Cement is perhaps the most important construction material that is widely used in modern construction. Cement is generally deployed to prepare concrete and mortar which are used to make RCC framed structures. The binding properties in cement facilitate it to easily mix with aggregates and form a homogeneous mixture, which hardens to give a stone-like strength. The strength and durability of the structure are mainly dependent on the strength of the cement.

But rampant adulteration has seeped into this product also and lay persons are many-a-times unaware of pointers to be kept in mind while purchasing and storing cement. Gharpedia shares some useful cues through this article –

What to Check Before Buying Cement?

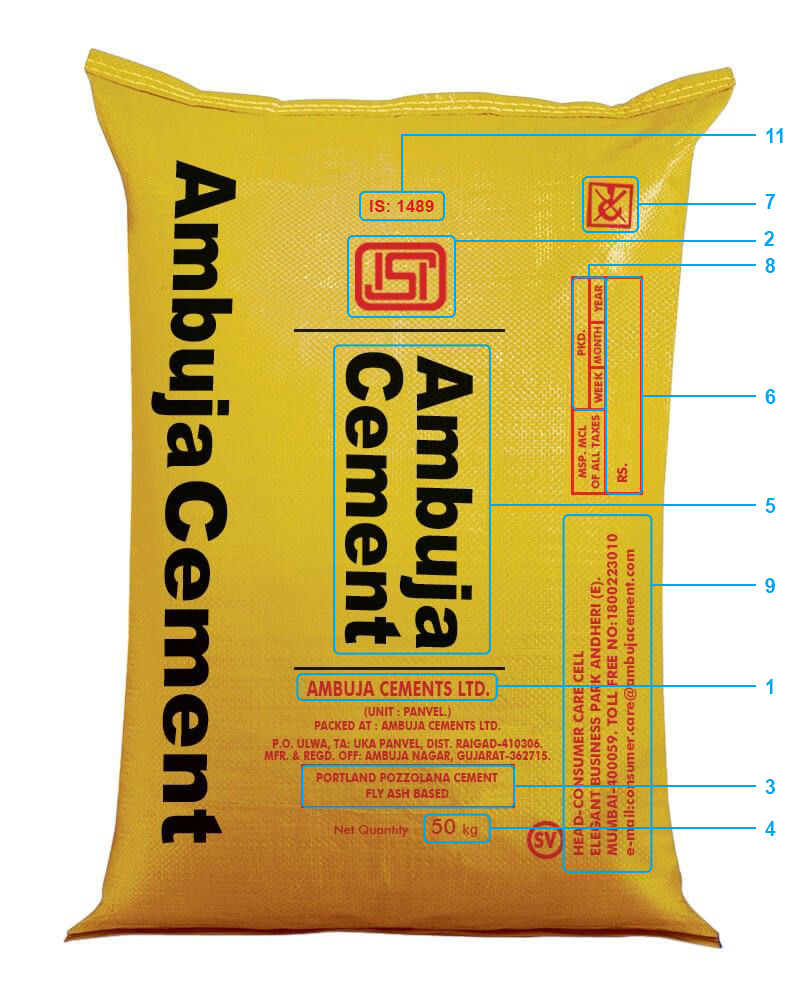

There are many manufacturers of cement worldwide. They frequently adopt unfair practices to manufacture and pack cement with the sole objective of increasing their profit. As some of us are well-aware, the cost of cement is more than other construction materials (coarse aggregates, fine aggregates etc.) and it also affects your overall project cost. Hence some steps of caution may go a long way in ensuring that we are purchasing an authentic product and nullifying the chances of duplicate inferior cement bags arriving on our construction site. The simple reason being – duplicate or adulterated cement decrease the life of the structure. To as certain that such a mishap does not befall you one needs to check some basic standard specifications before buying cement. You must check the information that is printed on a standard cement bag. Here are some points to check on a cement bag, at the time of purchasing or receiving cement bags to ensure the quality –

Points to Check on a Cement Bag Before Buying

01. Properly read the manufacturer’s name and their registered trademark. If the trademark and name is not properly printed or there is any spelling mistake, then the cement bag may be a duplicate version.

02. The ISI mark should be printed on the cement bags in black colour. The ISI mark confirms that the cement packed in the bag has fulfilled every requirement of the specifications.

03. The grade and type of cement is an important point to check on a cement bag. A cement bag of OPC 53 must carry the following words – Ordinary Portland Cement, 53 Grade or Ordinary Portland Cement, 53-S Grade whichever is applicable.

04. The net weight of cement in kilogram i.e. 25 Kg, 50 Kg etc. must be mentioned on the cement bag.

05. Check the brand of cement. It is important that the cement is of a reputed brand. One must also check the cut-sheet provided by the brand, to gain an understanding regarding the technical details of the product.

06. MRP (Maximum Retail Price) is an important point to check on a cement bag. The retailer or seller can fool us by selling the cement bag at a price higher than the MRP. Hence checking the MRP before buying the cement bag will help the consumer to avoid any kind of fraud.

07. Ascertain that the phrase – ‘Use no Hooks’ or an equivalent symbol is printed on the cement bag.

08. The batch/control unit number in terms of week, month and year of packing must be mentioned on the cement bag. It is advisable to use a cement bag which is recently packed, usually less than 3 months.

09. The address of the manufacturer must be mentioned on the bag to facilitate contacting him for future enquiries.

10. The type and percentage of performance improver(s) added, if added must be mentioned on the cement bag.

11. Particular IS code number should be printed on the cement bag. i.e. if you have ordered OPC 53 grade cement, then “IS-12269-1987”[210] should be printed on the cement bag; and if you have ordered Portland Pozzolana Cement (PPC), “IS 1489 – 1 -1991″[168] & “IS 1489 – 2 -1991”[363] should be printed on the cement bags.It is essential to check if the aforementioned points are mentioned on a cement bag, prior to purchasing it. This will ensure that – the cement bags are from a reputed manufacturer; their quality is standardized; and chances of loss to the customer are minimized or nullified. After buying cement bags, it is critical to properly store them and use them within a few days.Gharpedia has also published an article on how to store cement bags on site. To know the best tips and tricks to follow on site, please click on the link

Moreover, you can read regarding quality checks to be done on cement and sand at site

Ways to Check the Quality of Sand at Site!

Image Courtesy: Image 1