In plumbing, a trap is a device shaped with a bending pipe path to the retain fluid to prevent sewer gases from entering building while allowing waste materials to pass through. In domestic applications, traps are typically U, S, Q, or J – shaped pipe located below or with in a plumbing fixture. The most common of these traps are referred to as a P trap.

Plumbing is a work that is mainly related to, supply of water and disposal of sewage. The plumbing system shall remain odourless provided, it is designed skillfully and installed decently.

Sewage is a waste water which itself produces foul gases. The gases include methane, carbon monoxides and sulphide, which are unsafe to health and sometimes fatal. We cannot stop the process of producing the foul gases from the waste, but we can definitely stop the entry of such gases into the house. Sewer gases sometimes prove fatal and can bring minor illness. Here comes the role of plumbing traps.

The trap can be defined as fittings at the end of soil pipes or waste pipes to stop foul gases (odour) coming out of these soil pipe or waste pipe. It means, it maintains the water seal inside it and block the entering passage of foul or unhealthy gases.

As stated in Plumbing Engineering – (Theory, Design and Practice) by ‘Prof. Subhash M. Patil’, water seal is a designed water barrier that is provided in the trap to prevent the air from passing out of the waste pipe and into the room. i.e. it keeps few inches of water between house air and sewer air.

Role of Plumbing Traps

Plumbing trap is a part of the drainage system. It is developed or designed in such a way that it retains a small quantity of waste water from the discharge, of fitting to which it is attached, as a barrier to prevent foul gases or air entering in the building.

Plumbing traps are an important component of the sewage system. They prevent entry of foul air, insects and parasites from the sewers into the building and resist the spread of diseases. Traps are constructed, so that they retain a body of water which acts as a water seal.

Traps should be of the self-cleaning type. They should generate enough speed from the available flow to create a self-cleansing effect, i.e. a smooth finish and a full identical opening.

As our mentor Shri Mahadev Desai says “from experience of 45 years of my professional life, I would say that, maintaining the water seal is critical to trap operation; Traps might dry-out, and poor venting can suction or below water out of the traps. This is usually avoided by venting the drain pipes downstream of the trap; by being vented to the atmosphere outside the building, the drain lines never operate at a pressure much higher or lower than atmospheric pressure”.

Some manufactured fixtures, e.g. water closets, bed pan washers and certain models of urinals have integral traps, built within the body of the fixture.

Water closets and in some cases, urinals are provided with integral traps. All other fixtures shall be provided with external traps with adequate water seal. Diameter of the trap shall in no case be smaller than the diameter of the outlet of the fixture, to which it is connected.

Traps should be of self-cleansing design with uniform bore and shall not be dependent on internal partitions or other movable parts for retention of water seal. Connection of a trap into another trap should not be practiced. Diameter of outlet pipe from a floor trap shall not be less than the size of the trap outlet.

Different Types of Traps

Different types of Traps are as follow:

01. Floor Trap or Nahni Trap

- Floor trap or Nahni trap is provided in to the floor to collect waste water from bathroom, wash area, washbasin, and kitchen sink area etc.

- It is normally made in 80 mm diameter and the depth of water seal provided is about 50 mm.

To know more read: What is Floor Trap or Nahni Trap?

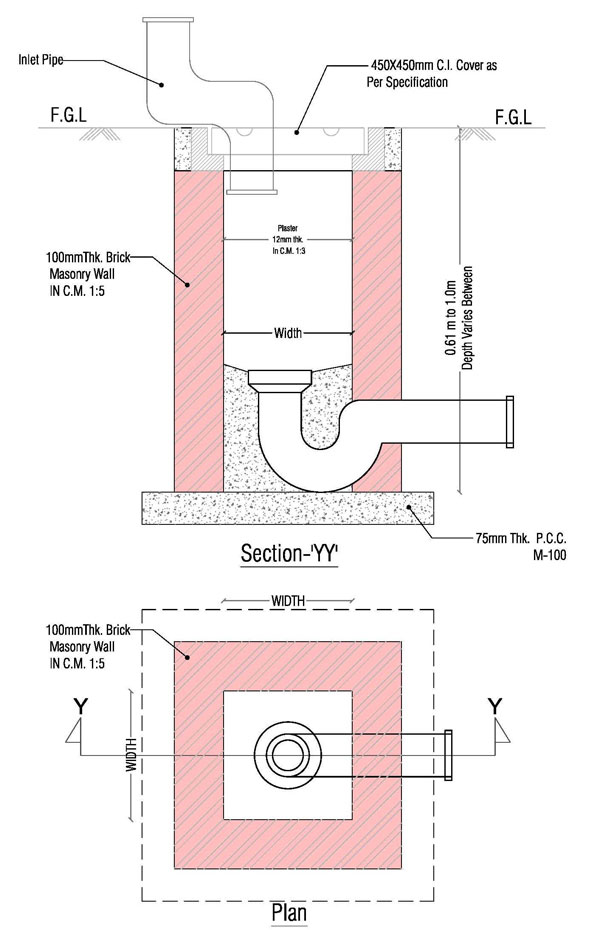

02. Gully Trap

- A gully trap is provided outside the building before connecting it to external sewerage line. It also collects waste water from the kitchen sink, wash basins, bath and wash area.

- As stated in Practical Handbook on Public Health Engineering by ‘Er. G S BAJWA’ (Former Executive Engineer, Shimla), the heavy cast iron gully traps shall not be less than 7.25 KG (16 lbs) in weight with cover weighing not less than 4.53 kg and frame not less than 2.72 kg and total depth shall not be less than 30 cm (1 ft). To know more read: What is a Gully Trap?

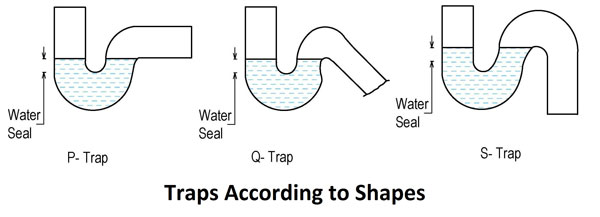

03. P, Q and S-Trap

- P, Q, and S traps are classified according to their shape. They essentially consist of U – Tube which retains water acting as seal between the foul gas and atmosphere.

04. Intercepting Trap

- Intercepting trap is provided in to the Interceptor Manhole (Interceptor Chamber). An Interceptor manhole is provided at the interception of building sewer and Public sewer. Intercepting trap is provided to prevent the foul gases from public sewers entering in to the building sewer by providing water seal. To know more Read: What is Intercepting trap?

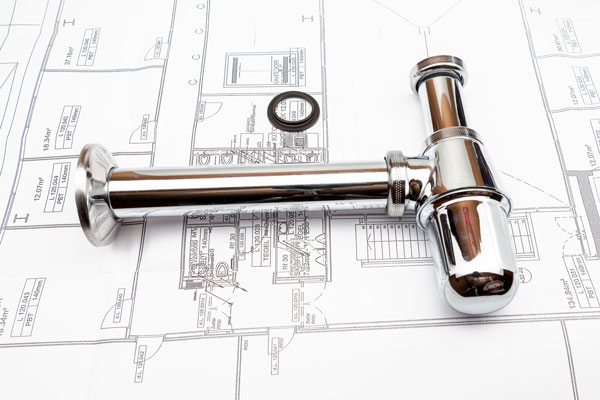

05. Bottle Trap

- A bottle trap is provided to receive waste from washbasin, kitchen sinks and other appliances where the appliances do not have a built-in trap.

06. Grease Trap

- Grease trap is installed in the waste pipe from one or more fixtures for the purpose of separating grease from the liquid and retaining the grease.

There are other plumbing traps like crown vented P traps, full S traps, Q traps, etc. that are not used nowadays by plumbing experts.

Traps normally would not lose its seal unless it is not designed properly or there are no vents or due to the evaporation of water from the traps.

Traps installed in the areas, not in normal use, may lose their water seal due to evaporation. Provisions must be made to renew the seal by adding water periodically and this can be done by connecting a waste appliance to the trap (e.g. a wash basin, etc.). Replenishment is also achieved by installing a sophisticated water supply valve with a back-flow prevention device, which is connected to the trap.

Care has to be taken to prevent installation of traps that are exposed to freezing conditions. Thus, the traps are most useful device to save ourselves not only from the odour of foul gases but also from the fatal effects of these poisonous gases.

Different Types of Pest Removal Traps

There are various repellents and traps available to rid your home of rodents and other creatures, and each method has its advantages as well as disadvantages. The most common type of traps are Electronic Traps, Ultra sonic Rodent Repellents, Snap Traps, and Glue Traps.

Summary

In brief, there are different types of traps in Plumbing: Floor Trap or Nahni Trap, Gully Trap, P Trap, Q Trap, S Trap, Intercepting Trap, Bottle Trap, Grease Trap. They are available in different materials like PVC, GI, etc.

Aforementioned types of traps are widely used in plumbing work but an ideal plumbing traps have following features or benefits:

- Resistance to the impact damage and house hold chemical

- Prevent entry of foul air, insects and parasites from the sewers

- Anti-rodent and self-cleaning

- Long service life

- Easier and quick installation

- Economical

If you want your house free from foul odour, insects and parasites, do use the suitable and best quality of plumbing traps. This is not only easily and comfortably installed but it brings less weight on your pocket too.

Must Read:

The Complete Guide to Various Types of Valves in Plumbing Systems

Most Useful Plumbing Tools for Plumbing Project and Repair

Hire A Plumber | 10 Tips to Choose the Right Plumber for your House!

Image Courtesy: Image 7