Concrete is one of the most essential components in building construction. The durability and life of a modern concrete structure depend on the quality of the concrete, which in turn depends heavily on the quality of the cement used to make it. If the cement is not stored in a moisture-free environment, it can be compromised. Hence, it makes you wonder: what is the effect of moisture on cement bags? Gharpedia provides a simple explanation of the effect of moisture on cement bags in this article.

Since the last few decades, cement consumption has been increasing day by day, and hence the production of cement is also increasing. According to the Bureau of Energy Efficiency, the per capita cement consumption in the world averages 500 kg per year. According to a report by the India Brand Equity Foundation in 2018, the percentage share of cement demand was 65% in housing and real estate, 20% in public infrastructure, and 15% in industrial development.

Most people need clarification while working with old cement or cement that has been stored for an extended period. For example, when they feel how hard it is, the next question that comes to mind is how moisture affects the cement. Before we discuss the effects of moisture on cement, let us understand the chemistry of strength gain due to cement.

Strength Gain in Cement

When mixed with water, cement undergoes a chemical reaction called hydration, due to which it hardens and acquires strength. This forms a major part of concrete’s strength. The finer the cement, the more it hydrates (i.e., mixes with water) and gains strength. Hence, when stored or not in use, even the atmospheric moisture reacts with the cement and causes it to harden. Thus, unwanted moisture is very dangerous for cement before use.

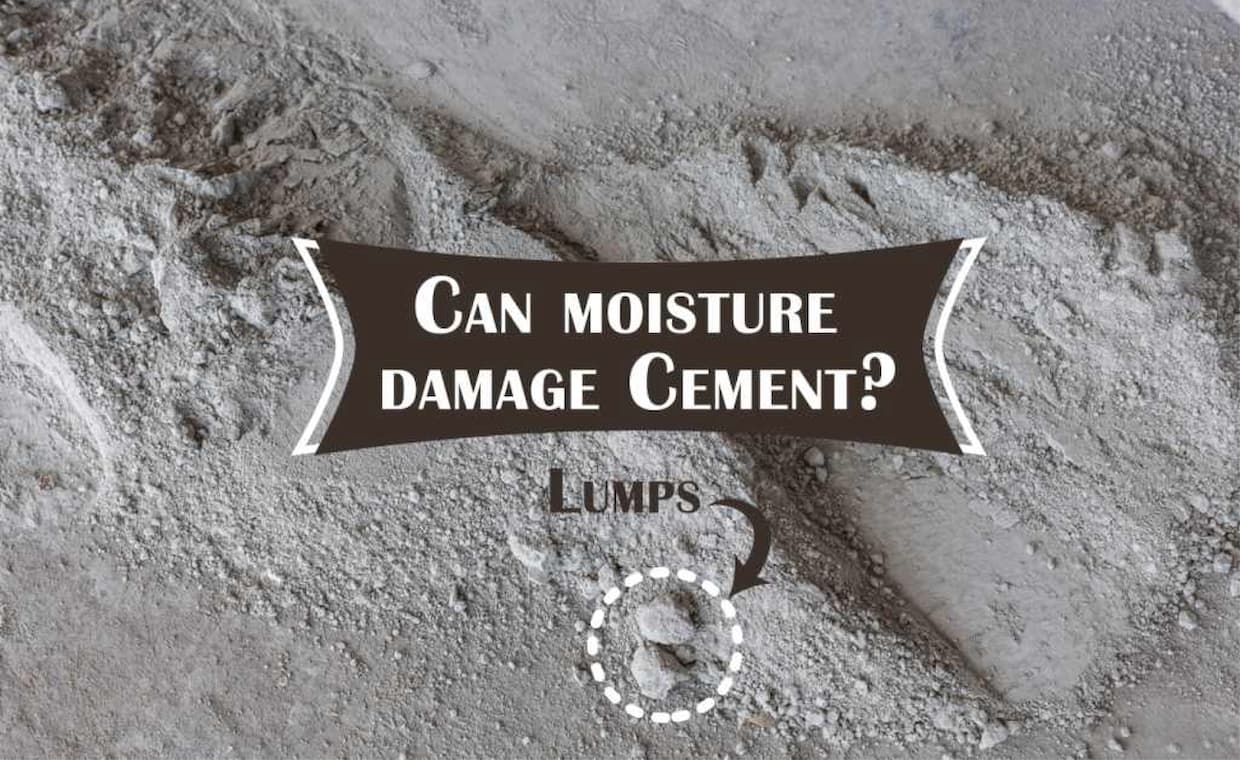

The manufacturing of cement includes a number of raw materials like lime, silica, alumina and iron oxide. There are two methods used to manufacture cement. Whether it is a wet process of manufacturing cement or a dry process of manufacturing cement, in both cases, moisture plays a key role before and after packaging. During the manufacturing of cement, if we do not control moisture and temperature, the produced cement will be of low quality. Similarly, if cement gets moist after packing, it forms lumps, and using such cement may result in poor-quality concrete or mortar, reducing the life of the building or house. Bagged hardened cement cannot be used in construction.

What is the Effect of Moisture on Cement Bags?

Cement, like sugar, is a hygroscopic material that reacts with water in liquid or vapour form. Cement in bags must be kept away from both wetness (leaks, flooding, etc.) and dampness (moisture in the air that cannot be seen). Moisture is a great enemy of cement.

When water vapour passes through the multi-layer paper, jute or polyethene sacks, cement gets hardened, forming lumps that damage the quality of the stored cement. Hence, cement should be stored in such a manner that no moisture or dampness is allowed to reach it, either from the ground or from the environment. Extra precautions should be taken on-site and in a warehouse while storing cement. The godown and warehouse should be leakage-proof and built at a higher elevation so that they will not be affected by moisture. We have a detailed guide on how cement bags must be stored:

Cement plays a crucial role in binding the dry ingredients of concrete or mortar when water is mixed and in giving concrete its strength. Cement and water react with each other and generate the heat of hydration. This process of generating heat is also known as “the hydration of cement”. Due to the initial setting of the cement, the concrete/mortar mix starts to harden within the initial setting time. When water is added, the cement sets. The initial setting takes place in 30 minutes.

After the initial setting, the cement hardens, which makes it non-reusable. Similarly, if cement stored in bags is exposed to moisture, it will react with it and harden into lumps. Then the question arises: Can you use cement that has hardened in the bag? Such cement will have poor performance and hence should not be used.

As a result, cement bags, like food, should not be stored for long periods of time and should be used as soon as possible after manufacturing. It is recommended that freshly manufactured cement be used within the first three months to ensure good concrete quality. If the cement has been stored for more than three months, it should first be tested for quality, and only then should it be used for construction.

In conclusion, the strength and durability of the structure are primarily determined by the strength of the cement It is, therefore, essential to use fresh cement of good quality. The quality of cement remains good only if the effects of moisture on cement bags are minimal or negligible. Hence, cement bags should be used as soon as possible. The cement bags should be stored in a dry, enclosed structure protected from rain and moisture, and the stacked bags should be covered with waterproof sheets or tarpaulin.

Before leaving, make sure to check our other articles on cement:

11 Points That You Should Always Check on a Cement Bag Before Buying It!

How to Check the Quality of Cement at Site?