Workability of concrete is the most important and a complex property of any fresh concrete. Workability directly affects the strength and quality of the concrete. It indicates how easily the concreting process can be done i.e. mixing, placing, compacting and finishing with minimum or no loss of relative homogeneity.

There are many factors affecting the workability of fresh concrete; hence it is necessary to measure workability of concrete, before or during the concreting work. There are assorted sources available for testing such as slump test, compaction factor test, flow test, vee bee consistometer test, kelly ball test etc. Here we have discussed the flow test of concrete, its testing apparatus, procedure, result etc.

What is Flow Test of Concrete?

The flow test is performed to measure workability of concrete. As name suggests, in this test the workability of concrete is measured by examining the flowing property of concrete. The flow test is a simple laboratory test. This test works on the principal of a jolting of the standard mass of concrete and measured by flow of concrete. The flow of concrete indicates the workability of the fresh concrete.

Why Flow Test of Concrete is Required?

The flow test is used to measure the workability of high or very high workable concrete, which eventually would exhibit the collapse of slump. It gives an idea about the quality of the concrete with respect to the consistency and cohesiveness. This workability test is quite simple to perform and is the best for the concrete which has a nominal maximum size of aggregate less than 38 mm.

Is there any Relationship Between the Concrete Slump Test & Flow Test?

Multiple laboratory experiments are performed to find out the relation between the concrete slump test and flow test. Some researchers have also shown a linear relationship between the two in their particular experiments (research). But according to ‘A. M. Neville’, honorary member of the American Concrete Institute, both tests do not measure the same physical phenomena; hence, there is no relation between the slump test and flow test.

Standard Guidelines for Flow Test

There are various standard guidelines available to perform the flow test. Such as,

- IS 1199 – 1959

- ASTM C 124 – 39 (Reapproved 1966)

- BS 1881 :105: 1984

We have discussed below, the flow test apparatus, procedure and calculation as per the ‘Indian Standard, IS: 1199- 1959’.

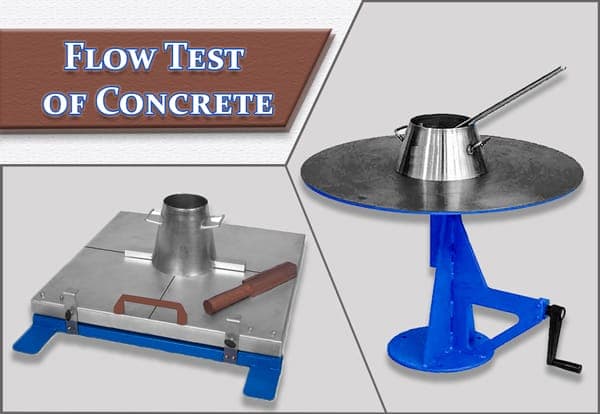

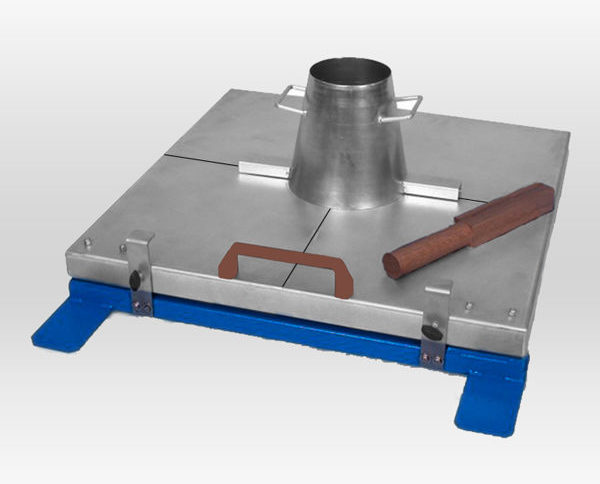

Flow Test Apparatus

- Metal Cone or Mould: Mould is in the form of a frustum of a cone with a base diameter of 250 mm, upper surface diameter of 170 mm and 120 mm height. The mould comes with handles for support.

- Flow Table

- Trowels

- Hand scoop

- Scale

- Tamping Rod

Flow Test Apparatus

Flow Test Procedure

- Clean all the gritty material or dust from the flow table and from inside the mould.

- Place the cone in the marked or middle portion of the flow table.

- Now pour the freshly mixed concrete in the mould in two layers, each layer should be tamped 25 times with tamping rod. If concrete overflows after tamping then level it with the help of a trowel, and excess concrete should be removed off from the table.

- Then, lift the mould vertically upward and let the concrete stand on its own without support.

- Thereafter the table is raised and dropped from 12.5 mm height, 15 times in about 15 seconds.

- Next, measure the diameter of the spread of concrete in about 6 directions and note down the average.

Result Calculation

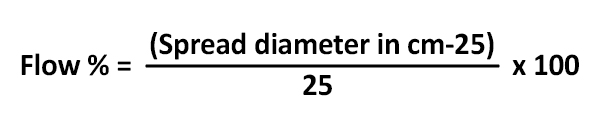

The flow of concrete: The percentage increase in the average diameter of the spreading concrete over the base diameter of the mould is called the flow of concrete.

Formula for Measuring Concrete Flow

Recommended Result of Flow Test

The value of flow test should be in range of 0 to 150 %.

Another test which is similar to the flow test is known as flow table test. It was developed in Germany in 1993, and this is covered by the BS 1881 :105: 1984. In this Flow table test, manual flow table is used which is 700 sq. mm in area, made by wooden board covered with a steel plate. For placing the metal cone on the middle of the flow table, circle of 200 mm diameter is marked. This board is hinged on one side to a baseboard and upper board. So that board can be lifted upward to free fall.

Flow Table Test Apparatus

One metal cone or mould is placed at the center of the board which has a bottom diameter of 200 mm, top diameter of 130 mm and 200 mm height and concrete is poured in it. After the pouring, lift the mould vertically and let the concrete stand on its own. When concrete flows, measure the flow in two directions, i.e. vertically and horizontally. Average value of these two diameters is indicating the flow of concrete in mm.

According to ‘A.M. Neville, honorary member of the American Concrete Institute’, this flow table test is appropriate for concrete mixes having a flow of 340 to 600 mm.

Summing up, High workability of concrete is needed where limited vibration or compaction is possible, in hot weather concreting, in the construction of highly congested reinforced elements etc. This flow test of concrete is very helpful for measuring high or very high workability at such locations.

Also Read:

Nominal Mix and Design Mix of Concrete: Know the Difference

Cube Test to Check the Compressive Strength of Concrete

Field vs Laboratory Testing of Cement