Concrete compaction is also known as consolidation of concrete which is used to get highest density of concrete. Historically, it was achieved by ramming or punning, but nowadays compaction is mostly carried out by vibration.

Air bubbles develop when the fresh concrete is poured in the form. If we do not eliminate air bubbles from the concrete mix then concrete becomes porous or permeable. Porous or permeable concrete leads to the problems like leakages, corrosion, etc. in house or building. Compaction or consolidation is a technique, which has the effect of fluidifying the mortar component of the concrete mix so that internal friction reduces and packing of coarse aggregates take place. The technique eliminates most of the entrapped air bubbles from the fresh concrete. It helps to achieve the designed strength of concrete and ultimately increases the service life of the house or building.

Methods of Compaction of Concrete

The main purpose of compaction of concrete is to get the dense mass of concrete without voids. Compaction also helps to get the concrete to surround all the reinforcement steel and to fill all corners of the form, however small they may be.

Compaction should be applied uniformly to the entire concrete mass. If concrete is well compacted, we achieve durable concrete, but over compaction also leads to the segregation of concrete.

Methods of Compaction of Concrete

Following are the different methods of compaction of concrete, which are given below.

01. Manual Compaction(Hand Compaction)

Manual compaction is also known as hand compaction, which is carried out by rodding ramming or tamping the concrete, with either a bamboo or steel rod.

Rodding for Concrete Compaction:

Rodding for Concrete Compaction – Hand – Manual Compaction

Rodding is adopted for small placements or unimportant concrete work. In rodding, generally, we tamp a steel rod for the compaction of concrete. We can also use a flat-nosed spade for the compaction of concrete. It is effective with higher slump concrete.

It is not advisable to compact the concrete of RCC wall or RCC column by rodding.

Rodding is used to compact the corners and edges of the concrete cubes. It is also used to compact the precast concrete blocks.

Ramming for Concrete Compaction:

Ramming for Concrete Compaction – Hand – Manual Compaction

Image Courtesy – Restuccia Excavating

Ramming can be carried out in unreinforced foundation concrete or in small works (ground floor construction). Concrete should be rammed or puddled to force out the entrapped air bubbles at the time of placing of concrete. Ramming of concrete depends upon the concrete slump. If the slump of concrete (water-cement ratio) is high, the aggregates settle down at bottom and cement slurry may appear at the top layer. It may result in poor strength of concrete that may lower the service life of house or building.

Tamping for Concrete Compaction:

Tamping for Concrete Compaction – Hand – Manual Compaction

Courtesy - Tiny House Cabins Ltd

Tamping is adopted to compact the roof or floor slab or pavements of RCC road where the thickness of concrete is comparatively less and the surface is to be finished smooth and level. It is done with the wooden cross beam (generally size of beam is about 10 x 10 cm).

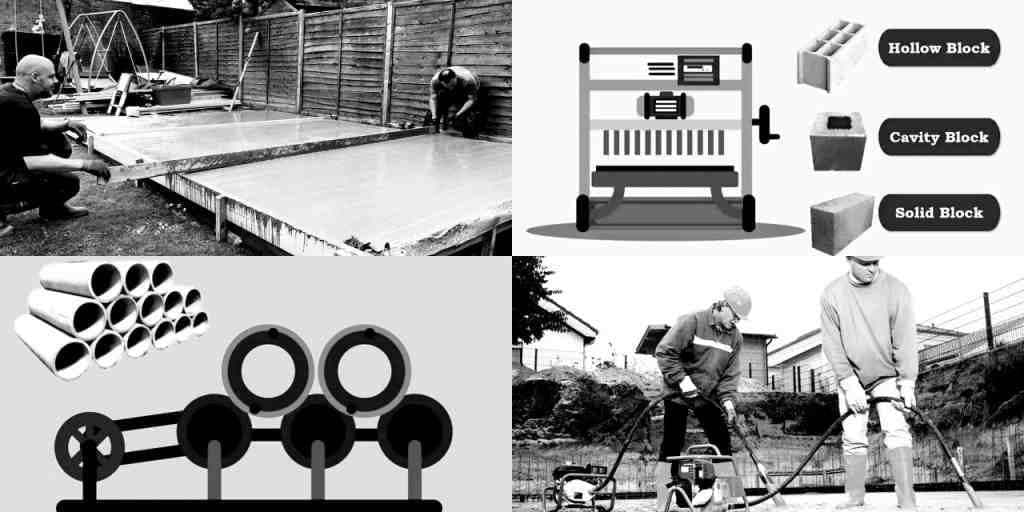

02. Concrete Compaction by Pressure and Jolting

This compaction method is used for compacting hollow blocks, cavity blocks, concrete blocks. In this method, the stiff concrete is vibrated, pressed, and also given jolts.

Watch Video: Compaction of Concrete by Pressure and Jolting

03. Concrete Compaction by Spinning

This method is used for compacting the concrete pipes (RCC Hume Pipe). In this method, the fresh concrete is well compacted by centrifugal force which is generated while spinning process.

Watch Video: Concrete Compaction by Spinning

04. Mechanical Compaction by Vibration

Mechanical compaction is carried out by vibration.

Following are the types of vibrators which are used to compact the concrete by mechanical means.

Types of Vibrators for Concrete Compaction

Internal Vibrator for Concrete Compaction

Internal Vibrators are also known as Needle Vibrators or Immersion Vibrators. They are commonly used for the large works whose surfaces are flat i.e. floor slab, Roof slab, RCC footing, RCC raft, column, etc. The vibrator is kept immersed in one location till the surrounding concrete is consolidated completely. Compaction can be judged visually by the formation of a circular shaped laitance around the niddle. Depending upon the consistency of the concrete mix, niddle (poker) is applied at 0.5 to 1m (2 to 3 feet) centre to centre for 5 to 30 seconds. It is advisable to have stiff concrete mix. The time of vibration at one location should not be less than 90 seconds.

Two types of internal vibrators are available in the market.

(a) Flexible shaft type internal vibrator

Flexible shaft type may be operated by compressed air or motor or gasoline engine.

Flexible Shaft Type Internal Vibrator

(b) Motor in Hand Type Internal Vibrator

Motor in hand type can be operated either electrically or pneumatically.

Motor in Hand Type Internal Vibrator

Image Courtesy – Bosch

Internal vibrators are well-known and it is the most common type of vibrator. Internal vibrator consists essentially of a poker (metal rod type vibrating head), housing an eccentric shaft driven through a flexible drive from a mortar.

Formwork Vibrator (External Vibrator) for Concrete Compaction

Formwork Vibrator (External Vibrator) for Concrete Compaction

Image Courtesy – CONCRETE SERVICES & SUPPLIES LIMITED (CSS)

Formwork Vibrators are also known as External Vibrators. External vibrators are jointed with the concrete formwork and vibrating force for compaction is conveyed to the concrete through the formwork. External vibrators are used mostly for the precast concrete and thin section of concrete (whose thickness is up to 600mm) or in the situation where internal vibrators cannot be used with ease.

Concreting should be done in layers of suitable depth. The height of concrete pouring should not more than 750mm in layer and if it is greater than 750mm, the position of vibrator should be changed or the series of vibrators should be used.

Roller vibrator, turbine vibrator and electric hammer are also other types of external vibrators.

Electric hammer is one of the vibrators which is used for compaction of concrete test specimens.

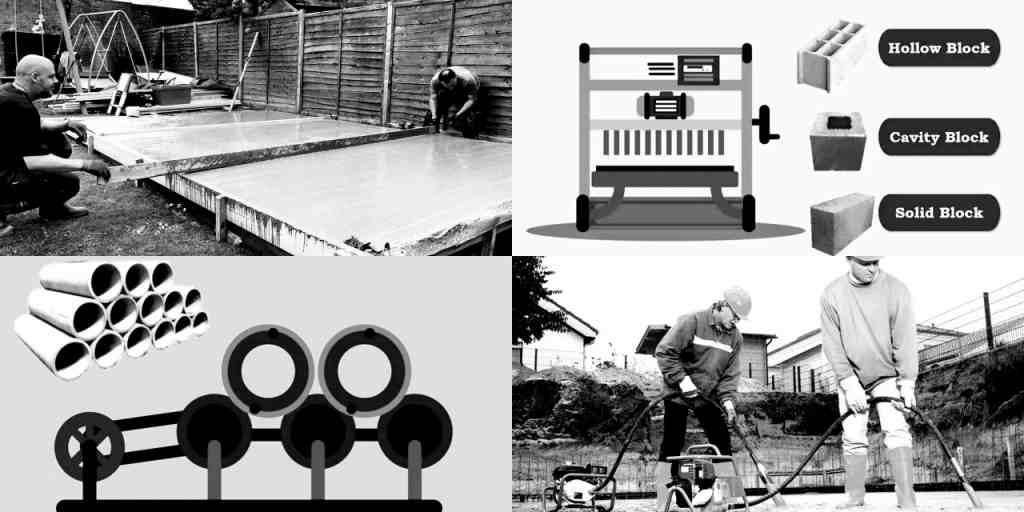

Table Vibrator for Concrete Compaction

Table Vibrator for Concrete Compaction

Image Courtesy – Star Trace Pvt. Ltd

In case of the Table Vibrator, the formwork is clamped to the steel platform which is mounted on the flexible spring. Generally, a rapidly rotating eccentric mass makes the table vibrate with a circular motion. With two shafts rotating in opposite directions, the horizontal component of vibration can be neutralized so that the table is subjected to simple harmonic motion in the vertical direction only. Some table vibrators are operated by an electro-magnet fed with alternating current. The range of frequencies used varies between 50 and about 120 Hz. An acceleration of about 4g to 7g is desirable for compaction of concrete. Variable frequency of vibration is an added advantage.

A vibrating table provides a reliable means of compaction for precast concrete and has the advantage of offering uniform compaction.

Following are the advantages of table vibrator:

- Leaner mix of concrete can be used to achieve the same strength. Hence it results in saving cement up to 10 to 15 % and better strength.

- It permits compaction of narrow or thin sections where hand compaction may be difficult.

- The resultant concrete is more impermeable, dense, and free from honeycombing.

- Compaction is faster which results in economy in time and labour.

Sometimes shock table is used for the manufacturing of precast concrete. Vibrating with shock table gives extremely good results but the process is rather specialized and not widely used.

Platform Vibrator for Concrete Compaction

Platform Vibrator for Concrete Compaction

Image Courtesy – Hijoy

Platform vibrator is one kind of table vibrator which is comparatively large in size. Platform vibrator is used in the manufacturing of large precast section i.e. electric poles, railway sleepers, etc.

Surface Vibrator (Screed Vibrator) for Concrete Compaction

Surface Vibrator (Screed Vibrator) for Concrete Compaction

Image Courtesy – wikipedia

The surface vibrator is also known as screed vibrator. Surface vibrators are mounted on platforms or concrete screeds and are generally used to compact and finish the bridge floors, road slabs, etc.

Vibratory Roller for Concrete Compaction

Vibratory Roller for Concrete Compaction

Image Courtesy – worldhighways

Nowadays dry concrete and lean concrete are compacted by using the vibratory roller. Hence, this type of concrete is also known as Roller Compacted Concrete or Rolled Concrete.

Repair and maintenance troubles may occur in the house or building due to bad practices in concrete construction. Hence, always follow good construction practices i.e. using a proper method of compaction of concrete to make durable concrete. It helps you to reduce the repair maintenance cost of your house or building. It is advisable to use internal vibrator or needle vibrator for the compaction of concrete while you build a house. It helps you to achieve a good quality concrete throughout the construction work.

Must Read:

Do’s and Don’ts while Concreting

What Materials are Used to Make Concrete?

What is Concrete Mix Design?

Weigh Batching vs Volmetric Batching