Modern Portland cement is a very finely ground material and that makes it highly hygroscopic, which simply means, it rapidly absorbs moisture not only in the form of free water but it also absorbs moisture from the air. It is necessary, therefore, to protect it from dampness before it is used, if it is to use to fulfill its intended function. A small reaction of cement with moisture can results into the lumps in cement bag. As a general rule no one likes to use defective material so does same apply for a cement bag. Cement bag with lumps inside will not provide desired strength of concrete construction in future. Not only moisture, but cement should be protected from the rain, direct sunlight, wastage, robbery, etc. To know more, read effect of moisture on cement bag.

To protect the cement, it should be stored well in cement godown. Proper arrangements should be made in cement godown to ensure the good condition for storage of cement for the construction projects.

Storage of Cement

Following are some basic points which one should be considering while storing cement either in warehouse or godown.

01. To Save the Cement from the Moisture Effect

It is found that cement will maintain its quality if moisture is kept away from cement. Absorption of 1 to 2% of moisture has no significant effect on quality of cement. But if moisture absorption exceeds 5%, the cement becomes totally useless. Hence cement should be stored in such a manner that no moisture or dampness is allowed to reach cement either from the ground or from the environment etc. This becomes particularly important during the humid season and in coastal regions when atmospheric air contains higher amount of moisture in it.

(a) Raised Floor to Protect the Cement from the Ground Moisture:

Undoubtedly, ground soil always has a moisture. When you store the cement bag on the ground without any provision on floor, cement bag will absorb the moisture from the ground. It may create lumps in cement bag. Hence cement bags should be stacked 150 mm to 200 mm above ground on the platform made by wooden batten and planks or by other means. Also cover the platform with an impermeable plastic sheet underneath.

(b) Keep Distance from Side Wall to Protect the Cement from the Atmospheric Moisture:

One important factor to consider while storage is keeping a safe distance from the side walls, ensuring isolation of cement bags from the leaky and damp walls especially if the walls are exposed to the external atmosphere.

A space of 600 mm minimum shall be left all-round between the exterior walls and the cement stacks.

02. Proper Way of Stacking of Cement Bags in Cement Godown

The arrangement should be such that it is convenient both for stacking and removal of cement bags and it also leaves adequate space for movement and inspection of bags for counting purposes etc.

In between individual pile a passage of 600 mm should be provided for easy access.

Cement bags should be stacked in a stepwise manner on the wooden plank so that plank is stable and will not topple/overloaded at on one side.

In the stacks, the cement bags shall be kept close together to reduce the circulation of air as much as possible. Cement is a hygroscopic material. Atmospheric air contains a higher amount of moisture in it. Moisture is the first and the greatest enemy of cement. Cement has characteristics of attracting moisture; therefore, it should be stored in such a way that moisture should not reach to it. Cement gets set in form of lump if moisture happens to approach the cement. Hence such cement where the initial setting has taken place cannot be used for any construction purpose.

Also Read:

What is Setting Time of Cement?

Test to Determine the Setting Time of Cement

It is advisable to never stack more than10 cement bags over each other as this will lead to lumping under pressure. Sometimes it is also difficult to stack one bag over the other as this may cause them to fall down.

In stacks more than 8 bags high, the cement bags shall be arranged alternately lengthwise and crosswise so as to tie the stacks together to give the stack better stability and minimize the danger of toppling over.

The width of the stack shall be not more than four bags length or 3 meters.

03. Removal of Cement from the Godown or Warehouse

Cement should be removed in order of its storage period, i.e. the rule of first in, first out should be followed.

Cement bags should be stacked in a manner to facilitate their removal and use in the order in which they are received.

A label showing the date of receipt of cement should be put on each stack to know the age of cement. Check the manufacturers’ date and use the oldest stock first accordingly.

Never remove all bags from the top layer. It is recommended that bags should be removed from two or three layers in a stepwise manner so that the pile is stable and will not topple.

Sometimes ‘warehouse pack or lump’ is developed due to pressure on the bottom layer of bags. This can be removed easily by rolling the bags when the cement is taken out for use. Roll the bags once or twice to break the lumps if any.

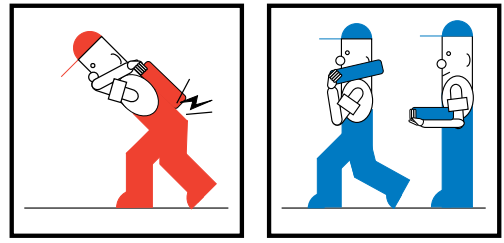

04. Never Use Hook to lift or Stag the Cement Bag

Do not allow hooks to facilitate in lifting while storing the cement. Using hooks has been marked as a detrimental practice for handling of bags as it exposes the cement to the open atmosphere which may get damp and misty. Hence to avoid any negative effects of atmosphere to affect the quality of cement, it is best to provide the workers with proper cement handling tools.

05. Protect the Cement from Chemical Effect

Never store the cement bags with fertilizers or other products, as any contamination can affect the quality and performance of the screed. Different types of cements shall be stacked and stored separately.

06. Store Leftover Cement Carefully

Always first use left in torn or opened bags. But ideally, they should be re-bagged in plastic bags or heavy duty garbage bags and the mouths sealed securely with string or tape.

07. Storage of Cement in Monsoon

In monsoon or in situation when the cement is to be stored for unusually long periods, the cement stacks should be completely enclosed by 700 gauge (175 microns or 0.175 mm) polyethene sheet or some other water-proofing membrane materials.

Plinth level of the godown/warehouse should be higher as compared to the adjacent locations, so that water accumulating in the surroundings does not enter inside.

08. Arrangement in Cement Godown or Warehouse

- Avoid storage of cement in godown which is established in the basement; preferably the storage should be done in the first or higher floors.

- The entry to the warehouse should be having a slope towards the outside and under no circumstance the level should be lower or of the same level as the adjacent road.

- The slab of the shed/godown can be either of leak proof reinforced concrete slab or of adequately sloped water tight galvanized/asbestos sheets.

- The small windows are provided at sill level and normally kept tightly shut. Due to this the moisture or rain water is prevented from entering into shed.

- The height of the plinth of the cement godown should be built in such a way that the bottom level of the truck is of the same height as that of the godown so that, the loading/unloading operations of the bags are done conveniently.

- The floor of the shed should be of at least 150 mm thick densely compacted concrete slab on rubble soling. It should be in proper line, level and slope.

- The drainage system should be checked and maintained on regular basis.

- Cement is used to make concrete, mortar, etc. which are majorly responsible for the future life of structure. The good quality of cement leads to the higher strength of concrete, mortar, etc. Hence, there ain’t any harm in stating that, cement increases the life of house or structure. Therefore, always try to store the cement as specified as above to maintain its quality and integrity. Do share your views, experiences and difficulties you may have face during the storage of cement bags.

Must Read:

Different Types of Concrete Mixers/Machines

Types of Concrete Batching Plant: Know Before Concreting!