Cement is the most crucial and universally used material without which one cannot think about concrete construction. It is very famous as a building material with concrete experts due to its profuse and numerous properties. Depending upon the climatic conditions of a particular region and taking into consideration the requirement, various types of cement are manufactured all over the world to full fill the purpose of construction. As per ‘World Cement Association’, the prices of cement are rising up worldwide since 2017 and the volumes are growing larger in both mature and emerging markets together for the first time thence after the financial crisis.

What makes it popular and preferable in the construction industry is because of its significant property of strength. Cement is a dry powder which should not be confused with concretes or mortars, but it is an important ingredient for both. Let us see how to get concrete or mortar. In order to get the durable concrete or mortar, first dry mix the concretes or mortar ingredients and then add water to that mix. When the cement reacts with water, the whole mix will start to set, and it will finally gain strength once it hardens. The hardened concrete or mortar provides strength, durability and longevity to the structures and contributes in their valuable service life.

The bad quality of cement reduces the strength of cement thereby affecting the service life of buildings or houses. Construction with bad cement always leads to the waste of money and at times, it may also cost the safety of homeowners.

Cement is produced in bulk in the factories. After going through various processes, it comes out as a final product. This cement is transported on site and stacked on site. The cement has a tendency to quickly react with water. Thus, during transportation or when stacked on site, if by any chance it comes in contact with water in the form of moisture or any other means, the chemical reaction starts between the cement and water. Once the reaction takes place, the quality of cement never remains the same. Such cement cannot achieve desired strength as compared to the fresh or dry cement. Hence, it is very essential to check the quality of stacked stock of cement on construction site before using it.

Let us understand how to check or test cement on construction site.

Following are the various easy site tests which are carried out by every concrete expert on construction site. Even a normal person can effortlessly perform these tests and can comfortably find out whether the cement is of good quality or not.

Easy Cement Tests to Check the Quality of Cement at Construction Site

01. Checking the Manufacturing Date of Cement

The manufacturing date of cement should be checked on the cement bag. As discussed above, fresh cement will have good quality but under the effect of environment, and with respect to time, the quality is affected and so is its efficiency. Hence, as a general practice, first check the age of cement by checking the printed manufacturing date on cement bags before you use it on construction site. To know more, read

Can I Use One-Year Old Cement Bags?

Does Cement Loses Its Strength Over a Period of Time?

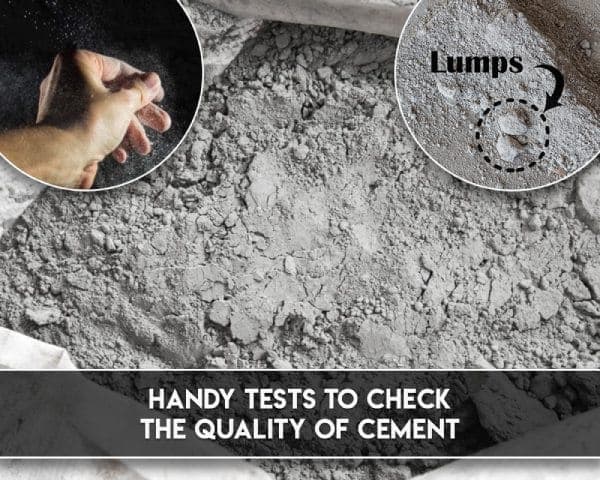

02. Checking the Presence of Lumps Inside the Cement Bags

Open the bag and take a good look at the cement. Ensure that you do not see any lumps over. Lumps are formed when the packed cement bag comes in contact with the moisture. If lumps are visible in the cement bags, it indicates that the strength of cement is being compromised. Hence necessary precaution must be taken while staking the cement on site. In order to know how to protect the cement from moisture, please refer the following: Precautions while Storing Cement Bags in Godown.

03. Float Test

The excess amount of dust present in the cement reduces the strength of cement. Hence cement is tested by throwing small quantity of cement in a bucket of water. If the cement floats on the water for a few minutes before it sinks, such cement should be considered as good quality cement. The immediate sinking of cement indicates the presence of impurities in the cement which indicates the bad quality of cement. Such cement will reduce the strength of cement.

04. Colour Test

Ordinary Portland cement has normally dark greenish-grey colour. Hence, check the colour of cement before you use it on the construction site. The light grey colour of cement indicates that the cement may be an older one or it may be under the attack of moisture.

However, one should not get confused with different shades of cement. Nowadays, various types of cement are available in the market with different shades, depending upon the raw materials used in the manufacturing of cement. Do you know that different shades of cement can affect the quality/strength of cement? To know the right answer, please refer shades of cement.

05. Temperature Test

Cement has a tendency to remain cool while it is in bag. This means, when you touch it, you feel cool. Hence insert your hand into the cement bag to check the temperature of cement. If the inside temperature of cement is less, the cement should be considered of good quality.

06. Test to Check Addition of Another Substance

Cement is a very fine material. Hence when you rub the cement between your fingers, it gives a smooth feeling. Such cement should be considered good cement. However, if you feel gritty or feel rough, it means that other substances like silt are present in the cement which may lower the strength of it.

07. Testing the Oduor

The presence of clay or silt also can be evaluated by smelling the cement. If the cement contains too much of pounded clay and silt as an adulterant, the paste will give an earthy smell.

08. Setting Test

Take 100g of cement and a small quantity of water. Now make a stiff paste of it. Prepare a cake with sharp edges and put on the glass plate and slowly take it underwater in a bucket. See that the shape of the cake is not disturbed while taking it down to the bottom of the bucket. After 24 hours, the cake should retain its original shape, and at the same it should set and attain some strength.

As per ‘Portland Cement Association’, cement is manufactured through a closely controlled chemical combination of calcium, silicon, aluminium, iron and other ingredients.

Though the cement is produced in a controlled environment and carefully packed, somehow it becomes impossible to maintain the quality of cement due to the various reasons. In such cases, the structure does not perform well.

Final Thoughts

It is very essential to ensure the quality of cement before using it. This can be done at the construction site by using some simple aforementioned cement tests. Remember that, it is very important to check the quality of cement on the construction site before it is used. Well, it is not possible to check all the engineering properties of cement on site, but you can easily perform simple physical field tests on cement and quickly get the idea of cement quality.

Nowadays, there is a professional approach to everything and manufacturers of cement are walking hand-in-hand. Thus, to ensure customer satisfaction or address any grievances, customer care number is printed on the cement bags so that you can contact the manufacturer for future assistance. The key to long life house is not compromising on the quality of cement. In case of doubt, please do perform a laboratory test to ascertain the quality of cement. Good quality cement ascertains a good quality home – Home Sweet Home!

Image Courtesy: Image 2, Image 4, Image 6, Image 7(a), Image 7(b)