Nowadays concrete testing experts are using the NDT test like penetration resistance test to determine the relative strength of the concrete in the structure. It estimates the strength of concrete from the depth of penetration of a steel rod. In this method, the steel rod or steel probe is fire on the concrete surface by a sudden explosion. The penetration is inversely proportional to the compressive strength of concrete in the standard test condition. This relationship depends on the strength of the aggregates.

Penetration resistance test rapidly and accurately determines the compressive strength of the concrete. The strength is found out by firing (shooting) a probe or pin on the surface of the concrete with the known amount of force.

Penetration resistance test is a modern system to measure the compressive strength of hardened concrete. It measures the concrete compressive strength up to 110 MPa.

Also, learn other NDT tests which are used to check the Hardened Concrete.

Rebound Hammer Test Procedure

Ultrasonic Testing Procedure

Concrete Pull Out Test

Carbonation Test

Chloride Content Test

How to get Idea About Steel Corrosion In Concrete?

Windsor Probe Test Procedure

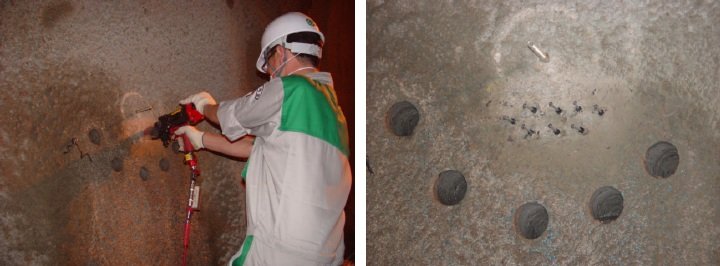

Courtesy - Qualitest - worldoftest

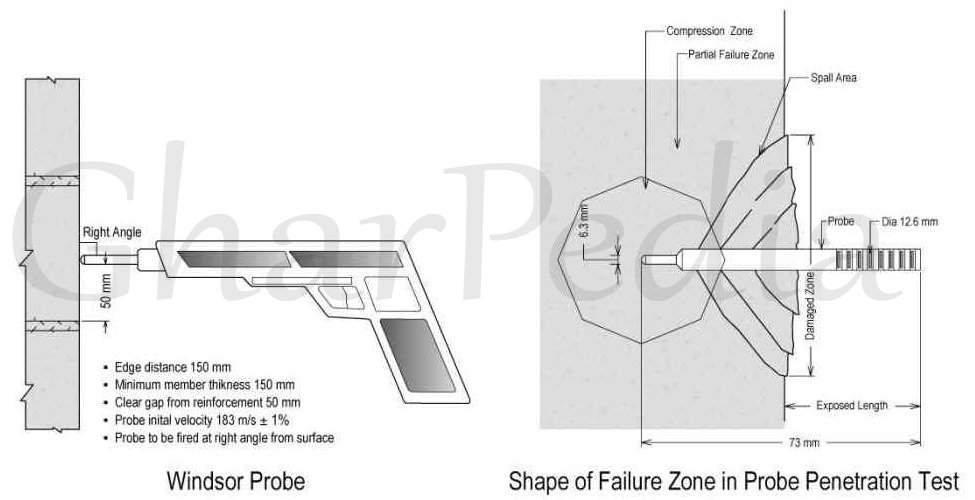

Windsor probe equipment is famous penetration resistance measurement equipment for the concrete. The technique consists of accessories like a gunpowder actuated driver and hardened alloy rod probe. It also consists of accessories like loaded cartridges, a depth gauge etc.

A gunpowder actuated driver is used to fire a hardened alloy probe on the concrete. The depth of penetration depends on the strength of the concrete. Probes are fired in close vicinity and in a set of three. Use the average value to estimate the strength of concrete.

During testing, measure the exposed length of the probe by a calibrated depth gauge. But, it is preferable to express the coefficient of variation based on the depth of penetration as concrete strength is related to penetration depth.

Steel probe has a diameter of 6.3 mm and the length of 73 mm and has conical point at the tip. The rear of the probe is threaded and screwed, which is 12.6 mm in diameter. It fits snugly (in a way that is tight or close-fitting or securely) along with a rubber washer into the hole of the gun (driver).

Windsor probe test results are usually not affected by surface texture and moisture content. However, damage in the form of cracks in the house may be caused to slender members.

Precaution while Windsor Probe Test

- Provide minimum 150 mm edge distance from the surface of the member.

- Minimum thickness requires for the member is 150 mm.

- Leave 50 mm clear gap from the reinforcements present in the member since the presence of the reinforcing bars within the zone of influence of the penetrating probe affects the penetration depth.

- Provide initial velocity of 183 m/s to probe and 1% difference is allowable in velocity.

- Probe to be fired at the right angle from the surface.

It is necessary to follow all the precaution for the accurate result while carrying out Windsor probe test.

Pin Penetration Test Device or PNR Tester

Courtesy - researchgate

Pin penetration test device or PNR tester requires less energy than the Windsor Probe system. Being a lower energy device, sensitivity is reduced at higher strengths. Hence it is not recommended for testing concrete having strength above 28 N/sqm.

In this method, a spring loaded device which has the energy of about 1.3 % that of the Windsor probe is used. It is used to drive pointed hardened steel pin of 3.56 mm diameter on the concrete surface. The penetration of steel pin creates conical facture and a small hole (indentation) on the surface of the concrete.

The pin is removed from the hole, and the hole is cleaned with an air jet. The depth of the hole is measured with a suitable depth gauge. Each time pin penetration test requires a new pin as the pin gets blunted after use.

The strength properties of mortar and aggregate affect the penetration depth of the probe in the concrete. These strength properties are different than they are in crushing strength of cube, wherein the strength of mortar continuously governs the strength. Thus, the type of aggregate has a strong effect on the relation of concrete strength versus depth of penetration.

Graph shows the effect of aggregate type on relationship between concrete strength and depth of probe penetration.

The pin penetration test for compressive strength is based on calibration curves. It is obtained from laboratory tests on specific concrete with a particular type of aggregates (Hard or Soft aggregate). Aggregate hardness is determined from the standard sample provided along with the instrument.

The shape of aggregates and nature of equipment influences the scatter of individual probe reading. Hence it should not be expected to yield absolute values of strength. The size and shape of aggregate in the concrete mix also influences the reading of individual probe reading.

Penetration resistance test is not operator independent although verticality of the bolt relative to the surface is obviously important. The safety device in the driver prevents if the alignment is poor. It is observed that approximately 20% accuracy may be possible in strength determination of concrete in penetration resistance test.

Also Read:

Why Modern Buildings are Prone to Cracks Compared to Old Buildings?

Materials for Repair of the Concrete Structure