Los Angeles Abrasion Test can be executed to test the hardness property of aggregates and to decide whether they are suitable either for concrete, road construction or pavement construction. There are 3 tests commonly used to test aggregates for its abrasion resistance. (a) Deval Attrition Test (b) Dorry Abrasion Test (c) Los Angeles Abrasion Test.

Los Angeles abrasion test gives the best realistic results of hardness property and it has also been standardized in India (IS: 2386 part-IV). To find out the performance of aggregates for various uses, 7 types of lab test are available.

The Principle of Los Angeles Abrasion Test:

The principle of Los Angeles abrasion test is to find the percentage wear due to relative rubbing action between the aggregate and steel balls used as abrasive charge.

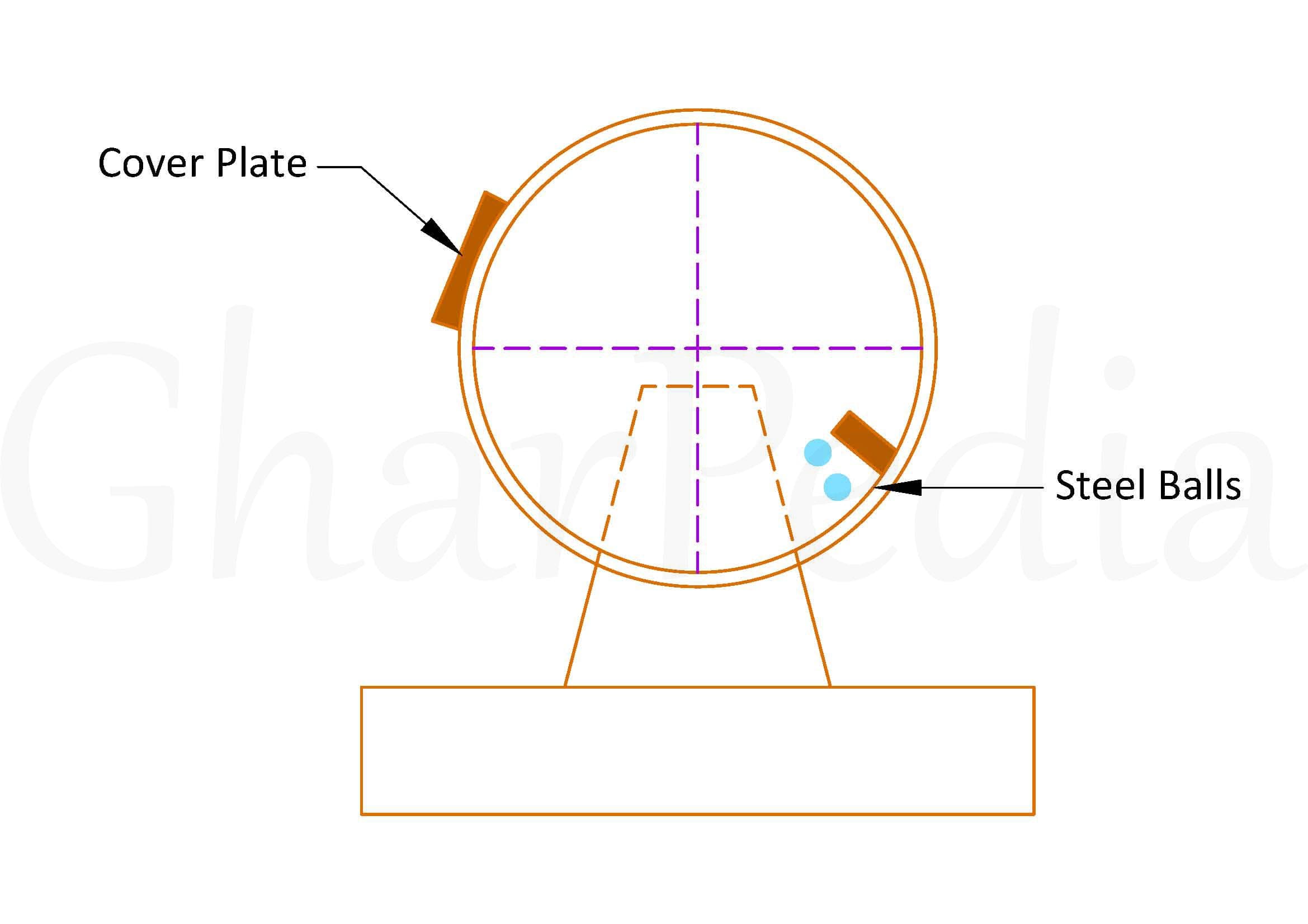

- Los Angeles machine made up of circular drum of internal diameter 700 mm and length 520 mm. it is mounted on horizontal axis that allows it to rotate.

- An abrasive charge made up of cast iron spherical balls of 48 mm diameters and weight ranges in between 340-445 g. it is generally placed in the cylinder along with the aggregates.

- The number of the abrasive charge spheres differs governing to the grading of the aggregate sample.

- The quantity of aggregates usually ranges from 5-10kg however; it depends upon the gradation of aggregates.

- The cylinder is then locked and rotated for a total of 500-1000 revolutions at the speed of 30-33 rpm depending upon the gradation of aggregates.

After above mentioned revolutions, the material is sieved through 1.7 mm. the difference between the original weight and the final weight (sieved through 1.7mm) is expressed as % of the original weight of the sample aggregate. This value is called as Los Angeles abrasion value.

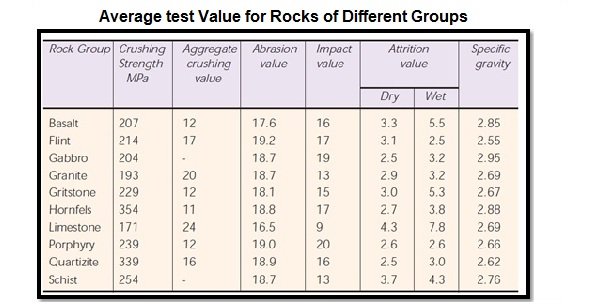

The maximum Los Angeles abrasion value should not be more than 30% for the use of wearing surface and not more than 50% for the use of concrete. Table 1 below presents the average Los Angeles abrasion test value for rocks of different groups.

Also Read: