Workability of concrete is the essential property of fresh concrete. Workability of concrete means the ease of working with concrete.

Concreting includes following process:

- Concrete Mixing

- Concrete Transportation

- Concrete Placing

- Concrete Compaction

- Finishing with the homogeneity

It is necessary to measure workability of concrete before and during the concreting work because many factors affect the workability of fresh concrete like, weather conditions, type of work, types of ingredients which are used to make concrete etc. According to such factors, the requirement of workability like low workability, medium workability, high workability differs for each set of conditions.

Various methods are used to measure the workability of concrete. Following are the main test carried out in laboratory to check the workability.

- Slump Test

- Compaction Factor Test

- Flow Test

- Vee Bee Test

- Kelly Ball Test

Here we are discussing the vee bee test of concrete, its testing apparatus, procedure, result etc.

What is Vee Bee Test of Concrete?

Vee bee test is the pure laboratory test to measure workability of fresh concrete. Vee bee test is also called ‘Vee Bee Consistometer Test’, ‘Vebe Test’ etc. The name ‘vee bee or vebe’ is derived from the initials of V. Bahrner from Sweden, who developed this test. In the vee bee test, workability is measured with the aspect of mobility and compactibility.

As you know, the workability of fresh concrete is defined as the amount of useful internal work necessary to produce 100% compaction. Vee bee test gives the time required to achieve compaction, which is related to the total work done; hence vebe test is a good test to measure the workability of concrete indirectly.

In the vee bee consistometer test, the shape of concrete is changed from the slump cone shape to the cylindrical shape through the vibration process; this is called remoulding effect. This remoulding effect is measured in seconds which is called vee bee degree or vee bee seconds.

Vee bee consistometer test is suitable for very dry concrete whose slump value can’t be measured by slump test, but the vibration is too strong for the concrete where slump is greater than 50 mm, hence the remoulding activity can’t be measured or it is difficult to measure in seconds.

Standard Guidelines for Vee Bee Test

There are various standard guidelines available to perform the vebe test. Such as,

- IS 1199 – 1959

- ACI 211.3 – 75 (Revised 1987)

- BS EN 12350-3: 2009

Here, we have mentioned vee bee consistometer test as per the IS: 1199- 1959.

Vee Bee Consistometer Test Apparatus

Vee Bee Consistometer:

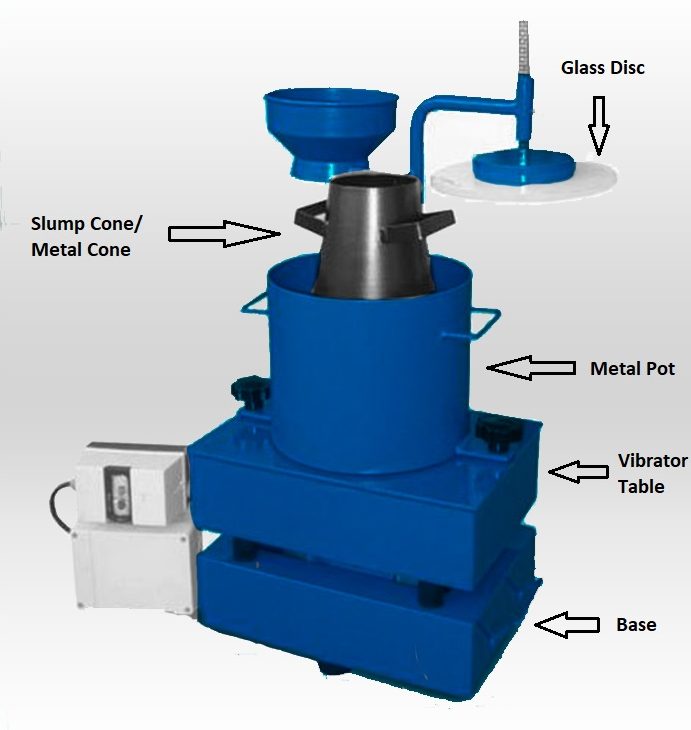

Vee bee consistometer is consist of the followings components.

- A vibrator table: The vibrating table is 380 mm long and 260 mm wide and is supported on rubber shock absorbers and mounted on a base.

- A metal pot or Cylindrical Container: The metal pot is fixed on to the vibrator table through two wing-nuts.

- A sheet metal cone or Slump Cone: The sheet metal cone is a slump cone which has 300 mm height and its bottom diameter is 200 mm and top diameter is 100 mm. It is placed in the metal pot

- A standard iron rod

- Stop Watch

Vee Bee Test Procedure

- Place a sheet metal cone/slump cone in the metal pot/cylindrical container of the consistometer.

- Fill the concrete in the slump cone in four layers; each layer should be one-quarter of the height of the slump cone. Tamp each layer with the rounded end of tamping rod for 25 strokes. After the last layer has been tamped than level the surface with a trowel.

- After the levelling of slump cone surface, move and place the transparent glass disc which is attached to swivel arm on the top surface of the slump cone in the metal pot and then note down the reading from the graduated scale as an initial reading.

- Now, remove the slump cone slowly and carefully in the upward direction and wait till the concrete settles in new position. Then lower the transparent glass disc on the top of the concrete and note down the reading from the graduated scale as a final reading.

- Determine the slump value by taking the difference between the final reading and initial reading, which are taken from the graduated rod.

- Now, switch on the vibrator and start the stopwatch allow concrete to spread out in the metal pot.

- The vibrator should be continued till the concrete surface completely adheres uniformly to the transparent glass disc.

- And note the time taken for this remoulding process. This time is recorded in seconds.

Result Calculation

Slump Value = Final Reading – Initial Reading: Slump value is the difference between the final reading and initial reading, which are taken from the graduated rod.

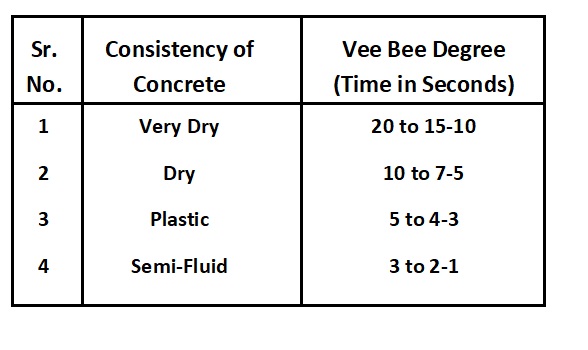

Vee Bee Degree: In the vee bee consistometer test, the shape of concrete is changed from the slump cone shape to the cylindrical shape in seconds, the required time to change the shape of concrete is known as vee bee degree.

Points to be Taken Care of

- Apparatus should be clean and free from moisture before starting the testing.

- Before pouring the concrete in the slump cone, the oil or another lubricant should be applied inside the cone.

- While strokes are applied in the slump cone at the time of filling the cone in the layers, strokes should be applied uniformly throughout the layer.

Recommended Result of Vee Bee Test

Vee bee test of concrete is more suitable for dry concrete than the other types of workability test such as slump test, flow test etc. and that is why it is mostly used for dry concrete or concrete with a low water-cement ratio.