueous medium a liquid styrene and also a polymerization catalyst.

Vacuum Concrete:

Excess water and air are removed with the help of suction in such type of concrete. The duration for treatment depends upon water-cement ratio and the amount of water to be removed. However, it is more effective when the water cement ratio is below 0.4. Here, the pressure of suction is one-third of the atmospheric pressure. Vibration of concrete before the process of vacuum can help the whole process of manufacturing.

Mass Concrete:

In such type of concrete, large sized aggregates of low slump are used to lower the quantity of cement in the concrete mix. This makes the mixture hard and dry which leads to, use of high power vibrators of immersion category for compaction. It is generally placed in open forms. Because of the higher mass, it may lead to the rise in temperature of concrete which can be lowered by allowing cold water or ice use during concrete mixing.

DID YOU KNOW! – ICE IS ADDED IN THE CONCRETE MIX WHILE CONCRETING IN HOT WEATHER. Click on the link below to know more:

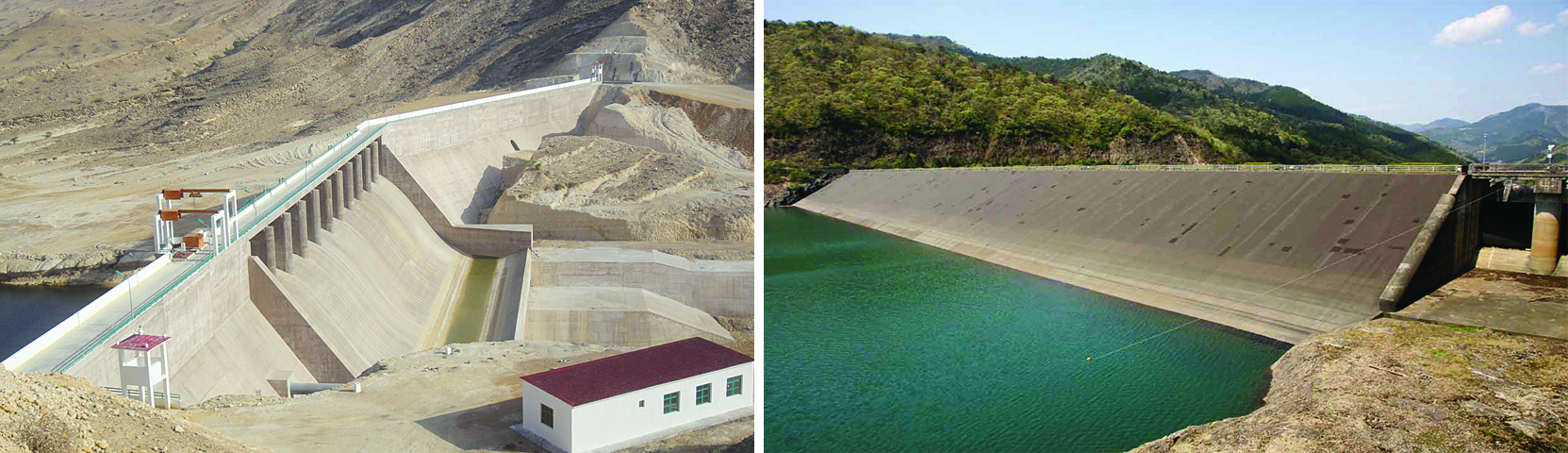

Roller Compacted Concrete:

Roller Compacted Concrete is a type of concrete consisting of mixture of cement, aggregates, water and in some cases, water reducing mixtures. This makes the mixture stiff and the mix develops the consistency of damp gravel. Such concrete needs to be placed continuously since the water content is low in it. The concrete also needs modified asphalt paver and roller for compaction. It has strength and characteristics of a conventional concrete.

According to ‘M. S. Shetty’ (Author of Concrete Technology Theory and Practice), roller compacted concrete is placed in layers thin enough to allow complete compaction. The optimum layer thickness ranges from 20 to 30 cm. To ensure adequate bonding between the new and old layer or at cold joint, segregation must be prevented and a high plasticity bedding mix must be used at the start of the placement. A compressive strength of about 7 MPa to 30 MPa must be obtained. For effective consolidation, roller compacted concrete must be dry enough to support the mass of the vibrating equipment, and adequately wet to allow the cement paste to be evenly distributed throughout the mass during mixing and consolidation process.

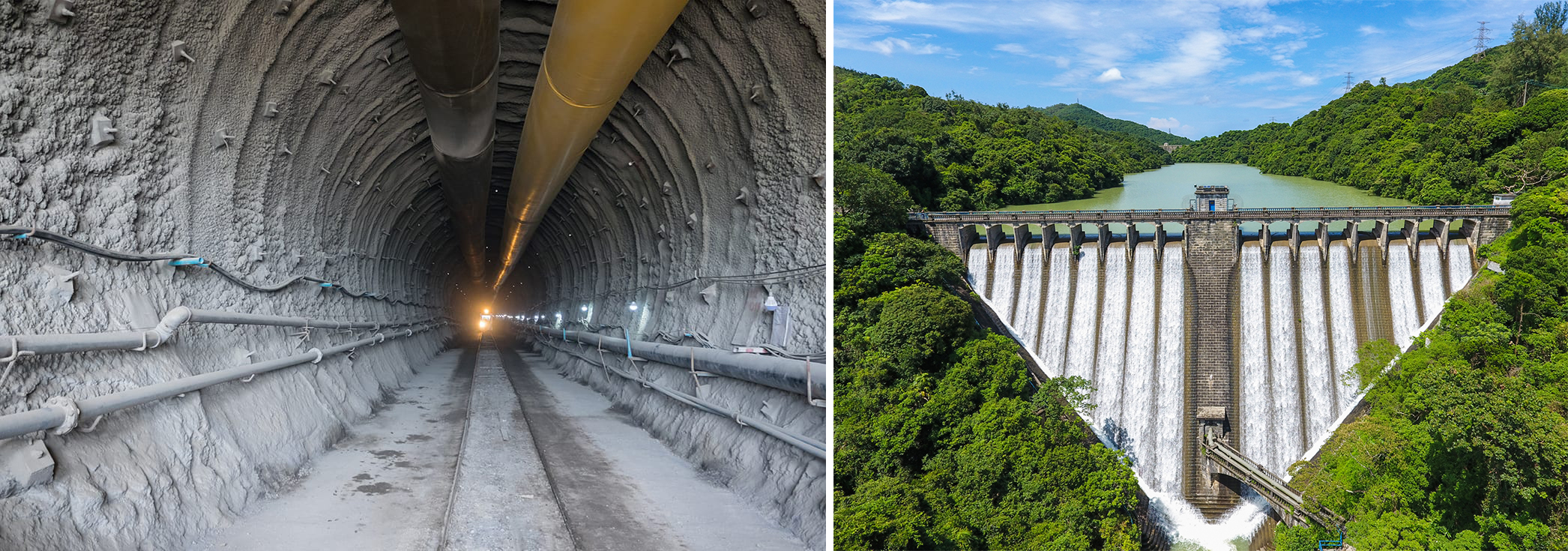

Shotcrete:

It is a very fine concrete or mortar which is laid out by jetting mechanism at high velocity on to a prepared surface. Shotcrete is also known by various other names like Blowcrete, Guniting, Guncrete, Jet-crete, Nutcrete, etc.

Fibre-Reinforced Concrete:

Normal concrete has many micro-cracks. Such micro-cracks can be removed by inducing fibres in the mix. These fibres help in transferring the loads making it stronger than normal concrete. It also increases impact resisting capacity of the concrete. In simple words, it is a conventional concrete infused with fibres. Fibres can be synthetic or natural depending upon its requirement.

If you want to understand basic of fibre reinforced concrete, do have a glance at this blog of Gharpedia.

Nuclear Concrete:

Nuclear concrete is used for effective radiation shielding. Sometimes additional ingredients like colemanite, boron glass and borocalcite are added into it for improving neutron attenuation properties of concrete.

Uses of Special Concrete

Some of the uses of special concrete are:

- Nuclear concrete is used in radioactive areas as it is capable of absorbing radiation. Apart from that, it acts as a shield to prevent the radiation from spreading outside and causing any harm to human life.

- Fibre reinforced concrete such as Steel Fibre Reinforced Concrete (SFRC) is used in highway and airfield pavements as it has high flexural strength which reduces the thickness of the pavement and the resistance to impact of repeated loading thereby maintaining the strength.

- Shotcrete has wide applications in curved surfaces where laying concrete is difficult by conventional methods. It is applied in vertical surfaces, tunnel lining, reservoirs, swimming pools etc. Its high temperature resisting property makes it suitable for using in chimneys, furnaces, refractories, etc.

- Roller compacted concrete can be sized and shaped easily and hence they are suitable for using in gravity dams and earthen dams considering less requirement of labour.

- Mass concrete is used in dams, canal locks, bridges, retaining walls, maritime structures, bridge abutments, etc.

- Vacuum concrete is used in finishing of floor and stripping of wall forms. It is also used in factories that are involved in production of precast plain and reinforced concrete units.

- Ultra-lightweight concrete is mainly used for manufacturing hollow and solid bricks, lightweight sandwiched panels and sub-base in highway constructions. As it has high thermal insulation efficiency, there are still many more purposes for which it is used.

- Lightweight concrete is used in the partition walls of buildings, in-situ composite roof slabs and floors slabs, load bearing masonry walls, floor panels, etc.

Advantages of Special Concrete

Some of the advantages of special concrete are –

- Ingredients which are normally infused with conventional concrete are easily available.

- It can be remoulded to any shape like the conventional concrete keeping its unique properties intact.

- Special concrete makes the structure more durable as compared to normal concrete since special conditions are maintained in preparing such concrete.

- Special concretes are suitable for extreme weathers and can withstand harsh environmental conditions.

- Low heat characteristics are observed in special concretes. Even temperature controlling is facilitated in such concretes.

- Setting time can be altered in such concretes by changing the ingredients which is not possible in case of normal concrete where each concrete type has a definite setting time based on mix design.

- Special concretes can protect the reinforcements from corrosion.

- Some special concretes have excellent thermal properties which makes them suitable for cold climatic conditions.

Are they Needed in House Constructions?

As a matter of fact, yes, they are widely used in residential buildings. Special concretes like lightweight and ultra-lightweight concretes are used as partitions or in floor panels as they enhance beauty of the surrounding as well as reduce the dead weight of the buildings. Shotcrete is used for those spots and areas of the houses which are difficult to reach for concreting through conventional methods. Lightweight concrete is another type which can be used in load bearing walls to reduce dead weight. Apart from these, translucent concrete is a type of fibre reinforced concrete which is used in residential construction because of its light emitting property which reduces the use of artificial lights and facilitates more natural light thereby reducing cost of lighting for all the times.

Out of all the above, nuclear concrete is not used for residential purpose, as it is not essential to have such higher strength in residential homes. Mass concrete is one more type which is not much used in residential construction as it has excellent strength which makes it better suitable to be used as abutments in bridges rather than homes.

Cost Benefit Analysis of Special Concrete

Fibre reinforced concrete when used in the form of translucent concrete has high initial cost. As they are not economical, they are not much preferred for use. However, some companies have come up with a solution. If fibre reinforced concrete is made from naturally available fibres which are cheap in price then economic construction can be thought of. Further, air entrained concrete requires less raw materials for construction but the process is comparatively costly than the conventional concrete. It mainly depends upon the application and purpose. In a nutshell it can be said that it is cost effective in the long run as maintenance is low and less labour is required for its application. However, because of its high initial cost, special concrete might not be preferred by ordinary families as they would probably prefer repairing the conventional concrete rather than using special concrete though durable.

Conclusion

Special concretes are slowly gaining attention in construction industry because of their unique properties. However, as the mechanism is expensive, lot of research needs to be done for its wider application. In developed countries special concretes are widely used as cost is not a major factor. However as far as underdeveloped and developing countries are concerned, it is a major factor. In large industries they are widely used as durability is their major concern rather than economy. Apart from these, it is wise to use special types of concrete as it has modified properties overcoming the weaknesses of traditional concrete. Such structures will be a boon in earthquake prone areas. The houses can also be safer with special concretes due to enhancement of properties.

Must Read:

Plum Concrete: What | Why | Uses | Design Specifications!

Polymer Concrete: Its Pros-Cons, Uses & Properties

Bioconcrete: New Perspective of Self-Healing Concrete

Image Courtesy: Image 4 – pinterest, Image 5 – pinterest, Image 6 – pinterest, Image 7 – pinterest, Image 8 – pinterest, Image 9 – pinterest, Image 12, Image 13, Image 14(a), Image 14(b), Image 15, Image 16, Image 17, Image 18, Image 20

Author Bio

Nafisa Nazneen Choudhury – Nafisa Nazneen Choudhury is a Civil Engineer (completed B.E. from Assam Engineering College) and is currently pursuing M.Tech in Structural Engineering at National Institute of Technology, Silchar. She is a Technical Content Writer, having over 3 years of experience and has wrote many articles related to Civil Engineering. She is also a Book Author (Authored – “Dream Tales of NNC: Revenge By Murder”) and her book can be found on Amazon. She is also a Guest Author at Gharpedia. Moreover, she is a certified member at Institution of Civil Engineers (ICE) and National Society of Professional Engineers (NSPE). She writes her blogs at her website – nnc2017.wordpress.com. She can be reached on LinkedIn.