Table of Contents

Quick Summary

- The dry process for cement manufacturing is the most widely used and energy-efficient method.

- Raw materials are first crushed, dried, and ground into a fine powder called raw meal.

- The raw meal is blended, preheated, and then heated in a rotary kiln at about 1450°C to form clinker.

- Clinker is cooled, mixed with gypsum, and ground to produce the final cement.

- The process consumes about 100 kg of coal per ton of cement, nearly 50% less fuel than the wet process.

- It offers better heat efficiency, smaller equipment size, and superior quality control.

- The dry process reduces CO₂ emissions, making it more sustainable and environmentally friendly.

- Despite higher setup costs, it remains the preferred process in modern cement manufacturing due to its efficiency and product quality.

Cement is a versatile and widely used construction material. It is composed of base materials, like limestone and clay, and produced in cement plants through a complex and energy-intensive process. However, advancements in technology have reduced energy consumption to a greater extent by adopting the dry process for cement manufacturing.

In this blog, Gharpedia simplifies the dry process of cement manufacturing to help you understand it better and choose the best cement, which has excellent binding properties and is produced through an energy-efficient manufacturing process.

Dry-Process Cement Production

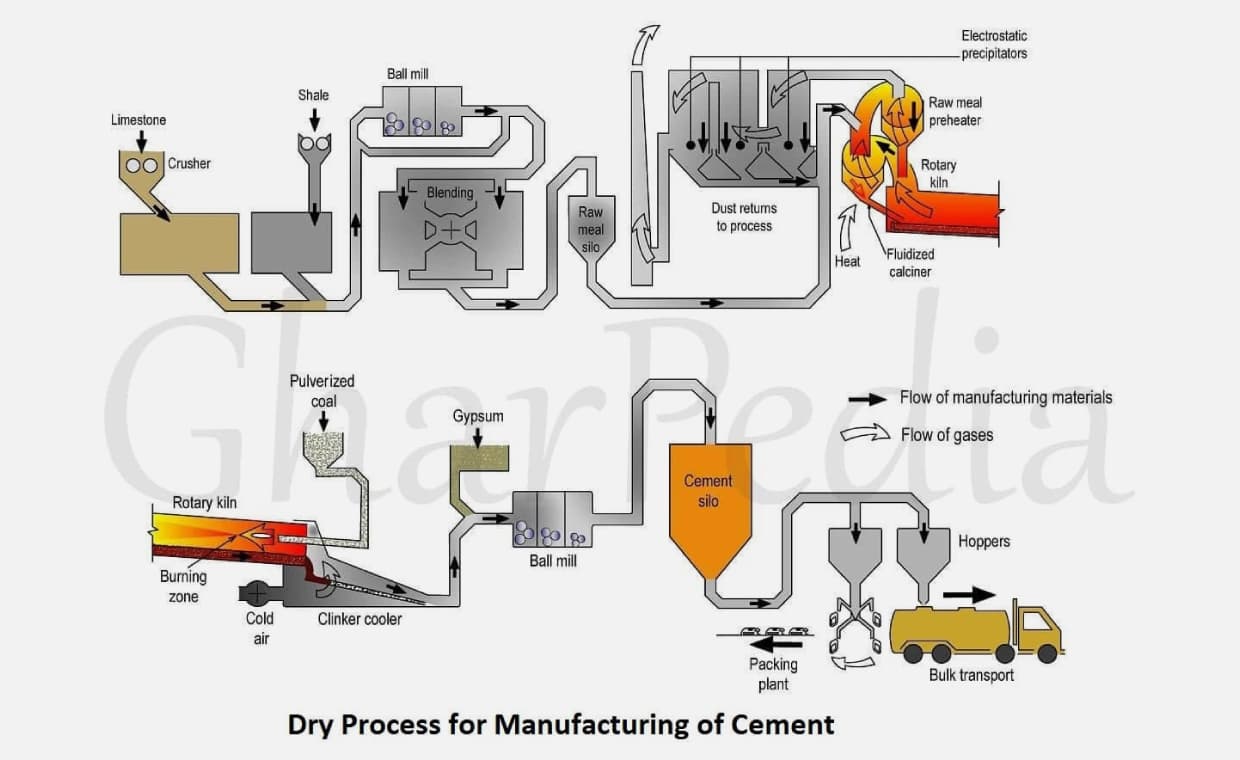

1. Extraction of Raw Materials – Cement is a mixture of argillaceous and calcareous materials. These materials are carefully extracted from quarries and crushed into smaller pieces using crushers.

2. Drying and Grinding – The crushed raw materials are proportionated and then fed into a grinding mill for drying and grinding. The dried and grounded to fine powder is known as ‘raw meal’.

3. Blending and Homogenization – These processes take place in blending silos where compressed air is passed through the raw meal to ensure a uniform and intimate mixture. The air induces an upward movement of the powder, decreasing its apparent density. Repeating this process in different quadrants of the silo for about an hour gives a homogenous blend.

4. Preheating – The raw meal is preheated in a preheater tower using the hot gases from the kiln. Heating of raw meal removes the moisture content and decomposes any matter left in it.

5. Clinker Production – This process takes place in a rotary kiln. Here, the preheated raw meal is heated to high temperatures around 1450 °C, where materials undergo several chemical reactions, forming clinker nodules (small dark grey balls) of about 3-25mm in diameter.

6. Clinker Cooling – The clinker is cooled using air or water in a rotary cooler. Rapid cooling of clinker retains its crystal structure and minimise the formation of undesirable phases.

7. Grinding – The cooled clinker is finely ground in a ball mill and 3 – 5% gypsum is added to attain desired fineness. The final product cement is ready here and stored in silos before packing.

8. Packaging – Cement is packed in bags which are delivered to construction sites for various construction applications.

Advantages of Dry Process for Manufacturing Cement

- Low fuel consumption – about 100 kg of coal per ton of cement

- Smaller equipment size, which reduces initial investment

- Higher heat efficiency, as no water needs to be evaporated

- Better quality control of the clinker and final cement

- Reduced CO₂ emissions, making it more eco-friendly

FAQs on Dry Process of Cement Manufacturing

01. What is the dry process for manufacturing cement?

Manufacturing cement involves crushing of raw materials, mixing and grinding them, preheating, clinker formation, cooling, and grinding of clinkers to fine powder. The dry process for manufacturing cement follows all these steps , except that water is not added during mixing and grinding. Instead, compressed air is used to create a uniform mixture.

02. How is the dry process different from the wet process of cement manufacturing?

In the dry process of cement manufacturing, water is not added during the mixing and grinding of raw materials, whereas in the wet process, water is added into the grinding mill at the time of mixing and grinding of raw materials to for a slurry before further processing.

03. What is clinker in cement production process?

Clinker is a hard, nodular material produced in the kiln during the cement manufacturing process. It consists mainly of calcium silicates and aluminates formed by chemical reactions at high temperatures. Clinker is the main ingredient of cement, and its quality determines the strength and durability of the final product.

04. Why is dry cement manufacturing process efficient over wet?

The dry cement manufacturing process requires less energy compared to the wet process, because in the dry process, the mixture is in dry form, unlike the slurry in the wet process. The dry mixture requires less heat in the preheating stage compared to wet process. Hence, dry process is energy efficient.

05. What are the disadvantages of the dry cement manufacturing process?

- The dry process requires sophisticated equipment, which increases the initial investment costs.

- In the dry process, a significant amount of dust is generated during the grinding and mixing stage. This poses environmental and health threats.