Mix design is a process of selecting the proportions of the ingredients for concrete with the relative proportions of all ingredients you can achieve the concrete of desired strength and properties. The mix design contains various steps, calculations and laboratory testing to find the right mix proportions. In all the other steps water-cement ratio is the most important factor which affects the properties of concrete.

Concrete

Water-Cement Ratio is defined as the ratio between the weight of the water to the weight of cement. In general terms w/c ratio means, how much water is required for the particular mix.

We all know that the water-cement ratio will directly affect the strength of concrete. The strength of concrete either increases or decreases, will generally depend upon the w/c ratio. It can also affect the workability of concrete, which is most important to concreting process like mixing, placing and compacting. Therefore it’s most important to calculate water-cement ratio while mix design. As it is very important for both fresh as well as hardened concrete.

Steps to Calculate Water-Cement Ratio while Mix Design as per IS 10262-1982

(a) Data Collection

To calculate water-cement ratio for mix design, we need to collect some data like

- Target mean strength of concrete.

We can calculate it from,

ft = fck + 1.65 S

where,

fck – The characteristic compressive strength of concrete (Grade of concrete which you want to design),

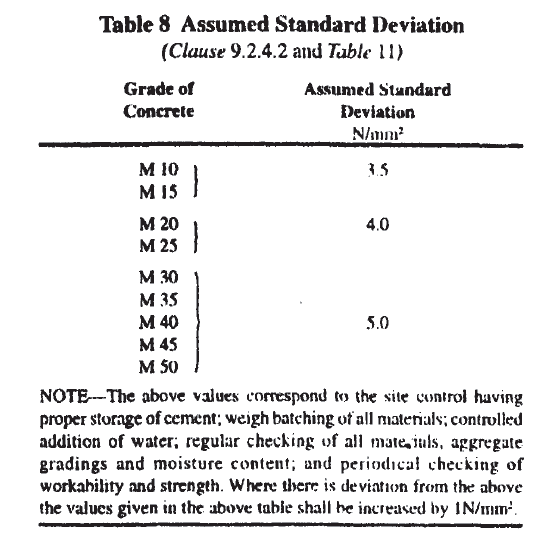

S – The standard deviation obtained from the below table,

Standard Deviation Chart

- Ideally, the cement we are going to use in concrete mix design, we should test the compressive strength of that cement at 7 day. We can get this result from testing the compressive strength of cement or we can also get data from manufacturer of cement.

- Knowledge about the environmental exposure condition in which the concrete will be used. Environmental exposure condition like mild, moderate, severe, very severe, extreme etc.

(b) Steps to Calculate Water-Cement Ratio

Step-1

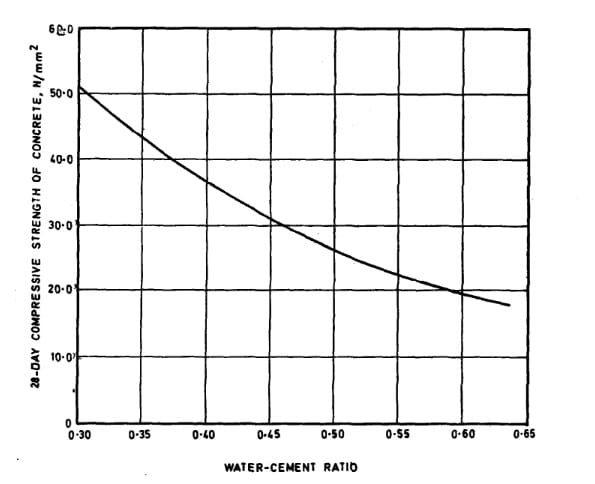

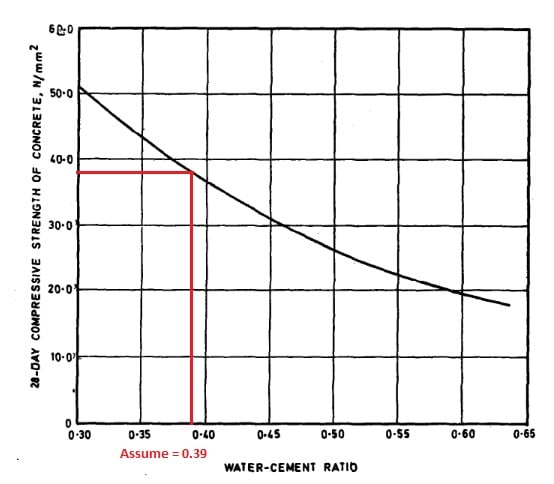

Calculate water-cement ratio from the given graph of 28 days characteristic compressive strength of concrete and w/c ratio, here we used target mean strength.

Compressive Strength vs W/C Ratio Graph 1

Step-2

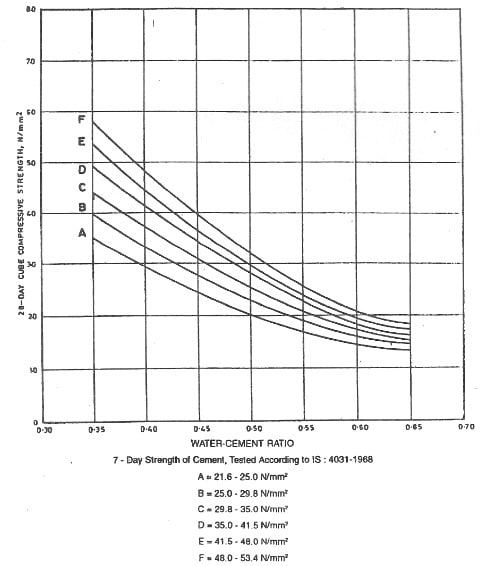

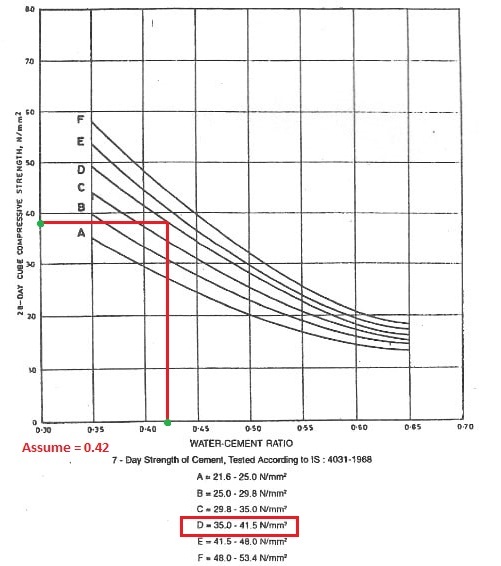

Calculate water-cement ratio from the given graph. In this graph, curve line A to F indicates the 7-day compressive strength of cement and 28 day-compressive strength of concrete means our target mean strength.

Compressive Strength vs W/C Ratio Graph 2

Step-3

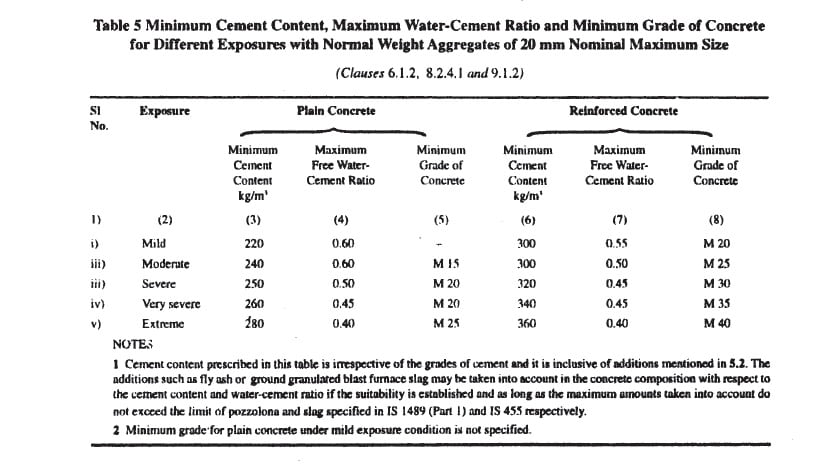

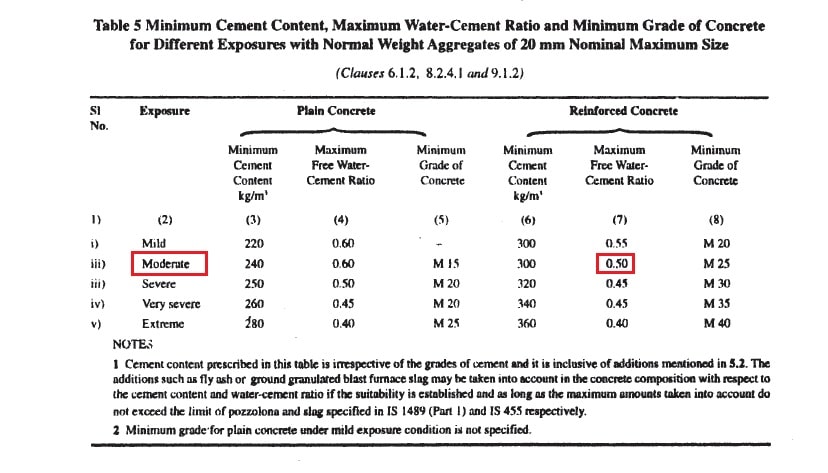

Calculate water-cement ratio from the maximum free water/cement ratio according to environmental exposure condition as per table 5 of 456-2000, this is the limitation given by Indian Standard. Limitation chart for w-c ratio shows the maximum value of the w-c ratio as per IS 456: 2000 which can be adopted during mix design.

Limitation Chart for W/C Ratio

The lower value of the above three values should be adopted as W/C ratio for mix design.

Example

Calculate Water-Cement Ratio for Concrete Mix Design – M30 Grade Concrete for R.C.C Work

Data Collection:

Grade Designation = M-30

Exposure condition= Moderate

Cement = OPC 53 Grade, assume 7- Day compressive strength of Cement is 37 N/mm2

Fck = 30 N/mm2

Standard deviation for M-30 is 5 N/mm2

Target mean strength ft = fck + 1.65X S

= 30 + (1.65 X 5)

= 38.25 N/mm2

Step-1

Here, 28 -day compressive strength of concrete = target mean strength= 38.25 N/mm2

Evaluate Compressive Strength vs W/C Ratio Graph 1

Hence, we assume w/c ratio = 0.39

Step-2

Here, 7-day compressive strength of cement= 37 N/mm2

Hence, we used curve line D.

28 -day compressive strength of concrete = target mean strength= 38.25 N/mm2

Evaluate Compressive Strength vs W/C Ratio Graph 2

Hence, we assume w/c ratio = 0.42

Step-3

Here, Exposure Condition= Moderate

Evaluate Limitation Chart for W/C Ratio

Here, the limited value of the water-cement ratio is 0.50 for moderate environmental exposure.

Hence, we take w/c ratio = 0.50

Now compare all above the three values,

- 39

- 42

- 50

The lower value of the above three values is adopted as W/C ratio for mix design. Hence our w/c ratio is 0.39.

Water-cement ratio is the most important factor which can affect the properties of concrete in the plastic stage as well as hardened stage. So always be careful while selecting the w/c ratio. Because of improper calculation of water-cement ratio gives an adverse effect like segregation, bleeding, decrease in strength of concrete, decrease in durability of concrete etc. These steps will help you to calculate water-cement ratio in the design of the concrete mix so that you can control the quality of concrete.

Also Read:

What is Bleeding in Concrete?

When was Concrete Invented? – A Brief History

Image Courtesy: Image 1