In India, ceramic tile is commonly known as Spartek. Spartek was a company in India which was pioneer in manufacturing of ceramic tiles. It was one of the producers of ceramic tiles. This brand became so popular that people actually started knowing the product by their brand name itself like all toothpaste are known as Colgate and all adhesives as Fevicol.

Uses and Advantages of Ceramic Tile

Ceramic tile can be used in outdoor as well as indoor areas. Ceramic tile is the most suited to homes as they are very easy to clean. Ceramic tiles can be used for both floor tiles and wall tiles. It is extensively used as flooring and also as wall tiles to make decorative accents both inside and outside the houses. It is suitable in kitchen backsplashes and food counters as it is easy to clean and hence hygienic. Ceramic tiles are used as floor tiles in wet areas like a toilet, bathroom, etc.

Ceramic tile is available in different sizes, colours and shapes. The appearance of tile changes according to the variety of textures and colours applied during the manufacturing process. Various shapes like squares, rectangles and hexagons are available in the market. Ceramic tile flooring is cheaper than other types of flooring options like marble, granite, wooden flooring, etc.

Ceramic tile has different physical properties and advantages like water absorption, scratch resistance, stain resistance, frost resistance, etc. and also the colour of the glazed ceramic tile do not fade. Ceramic tile flooring is uncomfortable during cold climates. The size of the ceramic tile is usually less than 2ft ×2ft. The thickness of the tile is usually 6mm to 12mm. However, for wall tiles, less thickness should be used so that they do not fall due to weight. The more thickness will increase the weight of the tile.

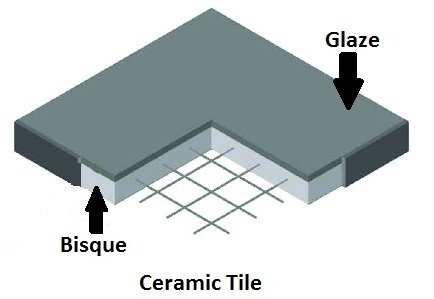

Ceramic tile mainly consists of two parts: the body which is called “Bisque” and the surface which is called “Glaze”. It can be glazed or unglazed.

Courtesy - knittingontrains

The ceramic tile is made by the mixture of clay and water only. The process involves moulding the clay into the shapes of tiles and then baking or burning them inside a kiln. The heat results into the hard structure of clays. Then the tiles are coated with the glaze so that they become water resistant.

Ceramic tile is applied on a solid backing by means of a mortar or adhesive. They are generally applied with the thinnest mortar joint, and therefore accuracy of dimensions is of greatest importance. The thickness of cement mortar should be 10mm to 12mm.

Ceramic tile installation needs to be done by skilled workers as it is heavy in weight.

The price ranges are approximately Rs .50-400/sq.ft. The price may vary from city to city and manufacturer to manufacturer and also as per their sizes.

While laying in a large area, proper joints should be allowed, otherwise, the tiles will pop up or buckle.

Also Read:

12 Reasons why Tiles Get Buckled or Popped-up or Tent?

Material Buying Guide for Ceramic Tiles

Make a Right Choice Between Ceramic Tiles and Vitrified Tiles