Do you buy gold without a Hallmark or ISI mark? No, right? Then why to buy tiles that do not stand up to the standards of quality! After all, you will be seeing them for many years. Those attractive shiny looking vitrified tiles that you select for your homes may have some defects that may kill the look of your beautiful floor and wall surfaces. Let us have a look at defects in vitrified tiles which are not easily visible.

Courtesy - Pinterest

How are Vitrified Tiles Made? What causes a Defect in it?

Vitrified tiles are factory-made ceramic tiles manufactured by compressing and firing at very high temperatures say 1200 to 1230°C. They are polished to achieve its smooth looking character same as marble and granite. At times, these processes may produce defective pieces depending on the different factors like the temperature of the kiln, pressure on tiles, speed of conveyor belt, composition, etc.

If any of the flaws are noticeable through a naked eye, we identify it as a poor quality of vitrified tiles!

Do make sure to analyze the following defects in vitrified tiles before buying them!!!

01. Bowing Defect

When tiles manufactured, they are not flat and have curvature in it. It is called a bowing defect. Tiles are supposed to be flat to avoid joint lips when laid without grouting. Tiles that have bowing or curvature effect can be checked easily by placing them on a straight surface.

Bowing Defect

Courtesy - tilingforum

02. Defect in Edges

Many of tiles have warped edges and bevelled edges. When such tiles are laid together, there is a definite unevenness found at the joints of the tile, thus resulting in the non-uniform surface. A layman may have to use a grouting material to hide this defect. Grouting material is very expensive, thereby increasing the flooring cost.

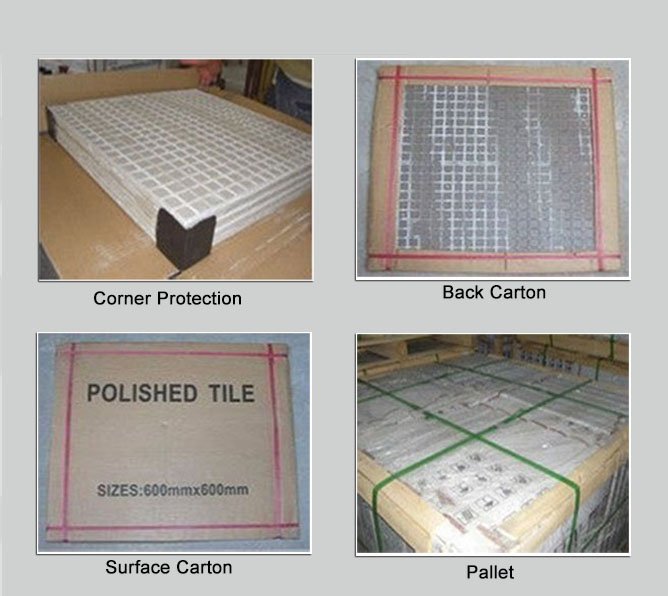

03. Chipped Corners

Vitrified tiles are available in large slabs with size ranging from 1.5 ft to 5.25 ft (450mm to 1600mm). Transporting such huge tiles can be tricky sometimes, if not done carefully it results in chipping of corners of tiles. It is recommended to use packaging corner protector so that the corners remain intact such chipped corners will collect dust and will give an ugly look!

Chipped Corner

Packaging Materials

Courtesy - alibaba.com

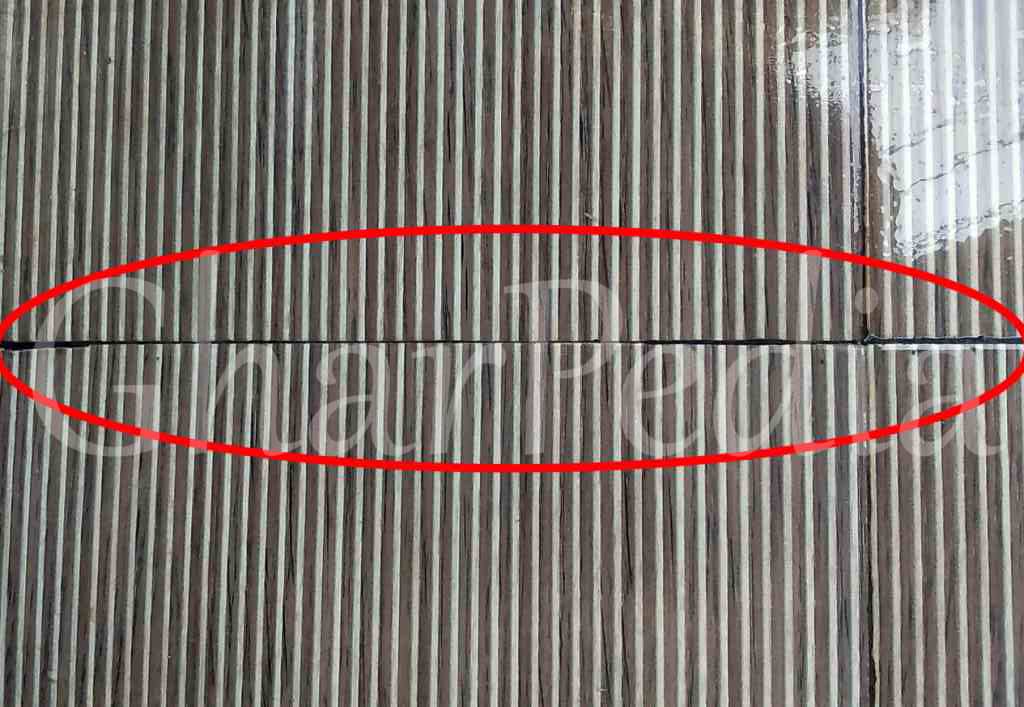

04. Uneven Sizes

The sizes may vary by few millimeters, but when laid together, these errors are cumulatively resulting in huge differences. If size difference is noticeably huge, the joints of tiles will not match. To cover such defect the layman will use grouting, thereby increasing the flooring cost. To avoid this, firm sort out tiles and lay on the floor and check before finally laying it permanently.

Error in Joints Due to Uneven Sizes of Tiles

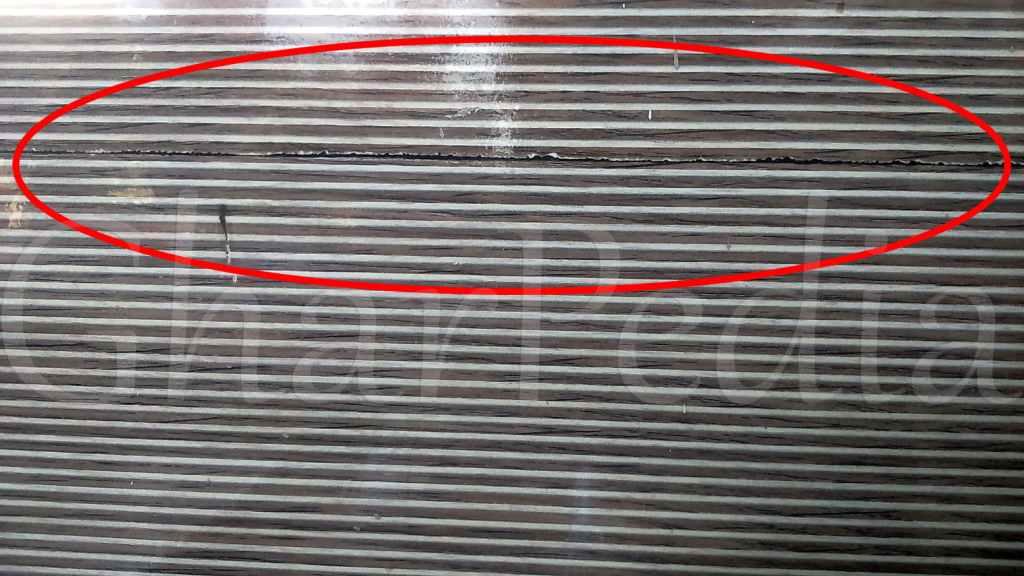

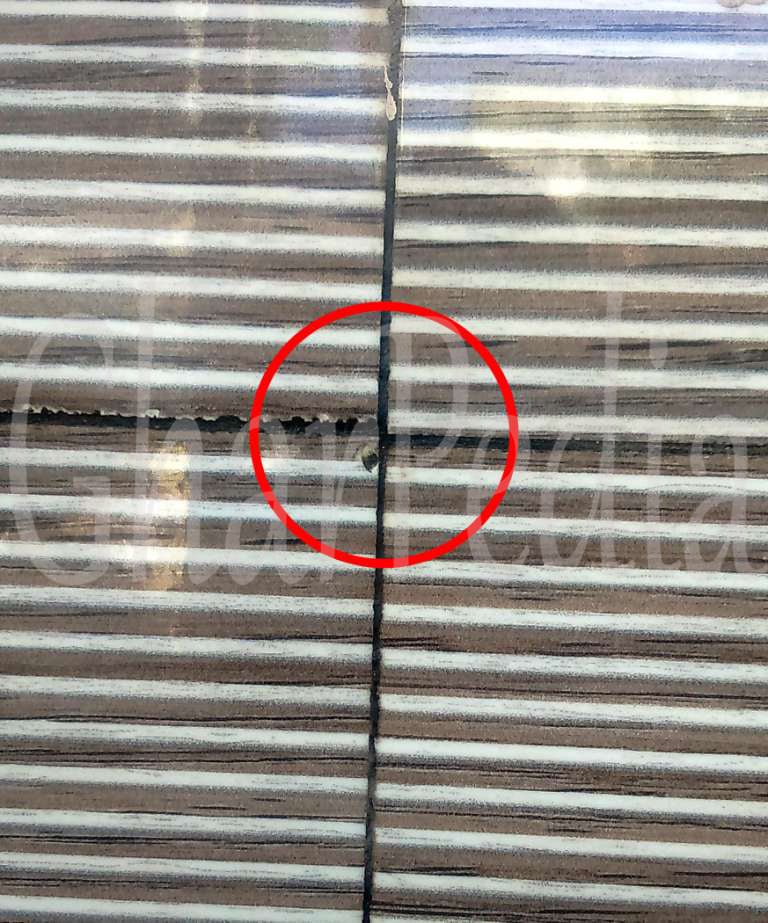

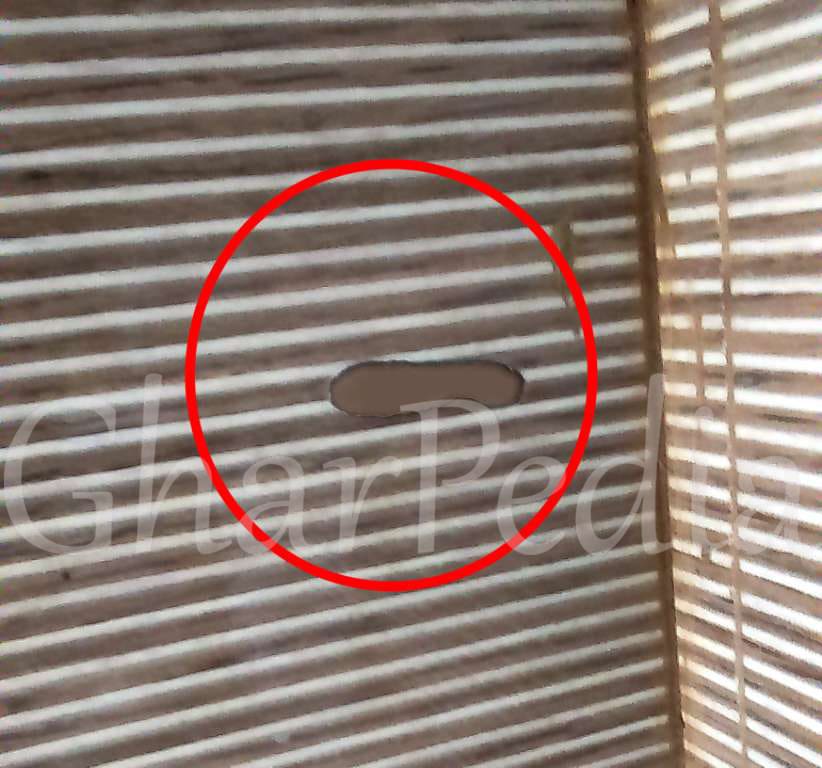

05. Surface Defects

Sometimes tiles have water drop marks on the surface called blobs and spots. Since vitrified tiles are machine-made, they may have machine marks. You may also observe other surface defects that generally look like holes of pin size called Pinholes or humps on surfaces called protuberances. It is necessary to have a spotless surface to sustain the aesthetics of the flooring.

Blob Defect

Pinhole

Surface Defects

06. Colour and Hue Defects

Vitrified tiles are processed in batches, according to order received or as per manufacturer cycle. Two batches will always have minor variation in processing time and composition, resulting in a colour variation. Make sure you order your tiles from a single batch to avoid having a colour defect.

07. Texture and Pattern Uniformity

Likewise colour defect these tiles may also have uneven textures. A single tile may have a dense texture at one end and sparse texture at another. A tile may have a blurry or faded pattern, which mark the look of it. One rarely observes such defects nowadays as technologies have improved immensely.

08. Defect in Finishing

Vitrified tiles come in different finishes like glossy, satin and matt. These finishes are achieved by polishing it by a durable coating. Uneven polishing may create an irregular surface and feel.

Courtesy - markstraley.com

Hence, in brief, checking these defects in vitrified tiles is as important as selecting a designer tile.

For that, we would recommend to randomly check 4 to 5 tiles from different boxes, manufactured from a single batch. If 95% of tiles pass the defect test, you may go ahead with your order. So, now on, do make sure your money is worth spending on the good quality of vitrified tiles.

Also Read:

Causes of Rust Stains on Tiles

Ceramic Tiles vs Vitrified Tiles – How to Make the Right Choice

Floor or Wall Tiles – Defects and Solution

Author Bio

Urnit Kaur – Urnit Kaur is an Architect based in Ahmedabad. She loves Design challenges and it helps her client’s to bring their thoughts into reality. She has been passionately involved in Architecture from designing projects to managing them on site since 2014. She has been part of Ahmedabad Heritage Dossier project, designing ISRO Bopal campus and currently working on other varied scale projects with Aakruti Architects. With her rich experience in field work, she shares tips and facts in her blogs about Architecture, Interior and MEP services. She believes learning should never stop, so she has developed a hobby of creating colorful home décor items by experimenting different materials and aesthetics.