Why should You Test

A building is a very complex structure because it consists of various construction materials, such as cement, sand, brick, aggregate, wood, reinforcement and many more. Therefore, it’s essential that all the materials perform best and its performance depends on the quality of the materials. If any of these materials fail in their desired performance, it adversely affects the performance and durability of the structure as a whole.

Role of Different Materials

Every material has to be strong enough and essential to possess certain properties such as physical and chemical. Thus, every material needs to possess certain minimum properties so that it can play its role.

If you use any construction material without knowing its quality, it will affect your construction and will make your construction good or bad. Hence tests are very important to ensure that you are using the right material and construction will be of sound quality. To ensure the quality of material, there is various kind of tests available.

Here we are discussing various “Brick Test”.

Bricks

Why Brick Test is Important?

Brick is one of the oldest building material and it still continues to be the most popular and leading construction material. As an ingredient, it consists of clay having a major amount of silica and alumina and small amounts of lime, iron, manganese, sulphur, etc.

Bricks are mostly used in construction because of being cheap, locally available, durable and easy to handle and work with. Clay bricks are used in piers, footings, masonry construction, i.e. exterior wall, interior wall, partition wall, and over load-bearing structures. Bricks can be used both for structural, i.e. load bearing or non-structural, i.e. partition walls purposes.

The Important Physical Properties of Brick:

- Shape

- Size

- Colour

- Frog

- Water absorption

- Effloresce

- Compressive strength of Brick

Field Tests on Brick

A field test on bricks gives the idea about its basic quality based on its shape, size and colour at first observation without any big appliances. They are the very common and easiest way to check the quality of brick. Field tests of brick are very helpful on the site. Some very common tests of brick that is followed to find if brick is good at first observation are as follows:

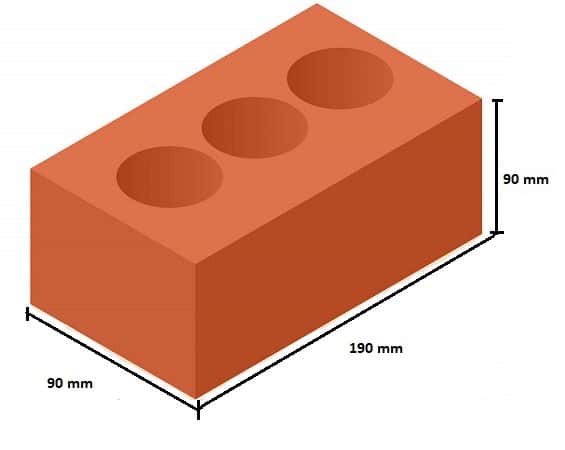

- Shape and Size of Clay Bricks: The clay bricks should have a uniform rectangular plan surface, as per standard size and sharp straight edges. BSI recommends the standard size of brick is 190 mm x 90 mm x 90 mm and constructional size is 200 mm x 100 mm x 100 mm.

Size of Brick

- A hardness of Clay Bricks: The clay bricks should be sufficiently hard when scratched by a finger-nail no impression should be left on the brick surface.

- Colour of Clay Bricks: The clay bricks should have a uniform deep red colour throughout. It indicates the uniformity of chemical composition and the quality of burning of the bricks.

- Texture and compactness of Clay Bricks: The surfaces should not be so smooth to cause skidding of mortar. The clay brick should have a pre-compact, homogeneous and uniform texture. A broken surface should be free form cracks, holes grits or lumps of lime.

- Soundness of Clay Bricks: When two clay bricks are stuck together, a metallic ringing sound should come.

- Thermal Conductivity of Clay Bricks: Generally, we are not conducting any test for thermal conductivity because the thermal conductivity of clay brick is low, i.e. it protects from heat.

- Basic Strength of Clay Bricks: When dropped flat on the hard ground from a height of about one meter, clay bricks should not break.

Brick Efflorescence of ClayBricks: Presence of soluble salt in the bricks is dangerous. They produce a grey or white powder layer on the brick surface by absorbing moisture. To find out the clay bricks efflorescence, bricks are immersed in water for 24 hours then dried in the shade. If there is any white colour deposit on the surface of the brick then the brick is not good for construction.

Laboratory Tests on Brick

Laboratory tests on brick determine the mechanical properties of brick and give a scientific approach to ensure the quality of bricks. It is essential while purchasing the brick and examine the properties for the quality of construction.

Followings brick tests are performed in the laboratory to determine the quality of brick.

01. Water Absorption of Bricks

The brick is porous by nature and Porosity is the ability to release and absorb moisture. Therefore, it tends to absorb the water or moisture. It’s an important and useful property of brick. But if brick absorbs more water than the recommended result, than it affects the strength of brick as well as durability of the structure and of course will damage plaster and paint over walls.

(a) Use of Water Absorption of Bricks:

Water absorption test is performed to know the percentage of water absorption of bricks.

(b) Recommended Result of Water Absorption of Bricks:

Water absorption of bricks should not more than 20 % by its dry weight.

(c) Why Bricks Fails in Water Absorption? & What if Test Fails?

If brick fails in the water absorption test, possible reasons are like manufacturing error, insufficient burning, error in clay composition etc. and If brick fails in water absorption as well as efflorescence than never never never use those bricks because you will land in permanent problems and it will be very difficult to solve them.

(d) Standard Guidelines for Water Absorption Test of Bricks:

There various standard guidelines available for water absorption test of bricks such as IS 3495 (Part 2) 1992, ASTM C 67, BS 3921:1985.

(e) Apparatus of Water Absorption Test of Brick:

Water bath, weight balance, and oven are required for performing this test

Water Absorption of Brick

02. Compressive Strength of Brick

The compressive strength of the brick is the most essential property of the bricks because in the construction, bricks are widely used in masonry and it also plays a significant role as a load bearing component.

When bricks are used in any structure, the bottom-most layer of the brick will be subjected to the highest compressive stress. Therefore, it is essential to know that any particular brick will be able to withstand that load or not.

(a) Use of Compressive Strength of Brick:

This test is performed to know the strength of bricks because it affects the overall structure in the way of quality, durability and serviceability.

(b) Recommended Result of Compressive Strength Test of Brick:

Test result recommendations are as follows:

- For first class bricks, it should not less than 10 N/mm2 (102 kg/cm2).

- For second class bricks, it should not less than 7 N/mm2 (71 kg/cm2).

- For third class bricks, it should not less than 3.5 N/mm2 (36 kg/cm2).

In India, the northern and the eastern region produce bricks having good compressive strength than the western region because the western region has black cotton soil, while the soil is good in Gangetic region.

Generally, the compressive strength of brick having 7.5 N/mm2 is considered as a good. However, in some part, none of the brick even do have 3.5 N/mm2 of strength. You can use given bricks for partition walls but use with great care for load-bearing walls after having a good structural design.

Why Compressive Strength Test Fails? & What if Test Fails?

If the test result is not as per recommendation, there are many reasons behind it such as the clay composition, degree of burning like over burning or insufficient burning, error in the testing appliance or testing procedure etc.

If bricks fail in strength as well as water absorption test than do not use it.If bricks are irregular in some minor shape/size than it can be corrected with mortar. If not then you can consult your brick supplier or brick manufacturer for replacing it.

Compressive Strength of Brick

Standard Guideline of Compressive Strength Test of Brick

There various standard guidelines available for testing of brick such as IS 3495 (Part 1) 1992, ASTM C 67, BS 3921:1985.

Apparatus of Compressive Strength Test of Brick

Compression testing machine or universal testing machine is required for the compressive strength testing of bricks.

We performed a brick test to ensure the desired quality of bricks. The good quality of bricks is must for the long life of the structure and it also reduces the maintenance. In Asian countries, most the manufacturers of brick are illiterate or semi-literate. They are not bothered about the bricks properties, strength etc. and also don’t conduct any test like other manufacturers, i.e. they do not have any their in-house laboratory nor they do bother to carry out tests, unlike other manufacturers. Hence it is ultimately the buyer who will have to be more careful while buying and using. Hence brick testis the most essential for the home builders/civil engineer.

Also Read:

Brick Flooring: All You Need Know

Various Types of Red Brick Based on Manufacturing Method

AAC Blocks Vs Red Bricks: How to Make the Right Choice