Table of Contents

Quick Summary

This article highlights how selecting the maximum size of aggregate in concrete can significantly improve quality and economy.

- Explains the role and importance of aggregates in concrete.

- Discusses aggregate gradation and its impact on density and strength.

- Compares uniformly graded and well graded aggregates.

- Covers how larger aggregates reduce cement and water requirements.

- Lists practical factors limiting maximum aggregate size.

- References IS 456 guidelines for choosing appropriate aggregate size.

- Emphasises benefits like reduced shrinkage, cost savings, and improved durability.

When it comes to concrete construction, aggregate is an integral part of it. The aggregate is important as it acts as the structural filler in the concrete. Basically, the aggregates consist of crushed or uncrushed gravels or stones which is derived from the natural sources like river terraces, riverbeds, glacial deposits or rocks and boulders. In order to save the natural resources, in present times the use of artificial aggregates is increasing day by day.

Aggregates are widely used in the construction of concrete houses and for various other concrete structures. Even a small quantity of poor aggregates eventually will end up being the poor-quality aggregates. With the usage of such poor quality aggregates, probably in the initial stage during the service life of the house/building, the structure will invite repairs. Thus, using good quality aggregates is a pre-requisite. Among the various quality criteria like strength, size, gradation is one of the most important criteria of the aggregates. In this article, we shall be particularly discussing about it.

Aggregate Gradation

Aggregate gradation is a process in which the constituents are evenly distributed according to their shape & size that helps the concrete to achieve a maximum density. To achieve the dense mix of concrete, all the ingredients need to be distributed properly in the mix. The mix must have minimum voids so that the concrete can have a compact homogeneous structure. Thus, the size of aggregates along with aggregate gradation is a very important factor while preparing concrete. This factor being important is certainly considered by the concrete experts while they do concrete mix design in the laboratory.

You very well know that the quality of concrete depends upon various factors. Apart from the uniformly graded or distributed aggregates, the use of maximum sized aggregates also affects the quality and strength of the concrete.

According to “Ismaeel H. Musa Albarwary, Lawend Askar & Ziyad N. Aldoski” (Author of Journal Effect of the Aggregate Maximum Size upon Compressive Strength of Concrete), there is an ability to produce economical mixes by producing normal concrete of same strength as rich concrete by selecting a suitable maximum aggregate size.

The particle size distribution of an aggregate is determined by the Sieve analysis. The proper grading of aggregates produces a denser concrete. Therefore, it is essential that fine and coarse aggregates are well graded.

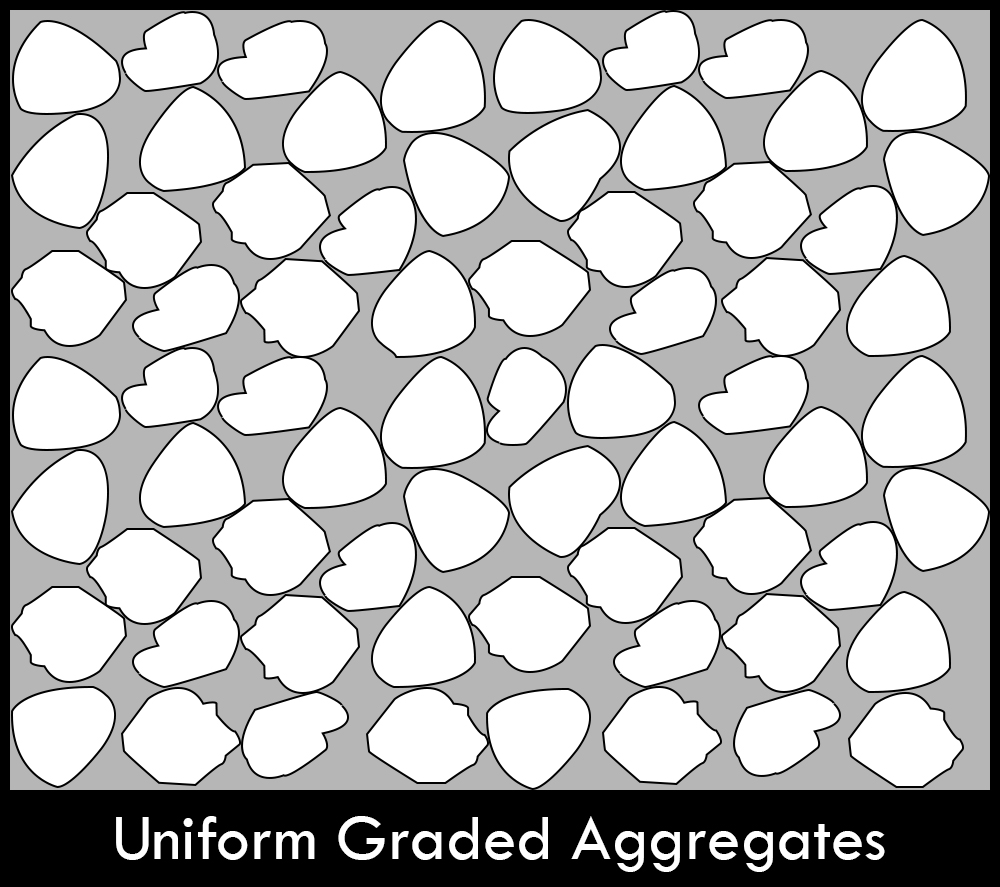

Uniformly Graded Aggregates

In uniformly graded aggregate, all the particles of an aggregate are of uniform size or approximately of same size. Here the compacted mass contains more voids and thus to fill up those voids, more quantity of fine aggregates and cement paste is required.

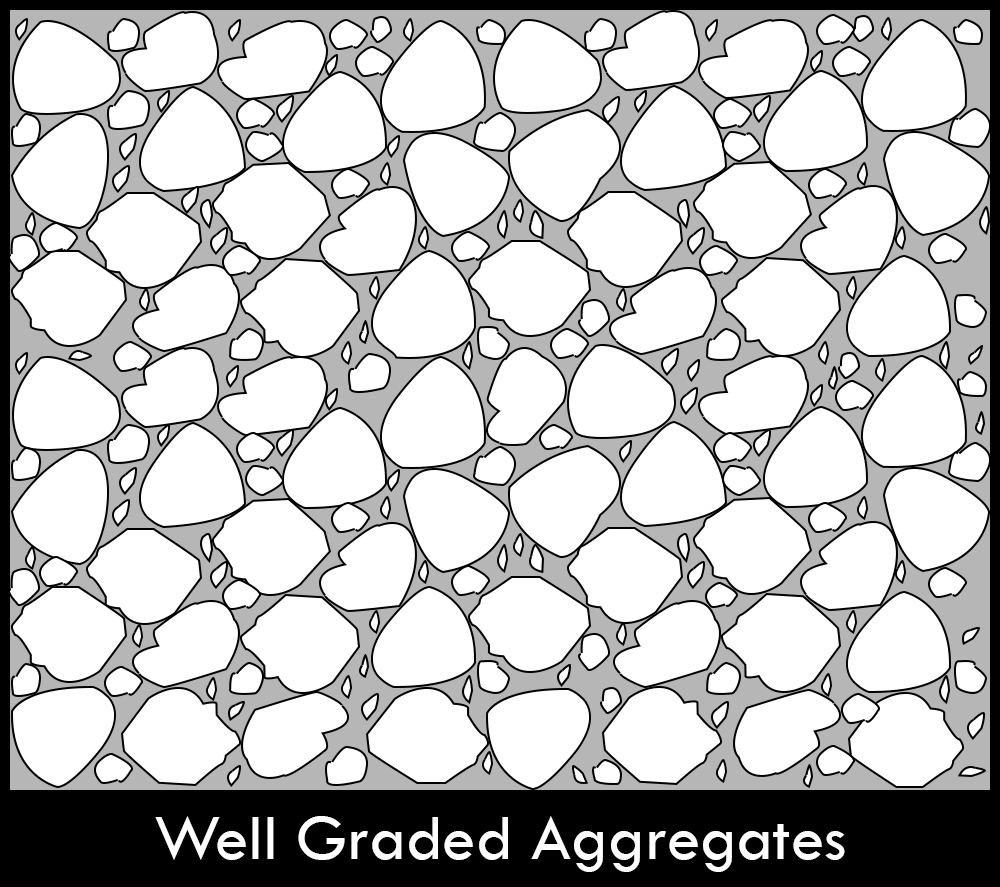

Well Graded Aggregates

A well graded aggregate consists of particles which have a broad range of sizes. Aggregate should be such that the smaller particles should fill the voids between the larger particles. As a result, the compacted mass will contain less voids and need less quantity of fine aggregates and cement paste.

Also Read: Shape Wise Classification of Aggregate

Use of Maximum Sized Aggregates in Concrete

Size of aggregate depends mainly on three factors – type of the structure, size of the structural member and nature of the work. Large sized aggregates have less total surface area hence; less water is required to achieve good workability. Thus, you require less quantity of water to make a workable paste of cement mortar or concrete. You know that the lower water cement ratio can lead to the higher strength of concrete. To have in-depth information regarding the same, please refer our article – Importance of water cement ratio in concrete.

Hence, maximum sized aggregates result in higher strength of concrete that ultimately boost the life of structure.

Benefits of Using the Maximum Size of Aggregates in Concrete

Using the maximum size of aggregates not only increases the service life of a house or a building, but it also procures the following benefits:

01. Reduction of the cement content that is used to make concrete and thereby saving cost.

02. Reduction in water requirement

03. Reduction of drying shrinkage

04. Reduction of void content

However, using maximum size of aggregate in any given condition may be restricted by the following conditions:

01. Thickness of the section, such as beam, lintel, column, shear walls, i.e. too thin sections.

02. Spacing of reinforcement in the entire structural element i.e. distance between two bars.

03. Clear cover in slabs, beams, columns, footings.

04. Mixing, handling and placing techniques of concrete.

Summing Up

As per IS – 456 (Bureau of Indian Standard), the maximum size of aggregates generally used in concrete, can be as large as possible within the specified limit. However, in any case, it should not be greater than ¼ of the minimum thickness of the structural member.

Usually, aggregates having a maximum size of 20 mm are generally considered satisfactory for reinforced concrete work in normal residential works.

Must Read: Why Aggregate has an Important Role in Concrete

FAQs: Maximum Size of Aggregate in Concrete

01. What is the maximum size of aggregate used in concrete?

Usually, aggregates up to 20 mm are used for reinforced concrete in residential structures.

02. How does aggregate size affect concrete strength?

Larger aggregates reduce water demand, leading to a lower water-cement ratio and higher strength.

03. What are the advantages of using larger aggregates?

They lower cement and water consumption, minimise shrinkage, and increase concrete durability.

04. Can large aggregates be used in all types of concrete?

No, their use is limited by factors like section thickness, reinforcement spacing, and cover.

05. What is the difference between well graded and uniformly graded aggregates?

Well graded aggregates have a mix of particle sizes that reduce voids, while uniformly graded ones consist of similar-sized particles, increasing void content.