Ultrasonic Testing is one of the non-destructive test method based on the transmission of the ultrasonic pulse in the component or materials like concrete, steel, etc. Ultrasonic testing is known as UT or Ultrasonic Pulse Velocity Test or UPV Test. The ultrasonic testing method is based on the use of equipment composed of transducers which produce and receive the ultrasonic wave of 0.01 to 60 MHz. The pulse (wave) depends on the density and the elastic properties of the materials of RCC structure.

Ultrasonic Testing for Concrete

Courtesy - RK Infra Techno

Here is the procedure of ultrasonic testing and general guidelines for assessing the quality of concrete based on the results. It also provides you information about the identification of corrosion prone locations depending on the results of ultrasonic testing and rebound hammer test.

The Procedure of Ultrasonic Testing for the Compressive Strength of Concrete:

Ultrasonic testing consists of measuring the travel time of an ultrasonic pulse or wave of 25 to 60 kHz. The ultrasonic pulse or wave is produced and received by an electro-acoustical transducer. The transducer is held in contact with one surface of the concrete member and receiving the same by a similar transducer in contact with the surface at the other end.

The speed of the pulse or wave is the function of the density of the material. It allows the estimation of the porosity and the detection of discontinuities like cracks in the house. Once the distance between two probes (path length) and time of travel is known, it is possible to determine the average pulse velocity by the following equation.

Pulse velocity= Distance between the two probes (Path Length)/ Time of travel

The higher pulse velocity indicates higher elastic modulus, density and integrity of the concrete.

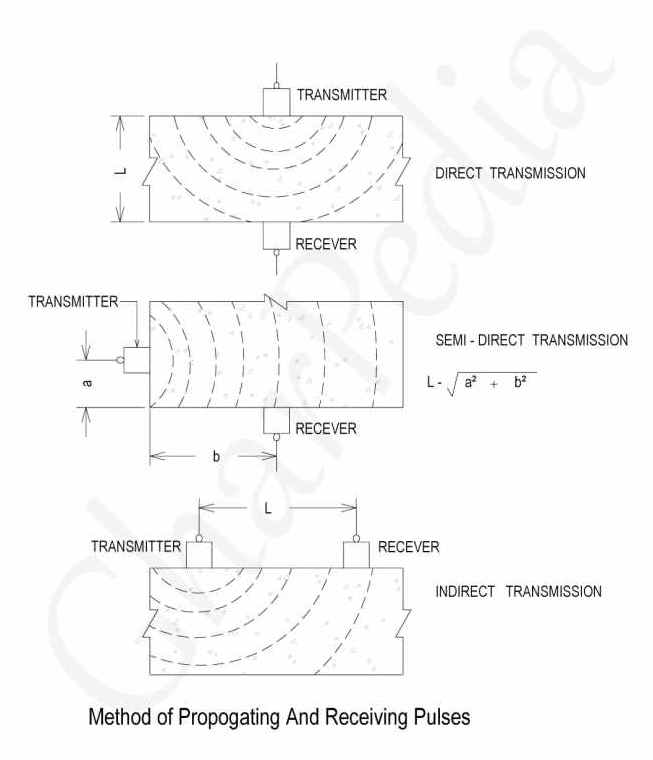

Pulse velocity also depends on the method of propagation and the arrangement of transducers. There are three primary ways in which the transducers may be arranged.

Arrangement of Transducers in Ultrasonic Testing

01. Opposite Faces (Direct Transmission):

If one transducer is placed at one end, and the other one is placed exactly at the opposite end, it is the direct method.

02. Adjacent Faces (Semi-Direct Transmission):

In this method, both transducers are placed on the same surface of the concrete. The receiver receives the ultrasonic pulse coming after striking the molecules of the concrete.

03. Same Face (Indirect Transmission):

It is mostly used for corners of the concrete members.

The maximum pulse energy is transmitted at right angles to the face of the transmitter. The direct transmission method is considered to be the most reliable way.

The Relation between Pulse Velocity of Ultrasonic Testing and the Compressive Strength of Concrete:

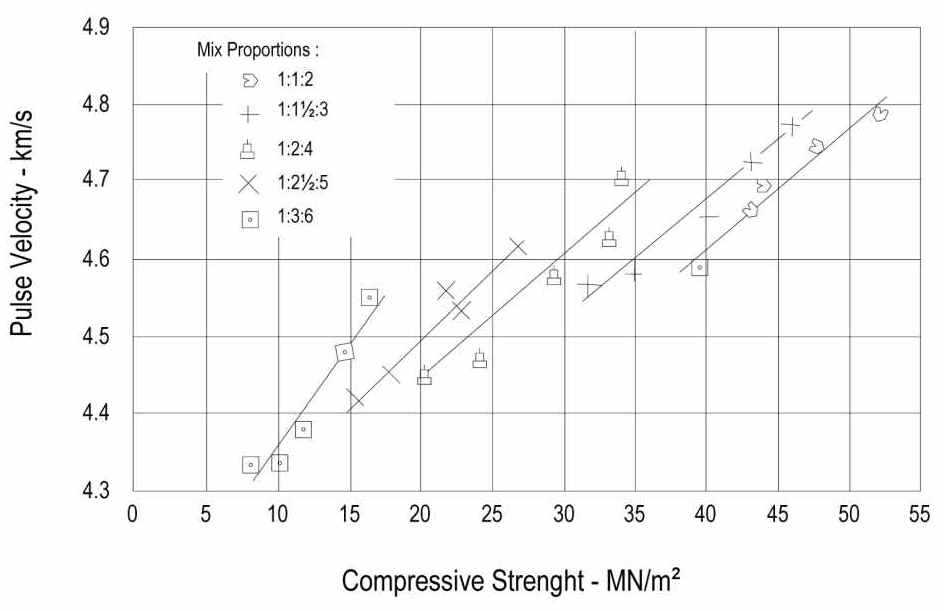

The pulse velocity basically does not directly measure compressive strength. The compressive strength of concrete is influenced by many variables. It is influenced by the types of aggregates, age, moisture content, and mix proportion of concrete. It is also influenced by curing of concrete and others factors. The factors affecting the compressive strength have an influence on the pulse velocity. As a result, a statistical study is essential to relate the pulse velocity and the compressive strength.

Bad concrete (which has been poorly compacted concrete or, there is segregation of materials, internal cracking, or flaws) has the lower pulse velocity although the same materials and mix proportions are used. Good concrete has high pulse velocity thought the materials and mix proportions may be same.

Estimation of the concrete strength can be done by establishing the suitable correlation between the pulse velocity and the compressive strength of concrete specimen made with same mix proportions of materials and in same environmental conditions similar to that of the structure.

Ultrasonic Testing Graph shows the correlation between the pulse velocity and the compressive strength of the concrete.

Ultrasonic Testing Graph

The estimated strength may differ from the actual by 20 percent or more. The correlation so obtained may not be applicable for concrete of another grade or made with different types of materials.

General Guidelines for Concrete Quality based on the UPV Test Results:

| Pulse Velocity in Concrete (Km/Sec) | Concrete Quality (Grade) |

| > 4.0 | Very Good to Excellent |

| 3.5 – 4.0 | Good to Very Good, Slight Porosity may Exist. |

| 3.0 – 3.5 | Satisfactory but Loss of Integrity is Suspected |

| < 3.0 | Poor and Loss of Integrity Exist |

The table shows the qualitative assessment of concrete based on UPV test result.

The Realistic Assessment of the Condition of Concrete Surface:

The realistic assessment of the condition of the concrete surface can be done by the combination of the results of UPV test and rebound hammer test.

Following table identifies the location of corrosion in concrete by combining the results of ultrasonic testing and rebound numbers (rebound Index).

Readings Interpretations of Ultrasonic Testing & Rebound Hammer Testing | Identification of Location According to Readings Interpretations |

|

|

|

|

|

|

|

|

Conclusion:

If the ultrasonic testing shows satisfactory or poor concrete, it indicates that the strength of concrete is not as per the mix design. Therefore two inferences can be drawn:

- The original concrete itself was not having the designed strength due to any reason whatsoever.

- If the records prove that original strength was as per the designed strength, then there is a loss of strength due to various reasons. Thus strengthening, or rehabilitation is needed depending upon loss of strength, the age of the structure, the importance of structure, future life, the extent of strength increase required, etc.

Therefore first carry out non-destructive concrete tests like rebound hammer test which is suggestive of comparatively stronger and weaker areas. The doubtful areas than can be tested with ultrasonic testing or with the combination of tests. The core test would become a must where even the ultrasonic testing suggests poor concrete.