Since the concept of house was born, walls and roofs have been the basic and most important demands of a house. Originally, stones were used and subsequently bricks came in to use. With the advent of cement, both stone and brick masonry went out of use or are going out of use as the preparation of mortar and for curing of mortar, we need to use water to a great extent. Hence, the name – wet walls. Drywall therefore is a wall of any material which does not use water in any form during its construction. This is important because water is becoming scarce day by day and we need to conserve it by bidding fall well to water intensive technologies, crops etc.

History of Drywall

The U.S. Gypsum Company (USG) invented drywall System in 1916. It was originally called “Sackett Board,” after the Sackett plaster company, a USG subsidiary. The material was first sold in the form of small, fireproof tiles, but within few years, it was sold in multi-layer gypsum and paper sheets. In less than a decade, it took the form what we know today, consisting of a single layer of compressed gypsum sandwiched between two sheets of heavy paper.

What is Drywall?

According to Gyproc SAINT-GOBAIN (Book of Drywall Handbook), drywall is a building material used to create partition as well as non-loading bearing wall and ceilings. It is also used to create many design features including conduit, culvert, drain, duct, arches and other architectural specialties.

Exclusive Drywall Arrangement

It is quick and easy to install, incredibly durable and requires only simple repairs when damaged. In the commercial building, drywall is used to wrap columns to conceal steel beams and is easy and inexpensive way to top off masonry walls above ceilings.

Install Drywall on Wall

Another use of drywall is to add fire resistance to walls and ceilings, preventing the spread of fire so that people can evacuate safely during an emergency.

However, drywall is known by several names in the market and some have been mentioned below so that you don’t get confused.

- Drywall

- Sheetrock® (USG Product)

- Gyp Board

- Gypsum Board

- Plater Board

- Wall Board

- Prison Panel

- Shera Board

Drywall

Why Use Drywall?

Before drywall came to be used widely, building interiors or internal walls were made of masonry with plaster. For hundreds of years, walls and ceilings were constructed by placing layers of wet plaster over large numbers of wooden strips (called laths) or brick/stone masonry.

The wet plaster mortar would eventually harden to form walls, but the installation and repair processes were both time-consuming and difficult to do it well. Therefore, creating plaster walls required several coats to be applied, with a long drying time between each coat.

In addition to its extended installation period, plaster application was quite labour-intensive, that is it requires skilled craftsmen to labour over a small area of a wall for weeks till end/or till completion.

Tough Plaster Work

Here walls that would take weeks to create with plaster could be finished in a couple of days by using drywall and would last longer and that too at less cost to build in certain countries. Damaged drywall can be patched up in a quicker and easier fashion than plaster. Also, it has greater level of fire-resistance and uniformly finished surfaces, linear and levelled.

Simple and Easy Drywall Work

Despite all of these benefits, the use of drywall is slow to catch on with builders, mainly because of cost, as it is still not cheaper than conventional wall.

How Drywall is Made?

According to the Indian Standard Code (IS 2095 – Part I: 2011), Drywall is made primarily of gypsum. Gypsum is a mineral usually found in massive earth beds that look like white sand, though impurities can cause beds to appear pink, yellow or grey. One of the most famous gypsum beds in the United States is the popular White Sands National Monument in New Mexico.

What makes drywall fire-resistent? There is a large amount of water present in gypsum in the crystalline form and that’s why the individual molecules of gypsum are dry. As drywall gets hot, the water crystals begin to destabilize and begin vaporizing as the water reaches its boiling point. The evaporating water crystals keep the drywall cool, protecting the structure behind it.

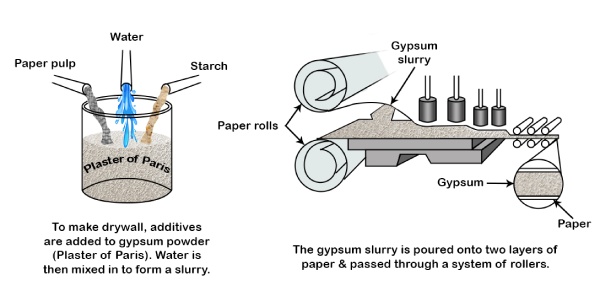

Manufacturing Process of Drywall

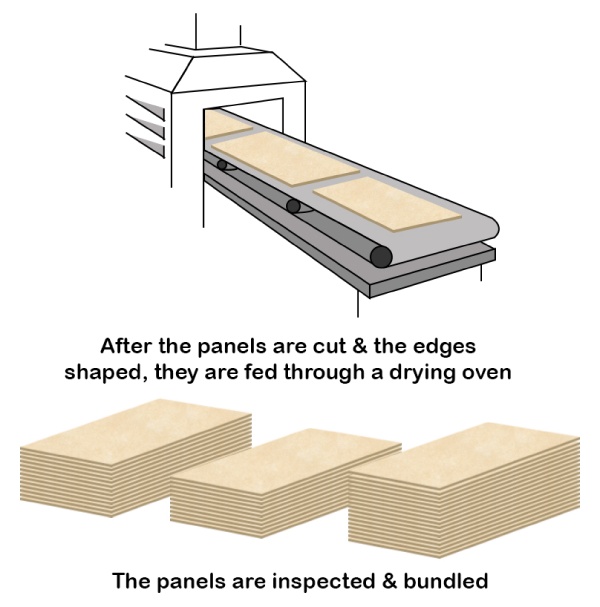

Once gypsum has been mined; it is transported to factories where raw gypsum is mixed with several additives including starch, paper pulp and an emulsifier (or thickening agent), and then blended with water to form a thick paste. The gypsum paste is spread onto Manila paper in 3/8-inch (8 mm) to 3/4-inch (20 mm)-thick layers. Another sheet of Manila paper is then laid on top. The entire formation passes through ovens to heat the sheet at temperatures up to 500 degrees Fahrenheit. This dries the material out and prepares it for cutting. Typical sheets are 4×8 feet, though 4×10 feet and 4×12 feet sheets have become popular recently, as they allow faster installation of taller walls.

Drywall Sheets

Advantages of Drywall

According to the Gypsum Association (Book of Using Gypsum board for Walls and Ceilings), the following are the advantages of drywall,

- Drywall can be erected faster and this makes a difference to the energy costs during their construction.

- Itis light in weight thus the installation is quick and very fast. It also requires less labour.

- It reduces loads and hence saves steel.

- It is also time saving because its installation is too easy and fast and saves interest cost.

- Itis fire resistant due to the crystalline water molecules present in gypsum which will prevent the fire from spreading.

- It is easy to install and is long lasting hence it is cost effective.

- It is easy to paint drywall.

- It is uniform through outs it’s surface.

- Water is not required for installation hence the site remains clean and tidy.

- It can be used for the construction of regular walls, ceilings and also as a partition. It can be removed and installed easily and can be cut in all sizes. This means that you can patch a hole by cutting a piece of drywall and fit it to cover the gap.

- With drywall ceilings and walls, you can install recessed lighting and hang anything you want with ease.

- You get uniformly smooth surfaces without any undulations that too in perfect line and level which is hard to achieve with normal plaster on a brick wall.

- It is free from normal shrinkage and creep cracks occurring in normal brick/stone walls with cement plaster.

Disadvantages of Drywall

- Through drywall can be installed rather easily; the professionals and technicians must be trained because drywall installation and finishing needs to done correctly or you will have problems with the joints or tapes later. They must also prepare the room before the installation because drywall generates a lot of dust which can easily spread all over the house.

- Drywall is not sound proof itself hence it needs sound insulation between two layers.

- The drywall surface is prone to damage. Drywall can be easily damaged since it is not resistant to impact. So, you might have problems with holes, dense damaged corners, tapes coming off, and joints cracking. The good news is that there are drywall repair solutions for such problems.

- As a thumb rule, drywall is not resistant to water. When installed in bathrooms, basements, or other high moisture rooms, it will be affected. And damp drywall will allow mold infestations. If drywall is water damaged, it must be replaced. The only solution to the problem is to get drywall with fiberglass instead of paper. These types of drywall are more water resistant.

- Drywall cannot be erected freely on its own. Wooden/Steel/MS framing is required for this purpose.

- Drywall cannot be used for external walls, until and unless special water-resistant treatments are provided to it. However, they can be easily used for interior spaces.

- Electric/plumbing services or sound insulation cannot be provided on the surface of drywall; they need to be provided between two drywall sheets.

Types of Drywall

Additional additives or different types of papers are used when creating more specialized forms of drywall. While regular drywall is appropriate for most applications, there are many other types that are better suited for special circumstances. The table below will help you choose the correct type for your application of drywall.

(a) Regular Drywall

Application:

- Standard, non-Rated wall, ceilings or architectural features

How It Made:

- Gypsum mixed with water, starch, paper pulp and emulsifier to form standard drywall sheets

(b) Type “X” or “Perlite”

Application:

- Walls or ceilings that require a fire rating beyond 20 minutes

How It Made:

- Fiber strands are added to standard gypsum mixture to maintain the structural integrity of the sheet for a longer period of time in the event of a fire.

(c) Impact Resistant Drywall

Application:

- Used in places where there is huge abuse like school, dormitories, etc.

How It Made:

- Fiber standards are added to the gypsum mixture and thicker paper is used to prevent damage.

(d) Moisture Resistant (Green Board)

Application:

- Bathrooms, Basements or other areas prone to moisture

How It Made:

- Water resistant green paper covers a typical gypsum core.

(e) Sound Board (Quiet Rock)

Application:

- Multifamily units or anywhere where noise transmission is a concern

How It Made:

- Viscoelastic polymers are added to traditional gypsum board. These polymers convert noise energy to heat energy, which is not audible.

(f) Lead-Lined Drywall

Application:

- X-rays rooms or areas subject to radiation

How It Made:

- A 1/16” layer of lead is placed between the gypsum core and the paper backing, blocking X-ray waves from penetrating the wall.

(g) Flexible Drywall

Application:

- Tight arches and curves

How It Made:

- Typical drywall formed into ¼” sheet and wet down before use to make them more flexible.

(h) Blue Board

Application:

- As a base for veneer plaster (1 1/8” layer of plaster installed over drywall to achieve a specific look)

How It Made:

- Typical drywall covered with a special green coating that makes it easier for the veneer plaster to adhere.

Final Thoughts:

Taking everything into account, drywall is a high-performance light-weight partition system consisting of GI steel frame encased with gypsum plaster boards on either side attached through self-drilling drywall screw. The joints are then taped and finished with gypsum jointing compound.

Drywall is used because of its multiple benefits like speed of installation, light weight, accuracy in line, level with undulation free surfaces, aesthetic appeal, versatility, dry construction, Flexibility, excellent performance, environment friendly etc.