Table of Contents

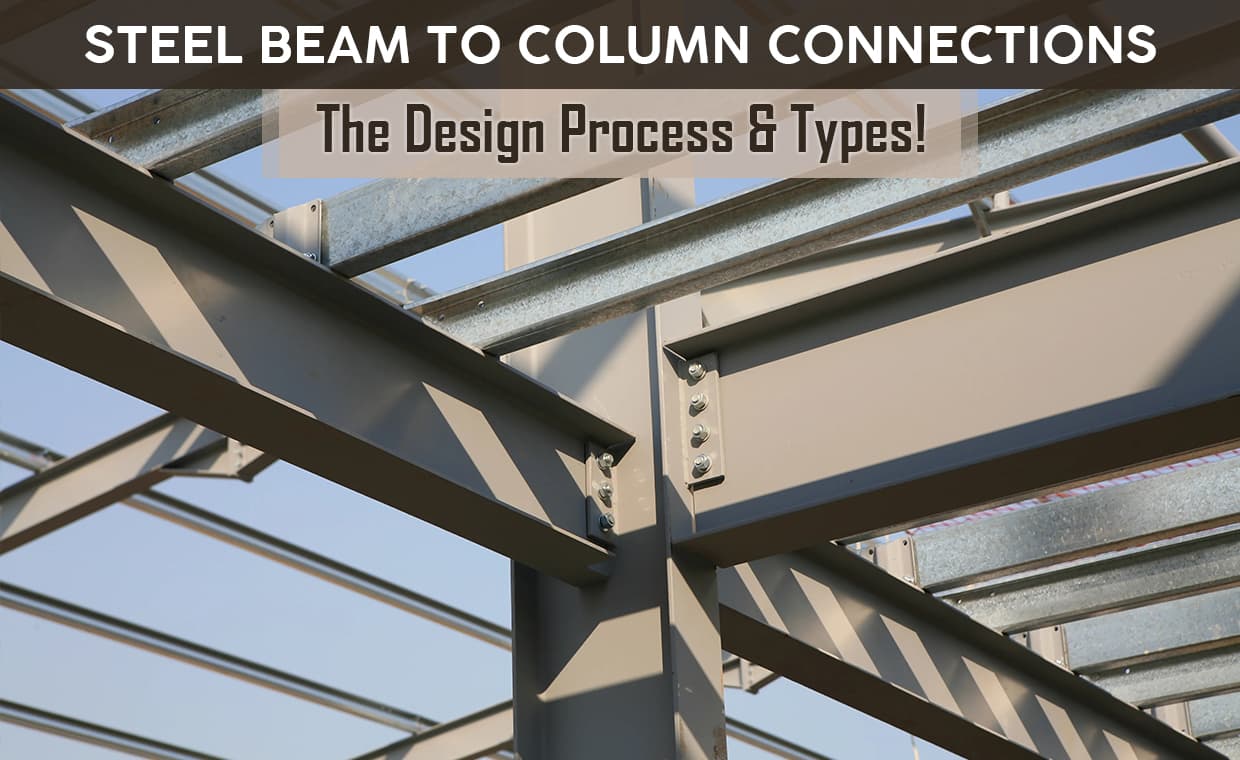

Connections are structural elements used to join different structural members. The steel structures are constructed by adequately connecting the available standard sections. The beam to column connections is an essential part and is designed more conventionally than any other steel structure member.

Hence the analysis of steel structure is extensive. Therefore the steel beam to column connections is complex to analyze and design.

When the structural member fails due to overloading, then there is a general practice to prefer changing the individual structural member rather than the connections and this type of practice affects many structural members. The cost of structural steel includes a significant portion of the cost of beam and column connections. Therefore, for the safety and the economy of structure, importance should be given to designing the connections.

Here, Gharpedia is going to discuss the different types of beam to column connections and their design procedure that is used during steel building construction.

What is a Beam to Column Connection?

According to ‘Jack Moehle’[393] (Author of Book: Seismic Design of Reinforced Concrete Buildings), the beam to column connection comprises the joint plus portions of the beams, columns and slab immediately adjacent to the joint.

What are Different Beam Column Connections?

1. Classification Based on the Rigidity of Connection

a) Flexible Connection / Simple Connection / Pinned Connection / Shear Connection

It is a connection in which no transfer of moment is assumed between the connected parts. It is also considered a hinged connection. In this case, the rotational movement of the joint will be large. It transfers shear or axial force, but not moments. Actually, a small amount of moment will be developed in this type of connection, but it is usually neglected.

According to Indian Standard Code – IS 800:2007[394] (General Construction in Steel – Code of Practice), Simple connections are typically applied in structures up to about five stories in height, where the design is governed by strength rather than stiffness. In such structures separate lateral load resisting system has to be provided in the form of shear walls or bracings.

b) Rigid Connection or Moment Connection

Rigid connections or moment connections in steel structures transfer axial force, shear force and moment to the connecting members. Under such joint rotation, the original angle between the members is retained, that is, rotational movement of the joint will be very small. Also, fully welded connections can be considered as rigid beam to column connection.

According to Indian Standard Code – IS 800:2007[394] (General Construction in Steel – Code of Practice), rigid connections are used in the high-rise and slender buildings, where the stiffness requirements are necessary.

c) Semi-Rigid Connection

Semi-rigid connections fall between the flexible connection and rigid connection. The fact is that any connection will always transfer the shear force and axial force completely but also transfer moment partially.

According to Research paper “Seismic Qualification of Semi-Rigid Connections in Steel Frames” developed by ‘Satish Kumar and Prasada Rao D. V.’, Semi-rigid connections could be used with great benefit to resist earthquake or seismic loads, if they meet seismic design requirements.

2. Classification Based on Connecting Medium (Fixtures / Fasteners)

Based on connecting medium steel beam to column connections are classified as bolted connection and welded connection.

a) Bolted Connection

In bolted connection, the beam and columns are connected by bolts. Two types of bolts are used in bolted connection i.e. bearing bolts and high strength friction grip bolts (HSFG Bolts).

i) Bearing Bolts

The bearing bolts are most common type in clearance holes, also known as ordinary bolts or black bolts. They are popular as they are economical in terms of installation costs and material.

ii) HSFG – High Strength Friction Grip Bolts

High strength friction grip bolts have high strength and are pre-tensioned against the plates to be bolted together, so that contact pressure is developed between the plates being joined. These bolted joints can achieve higher stiffness in shear because of frictional resistance between the contact surfaces.

High strength friction grip bolts (also known as HSFG Bolts) are expensive both from installation and material points of view. They require skilled labour and effective supervision. HSFG Bolts have become very popular recently due to their efficient force transfer mechanism. Moreover, according to ‘Satish Kumar and Prasada Rao D. V.’, their performance is superior under cyclic loading compared to other forms of jointing.

According to Indian Standard Code – IS 800:2007[394] (General Construction in Steel – Code of Practice), where slip in the serviceability limit state is to be avoided in a connection, high-strength bolts in a friction-type joint, fitted bolts or welds shall be used. Where a joint is subjected to impact or vibration, either high strength bolts in friction type joint or ordinary bolts with locking devices or welds shall be used.

b) Welded Connection

In welded connection, the beam and columns are connected by welding. Such connections are an efficient and direct means of transferring forces from one member to the adjacent member in the structure. Welded connections are usually constructed by melting the base metal from the parts to join the weld metal, which forms the connection after cooling.

The welded connections are categorized as fillet weld or butt welds (also known as groove welds) in most cases.

i) Fillet Welds

Fillet welds are made up of two surfaces of adjacent plates to join them together.

i) Fillet Welds

Butt welds or Groove weld are made by butting plate surfaces against one another, filling the gap between contact surfaces with weld metal, and fusing the base metal together. In this type of weld, the contact surfaces are usually cambered to obtain a gap for easy flow and to ensure complete penetration of the weld metal.

You are now aware of the various types of column beam connections. The proper design of Beams and columns in building construction is essential. The majority of buildings collapse due to inadequate beam to column connection detailing and design. Let us know how column to beam connections are designed.

How Do You Connect A Beam To A Column In Steel Structure?

The establishment of any structure is usually carried out in analysis and design steps. Each step provides the structural designer with new information to proceed to the next phase. The process continues until the analysis shows that there is no need for changes in the sizes of the structural members.

According to ‘Kenneth M. Leet et al’[389] (Author of a book – Fundamentals of Structural Analysis), the structures made of reinforced concrete, steel, and wood all are analyzed in the same way. If you want to know relationship of analysis to design then refer our article – What is Beam Column Joints in Reinforced Concrete Building?

According to Indian Standard Code – IS 800:2007[394] (General Construction in Steel – Code of Practice), each element in a connection shall be designed so that the structure is capable of resisting the design actions. Connections and the adjacent regions of the members shall be designed by distributing the design action effects such that the following requirements are satisfied:

Requirements of Beam Column Connection

i) Design action effects distributed to various elements shall be in equilibrium with the design action effects on the connection.

ii) Required deformations in the elements of the connections are within their deformations capacities.

iii) All elements in the connections and the adjacent areas of members shall be capable of resisting the design action effects acting on them.

iv) Connection element shall remain stable under the design action effects and deformations.

Beam To Column Connection Design Procedure

The Design Procedure of Beam to Column Connection in Steel Structure Consists of the Following Basic Steps:

According to Indian Standard Code – IS 800[394], Design shall be on the basis of any rational method supported by experimental evidence.

i) Residual stresses due to installation of bolts or welding normally need not be considered in statically loaded structures.

ii) Connections in cyclically loaded structures shall be designed considering fatigue.

iii) For earthquake load combinations, the connections shall be designed to withstand the calculated design action effects and exhibit required ductility.

- Bolts used in a structure designed to resist earthquake loads shall be fully tensioned HSFG bolts (high strength friction grip bolts) or turned and fitted bolts.

- Welds used in a structure designed to resist earthquake loads shall be complete penetration butt welds, except in column splices.

- Bolted connection shall not be designed to share load in combination with welds on the same faying surface.

Summing up, Beam to column connections design is essential for the safety and economy of steel structures. Economical connection designs mostly take into account the practicalities of fabrication and erection.

However, based on a clear understanding of the load transfer path, the beam column Connection design should be simple. In addition, the detailing of the steel beam to column connections should be simple and based on repetitive use of standard practices to facilitate ease of fabrication and erection. Thus, it will accrue speed and economy of the project.

Thank you for taking the time to read this!

Are you interested in learning more about beam-column joints in reinforced concrete and wooden structures? To learn more, click on the following links:

What is Beam Column Joints in Reinforced Concrete Building?

Types of Beam to Column Connections in Timber Structure Design

Image Courtesy: Image 1