Table of Contents

Quick Overview

Here is the quick overview of the difference between one-way slab and two-way slab:

- Explains the difference between a one-way and two-way slab.

- Covers their basic differences such as load transfer, bending directions, reinforcement, span, and thickness.

- Discover the differences and pros and cons of both slab types.

- Explore the design types of one-way and two-way slabs.

In a structural system, the slab forms the floor system, which resists gravity loads (dead loads and live loads) acting on it and transmits them to the vertical framing system, such as columns. Slabs are frequently used as floors and roofs in buildings, bridges decks, the top and bottom of tanks, slabs on grade (grade slab), staircases, and more.

The floor or roof slabs and footings account for the maximum volume of concrete in a structure. Hence, even a slight reduction in design depth (as per codal provision) can lead to considerable economic savings.

In practice, the choice between a one-way slab and a two-way slab for a particular structure largely depends on economy, buildability, loading conditions, and span length.

Let’s dive deeper into the difference between one-way and two-way slab.

Difference Between One-Way and Two-Way Slab

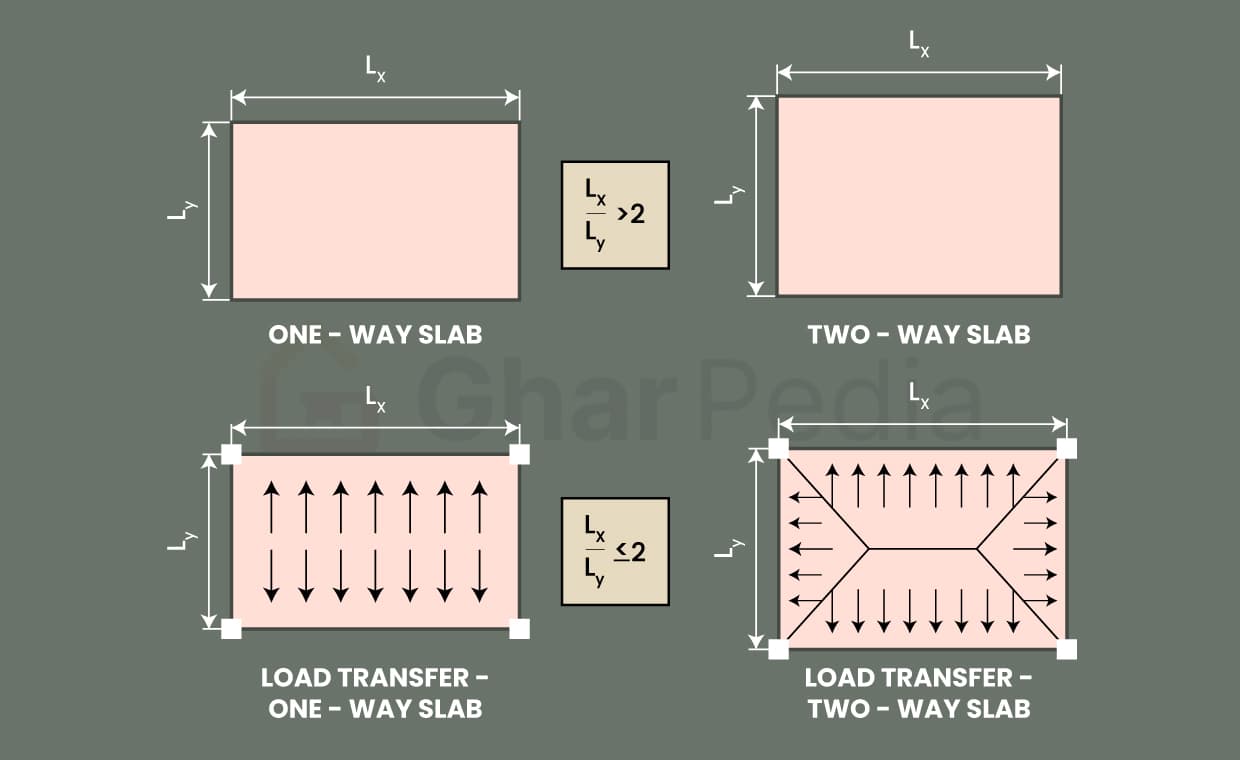

1. Load Transfer

One-Way Slab: A one-way slab bends only in one direction (the spanning direction) and while it transfers the loads to the two opposite supporting walls or beams.

Two-Way Slab: A two-way slab bends in both directions while transferring the loads to all supporting walls or beams, forming a dish or a saucer-like shape.

2. Length-to-Breath Ratio

One-Way Slab: Supported by parallel walls or beams, whose length-to-breadth ratio is equal to or greater than two.

(Length > 2 (Breadth))

Two-Way Slab: Generally supported on all sides (or even three sides), with a length-to-breadth ratio less than two.

(Length < 2 (Breadth))

3. Bending Direction

One-Way Slab: Designed for bending in the spanning direction alone.

Two-Way Slab: Designed for bending in both directions.

4. Reinforcement

One-Way Slab: The main tension reinforcing bars run parallel to the shorter span and are placed at the bottom of the slab. In the transverse direction, a minimum amount distribution steel is provided to resist temperature and shrinkage effects in that direction.

The corner reinforcement or torsional reinforcement is provided at the discontinuous edge of the one-way slab.

Two-Way Slab: In two-way slabs, the main bars are provided in both directions, and they are perpendicular to each other.

The corner reinforcement or torsional reinforcement is provided at the discontinuous edge of the two-way slab.

5. Thickness

One-Way Slab: As per Indian Standard Code IS 456:2000, the thickness of a one-way slab varies between 100mm to 150mm based on the deflection consideration and span.

Two-Way Slab: According to the Indian Standard Code IS 456:2000, generally the thickness of two-way slabs is in the range of 100mm to 200mm, depending upon span and deflection consideration.

6. Span Length

One-Way Slab: The one-way slab may be economical up to a span of 3.6m.

Two-Way Slab: A two-way slab may be economical for panel sizes up to 6m x 6m.

7. Design Types

One-Way Slab: There are mainly three types of designs for a one-way slab.

1. One-way Solid Slab with Beams

2. One-way Ribbed Slab with Beams

3. One-way Ribbed Slab with Integral Beams

Other slabs, like ribbed slab (with joist beams) made of the precast double-tee section and ribbed slab with hollow-block or hollow-cored slab can be designed by assuming the one-way slab action.

Two-Way Slab: There are mainly three types of designs for Two-way slab.

1. Two-way Solid Slab with Beams

2. Two-way Waffle Slab with Beams

3. Two-way Waffle Slab with Integral Beams

Other slabs like two-way slab with the hollow block, waffle slab (with joist beams) made of the precast double-tee section, waffle floor with hollow-block or hollow-cored slabs, two-way flat plates slab, two-way flat slabs, and two-way waffle flat slab can be designed by assuming two-way slab action.

8. Advantages

One-Way Slab:

- It is cheaper to construct than a two-way slab.

- It required less steel reinforcement.

- It is easy to design, and detail, reducing the chances of errors and saving time.

- Due to the greater depth slab, it provides structural strength in the shortest direction.

Two-Way Slab:

- It is ideal for large rooms, halls, and commercial buildings where uniform load distribution is required.

- Two-way slabs can handle heavier loads and longer spans as compared to one-way slabs, often with less deflection.

- As the reinforcement in both directions, it will help to minimise cracks and enhances durability.

- It is economical for panel sizes up to 6m x 6m.

9. Disadvantages

One-Way Slab:

- In a one-way slab, bending occurs only in one direction, which can limit the load distribution.

- It Increases the slab thickness due to less steel reinforcement.

Two-Way Slab:

- The design method of a two-way slab is complex than a one-way slab.

- It requires skilled workers to construct.

- The cost of construction is higher for a two-way slab as compared to a one-way slab.

Common Mistakes to Avoid

Ignoring edge support leads to cracks in one-way slabs and incorrect reinforcement detailing in corners of two-way slabs. Some of the common mistakes you need to avoid during slab construction are improper bar alignment or spacing, inadequate curing, early removal of formwork and use of low-grade or improperly mixed concrete.

Conclusion

Hope this content on the differences between one-way and two-way slabs is helpful to you. The choice will depend largely on the specific requirements of your project, such as the span length, load capacity, and aesthetics.

Also Read: Difference Between Flat Slab & Conventional Slab-Beam System

FAQs on One-Way vs Two-Way Slabs

1. Which Slab is Cost-Effective for Homes, One-way or Two-way?

Generally, one-way slabs are more cost-effective for homes because of the lower reinforcement and simple construction.

2. What are the Key Materials Used in Both Slab Systems?

Both slabs required reinforced concrete (RC), steel bars (TMT or mild steel), and high-grade cement mixtures.

3. What Influences the Choice Between One-Way and Two-Way Slabs?

The choice depends on certain factors like slab dimensions, load requirements, and the overall geometry of the structure.