Rebound hammer test is the most appropriate and useful testing methods for comparing the relatively weaker and stronger areas of concrete. The rational use of the various available methods, as well as a possible combination of more than one method, can be particularly interesting from the viewpoint of the validity of results. Rebound hammer devices give a measure of the only surface hardness of the concrete, and then the relationship to any other property of the concrete is empirical.

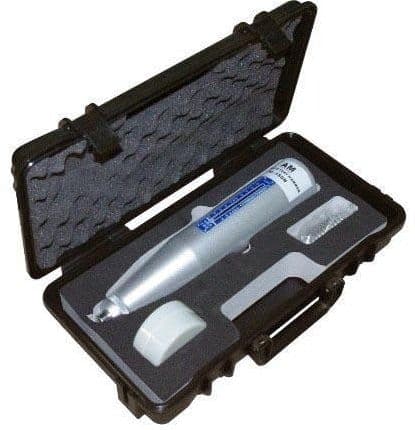

Rebound Hammer Test Devices

We have already discussed the rebound hammer test procedure. We have also discussed points which affect rebound hammer test results. Here we discuss uses of rebound hammer test and its limitations.

Uses Of Rebound Hammer Test:

- It is used to investigate concrete hardness. Hardness measurements provide only the information on the quality of the surface layer of the concrete only.

- It is low cost and has a simple operating procedure.

- The rebound hammer can be used for the concrete surface which is at the horizontal, vertical or intermediate angle. Care should be taken that the hammer should be provided perpendicular to the surface under test.

- It is easy to use because the rebound hammer is light in weight, compact and can be easily carried in hand anywhere.

- It is used to test in-situ concrete as well as fresh concrete after final set. It is used to assess the in-place uniformity of the concrete.

- It is used to find out the exact location of poor quality and deteriorated concrete.

- Rebound hammer test is used to estimate in-place strength if a correlation is developed.

Limitations of Rebound Hammer Test:

01. The Smoothness of the Surface:

Rebound hammer has to be used against smooth and formed surface. It is not applicable for the open textured surface, i.e. a trowelled surface. It should be rubbed smooth with an emery stone.

02. Size, Shape and Rigidity of the Specimen:

If the concrete does not form part of a large mass, any movement caused by the impact of the hammer will result in a reduction in the rebound index or number. In such cases, the member has to be rigidly held or backed up by a heavy mass.

03. Age of the Specimen:

For equal strengths, higher rebound number are obtained with a 7-day old concrete than with a 28-day old.

Rebound hammer test should not be carried out on low strength concrete at early ages. When the concrete strength is less than 7 N/mm2, the concrete surface could be damaged by the hammer.

04. Surface and Internal Moisture Condition of Concrete:

The rebound number is lower for well cured dried specimens than for the same specimen tested after being soaked in water. Therefore, whenever the actual moisture condition of the field concrete is unknown, the surface should be pre-saturated for several hours before testing.

A correlation curve for tests performed on saturated dried concrete specimens should then be used to estimate the compressive strength.

05. Type of Coarse Aggregate:

Though the same type of coarse aggregate is used in the concrete mix, the correlation curves can be different if the sources of the aggregate are different.

06. Type of Cement:

Cement with higher alumina content can have a 100 percent higher compressive strength than with OPC.

Cement with super sulphated content can have a compressive strength 50 percent lower than OPC.

Hence, type of cement may also influence the rebound number.

07. Carbonation of the Concrete Surface:

In older concrete, the carbonation depth can be several millimetres thick. In such cases, the rebound numbers can be up to 50% higher than those obtained on an un-carbonated concrete surface.

Rebound hammer test evaluates surface hardness and in no way gives the exact compressive strength. The surface hardness would depend and vary based on the point it is being held. If it is held where there is the loose concrete matrix, the hardness would be low, and if held over reinforcement bar the hardness would be more. Hence it is not conclusive, but it will guide to carry out the further costly test like UPV test and core test, etc.

Must Read:

Non-Destructive Test of Concrete

Ultrasonic Pulse Velocity Test