Building Foundation

Building foundation is the lowest part of a building which provides a proper base and strength for the building. Broadly speaking, building foundation is the most crucial aspect of any structure. A proper foundation is essential for longevity and sustainability of a building. The purpose of a building foundation is to hold up and hold together the load in form of any structure above it.

Types of Foundation

According to the ‘Swami Saran’ (Author of Analysis and Design of Substructure Limit State Design), the types of foundation is categorized into two main categories:

- Shallow foundation

- Deep foundation

There are several factors affecting the type of foundation:

01. Load the building needs to uphold

02. Type of Strata

03. Type of structures in the neighborhood

04. Location of the superstructure i.e. whether it is flood prone area, earth quake prone area, tsunami prone areaetc. or prone to any such natural calamities.

05. Cost of structure as comparison to cost of superstructure.

Apart from the above mentioned factors, there are still other factors taken into consideration while considering the type of foundation i.e. the climatic conditions where the structure is to be raised, material used for construction work, dead load, imposed load etc.

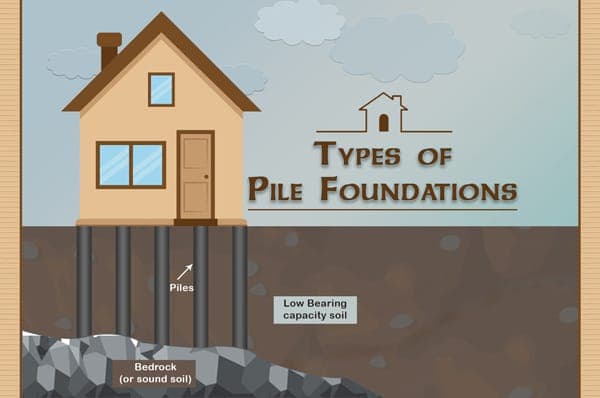

Pile Foundation

The pile foundation falls into the category of the deep foundations.

The Pile foundation is the common type of deep foundations used to transmit structural loads into the deeper layers of firm soil in such a way that the layers of soil or rock can sustain the loads. When there is a layer of weak, soft or loose soil at the surface of the earth. Such soil is incapable of upholding the weight of the building. Hence the loads of the building have to bypass this layer and shift to the layer of stronger soil or rock which is below the weak layer.

The Pile foundations are capable of taking higher loads. The Pile foundation is one of the oldest methods of providing a safe, sound and a dependable foundation.The pile foundation ensures that the building stands on the strong foundation and the pile is in the strongest part of the soil or ground. The best example of pile foundation is ‘Ghat’ at Kashi – Varanasi raised on the bank of Ganges.

A pile is an element of construction composed of timber, concrete, or steel or some combination of these materials. A pile is either driven into the soil or formed on site by excavating a hole and filling it with concrete.

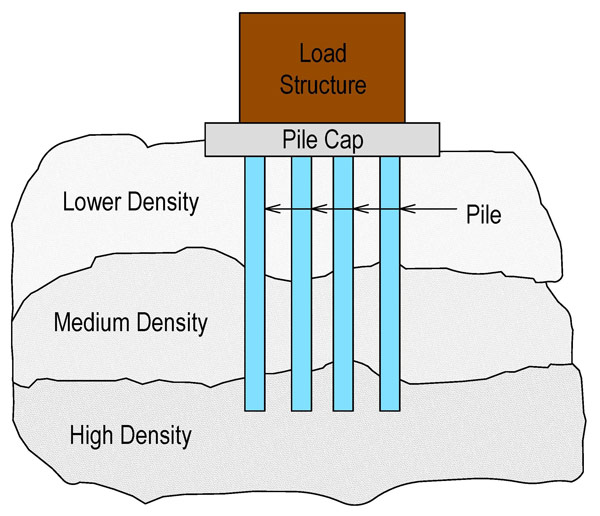

The Pile foundation consists of two major components:

- Pile cap

- Pile shoe

Pile transmits structural loads through zones of poor soil to a depth where the soil has the desired capacity to transmit the loads. A pile foundation usually consists of a number of piles, which together support a structure.

For the selection of type of piles, there are several factors one needs to take into consideration i.e.type of soil, its properties, loading conditions, position of groundwater table, facilities available for pile driving etc. If one has knowledge and understanding of these, selection of types of piles is not difficult.

Types of Piles

According to ‘DR.B.C.Punmia, Ashokkumar Jain, Arunkumar Jain’ (Authors of Soil Mechanics and Foundations),depending upon their function or use and based on the materials used in their manufacture, various types of piles are used:

(a) Pile Classification Based on Function:

Piles are of following types based on its use:

01. End bearing piles

02. Friction piles

03. Compaction piles

04. Tension piles

05. Anchor piles

06. Fender piles

07. Batter piles

08. Sheet piles

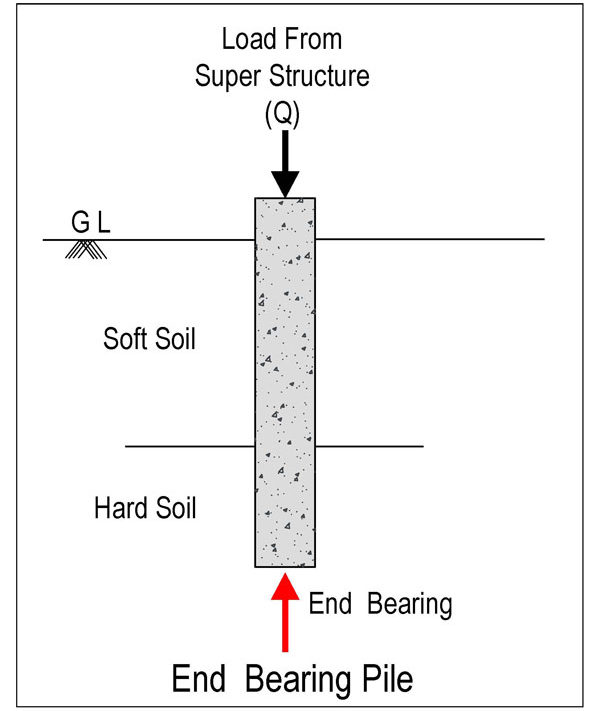

01. End Bearing Piles

- End bearing piles penetrate through the soft soil andtransfer its load to a hard and relatively incompressible stratum like rock or dense sand.

- These piles virtually act as columns.

- The soft soil surrounding the pile provides some lateral support.

- These piles derive its bearing capacity from end bearing at the pile tip.

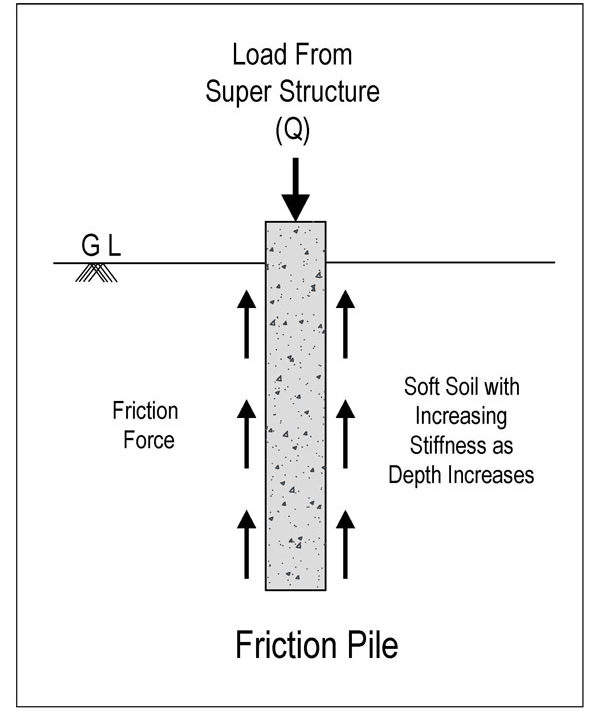

02. Friction Piles

The pile which does not rest on hard stratum but derives its load carrying capacity from the adhesion or friction/resistance between the pile surface and the neighbouring soil is known as friction pile.

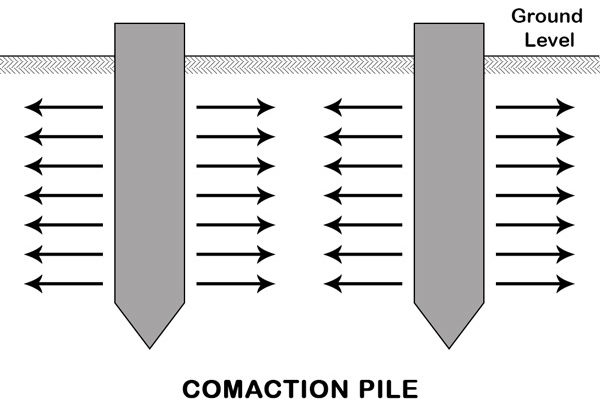

03. Compaction Piles

- The compaction piles are used to compact loose granular soil, thereby increasing their bearing capacity.

- Thesetypes of pilesdo not carry any load themselves.

- Sand piles can be used as compaction piles.

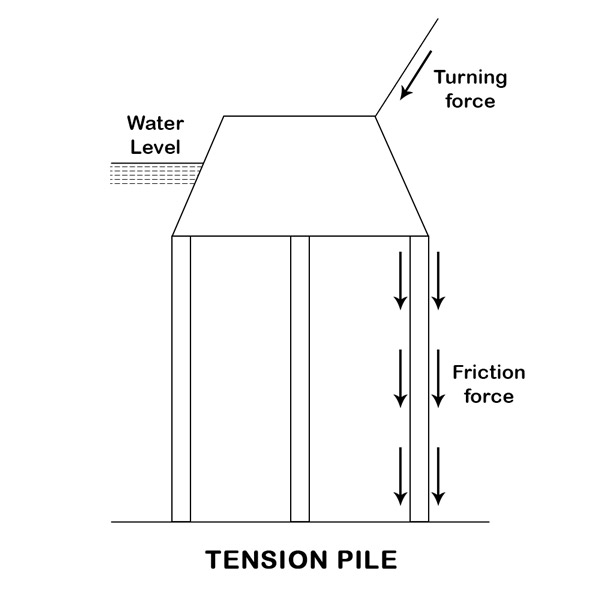

04. Tension Piles

- Tension piles are anchored down the structures subjected to uplift due to hydrostatic pressure or due to overturning.

- It is also called uplift pile.

05. Anchor Piles

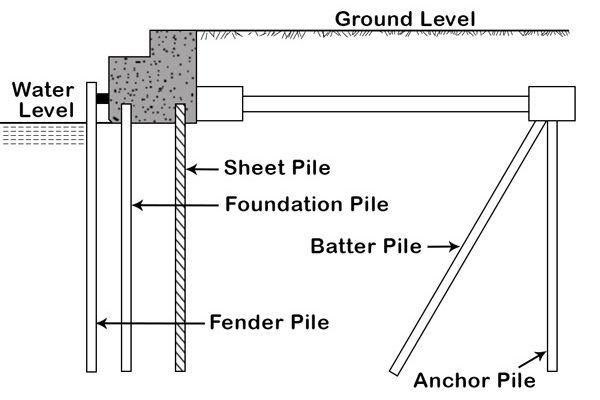

- Anchor piles provide anchorage against the horizontal force from sheet piling or other pulling forces.

06. Fender Piles

- Fender piles are used to protect waterfront structures against the impact from ships or other floating objects.

- It is reinforced to withstand handling stresses or excessive load for the structure constructed over water bodies.

07. Batter Piles

- Batter piles are used to resist large horizontal forces or inclined forces.

- Batter piles carry lateral loads primarily in axial compression and/or tension.

08. Sheet Piles

- Sheet piles are used as impervious cut off to reduce seepage and uplift in case of hydraulic structure.

- Sheet piles retain soil, using steel sheets with interlocking.

- Sheet piles are most commonly made of steel which resist them from bending. Steel sheets can also be formed of timber or reinforced concrete.

(b) Pile Classification based on Materials Used in their Manufacture:

Depending upon the function or usage, piles are classified as following:

01. Steel piles

02. Timber piles

03. Composite piles

04. Sand piles

05. Concrete piles

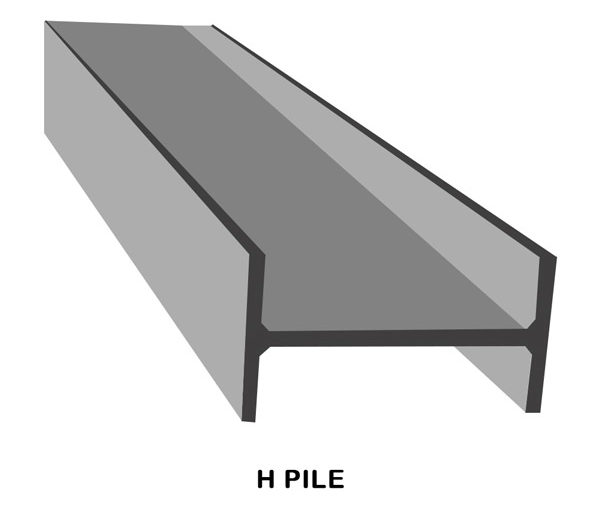

01. Steel Piles

According to ‘Sushil Kumar’ (Author of Building Construction), the types of steel piles commonly used are H – piles, Pipe piles, Screw piles, Disc piles etc.

(I) H – Piles

- H- Piles are usually of wide flange section.

- H-piles are dimensionally square structural beams.

- They are driven in the ground for deep foundation applications.

- They have a small cross-sectional area; therefore, they can be easily driven in soils in which it will be difficult to drive ordinary displacement piles.

- They are used as long piles with high bearing capacity.

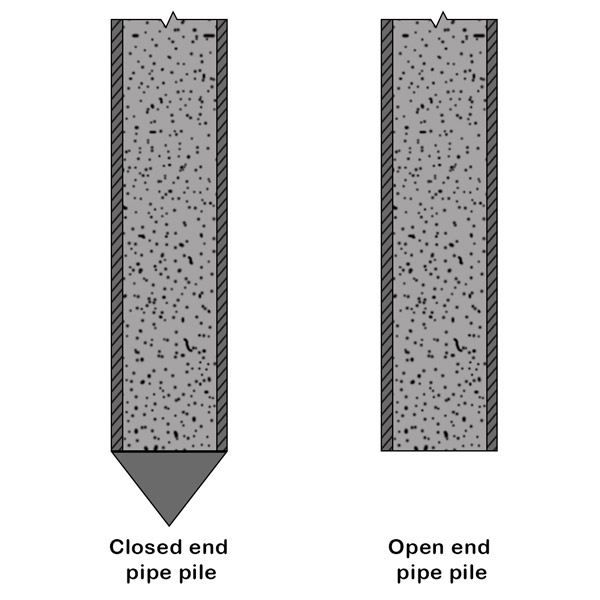

(II) Pipe Piles

- The pipe piles are driven either open-ended or close-ended.

- Pipe piles are designed to transfer structural loads through the foundation to strata below.

- As the open-ended piles are sunk in the ground, the soil inside the pipe is cleaned out simultaneously.

- In case of closed-end piles, the driving of each pipe is closed by welding conical steel or cast-iron shoe to the pipe end.

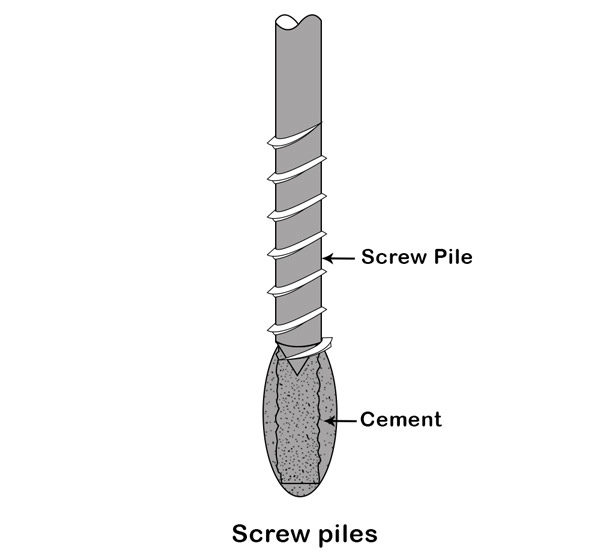

(III) Screw Piles

- Screw piles consist of cast iron or steel shaft of an external diameter generally varying 15 to 30 cm and terminating into a helix or screw base.

- The diameter of the screw at its bottom varies from 45 cm to 150 cm.

- These piles are used when the soil has poor load bearing capacity.

- Screw piles are a type of deep foundation that can be installed quickly with minimal noise and vibration.

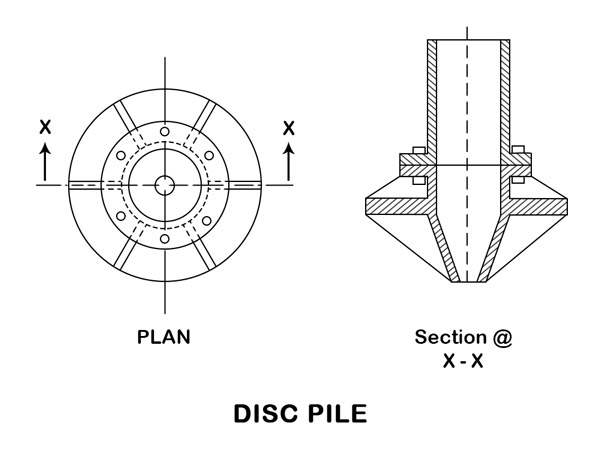

(IV) Disc Piles

- A disc pile consists of hollow metallic pipe attached with a cast iron disc to its foot to enlarge the bearing area of the pile.

- Disc pile can be used mostly in marine installations or in sandy or wet soils which may permit sinking of the pile by water jets, thereby providing penetration of the pile in an enlarged area.

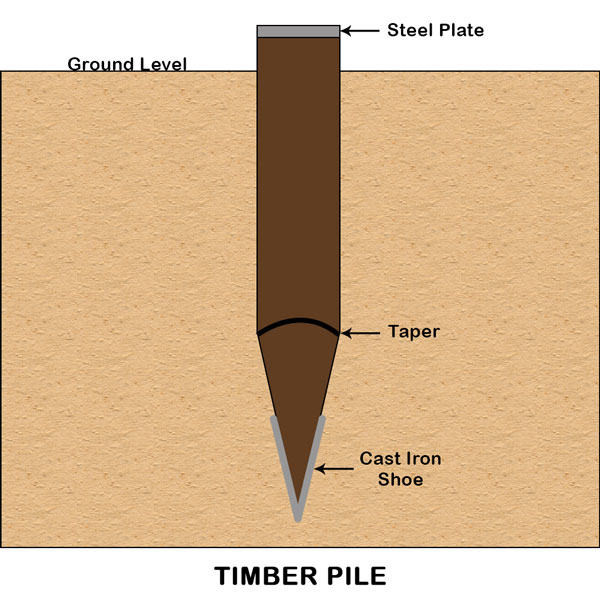

02. Timber Piles

- Timber piles are prepared from trunks of trees like sal, teak, deodar, babul, khair etc.

- At the bottom, a cast-iron shoe is provided and at the top, a steel plate is fixed in this pile.

- These piles have a small bearing capacity and are not permanent unless treated.

- Timber piles prove economical for structures to be located in compressive soils constantly saturated with water.

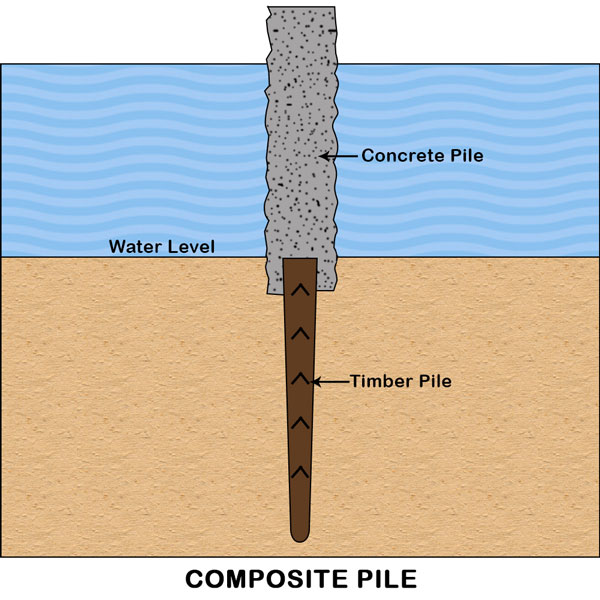

03. Composite Piles

- This is a type of construction in which piles of two different materials are driven one over the other, so as to enable them to act together to perform the function of a single pile.

- In composite pile the upper and lower portions consists of different types of materials. Thus, it takes advantage of good qualities of both the materials.

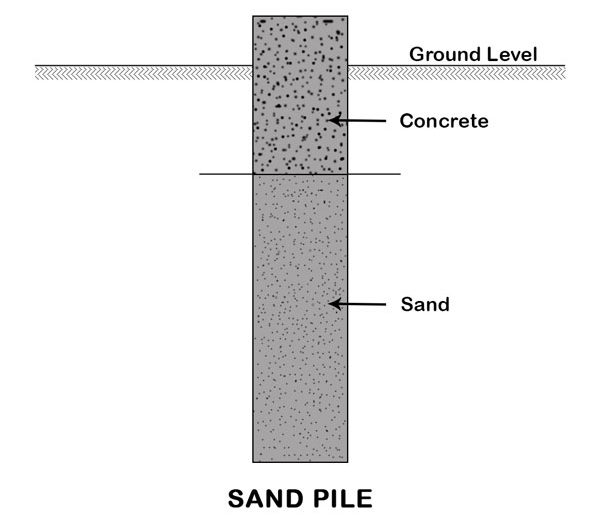

04. Sand Piles

- Sand piles are formed by making holes in the ground and then filling them with sand.

- If sand is confined, it possesses great crushing strength and becomes in compressible.

- They are basically used for compaction. Thus, they increase the bearing capacity of soil.

05. Concrete Piles

According to the ‘P.C. Varghese’(Author of Foundation Engineering Geotechnical Aspects),the various types of concrete piles are precast concrete piles, prestressed concrete piles, Cast-in-situ concrete piles etc.

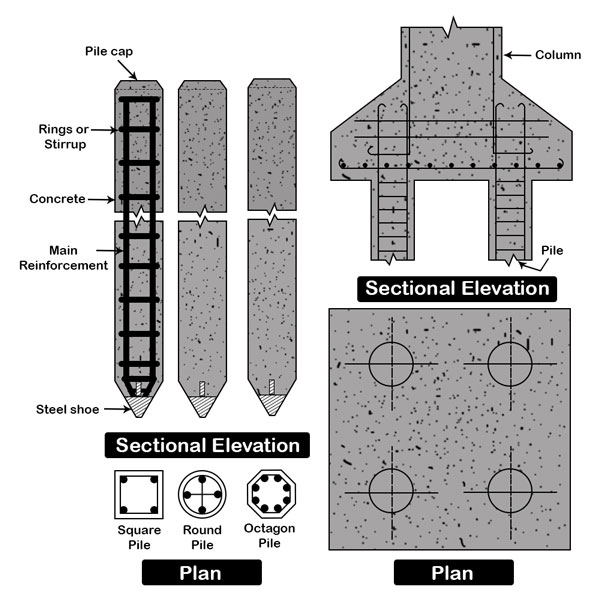

(I) Precast Concrete Piles

- The precast piles are reinforced concrete pile which is moulded in circular, square, or octagonal shape.

- Normally, these piles require heavy pile driving machinery.

- Precast concrete piles are preferred for permanent, durable and economical foundations- especially marine or bridge environment.

(II) Prestressed Concrete Piles

- Prestressed concrete piles are lessin weight and hence can be easily lifted from one or at the most two points.

- Due to their reduced weight, prestressed concrete piles have definite handling advantage over ordinary precast piles.

- They are getting increasingly popular these days.

(III) Cast-in-Situ Concrete Piles

In cast-in-situ concrete piles, a bore is dug into the ground by inserting a casing. After placing reinforcement, this bore is then filled with cement concrete. The casing may be kept in position or it may be withdrawn.

Cast-in-situ concrete piles are further classified into two categories:

- cased cast-in-situ concrete piles

- uncased cast-in-situ concrete piles

⇒ Cased-in-Situ Concrete Piles ⇐

A thin metal casing is driven first into the ground and subsequently the concrete is poured inside the casing. This is called cased cast-in-situ concrete piles.

The casing in such piles may be left in the ground permanently.

The types of cased cast-in-situ concrete piles are:

01. Raymond piles

02. Mac Arthur piles

03. Monotube piles

04. Driven piles

05. Swage piles

06. Button bottom piles

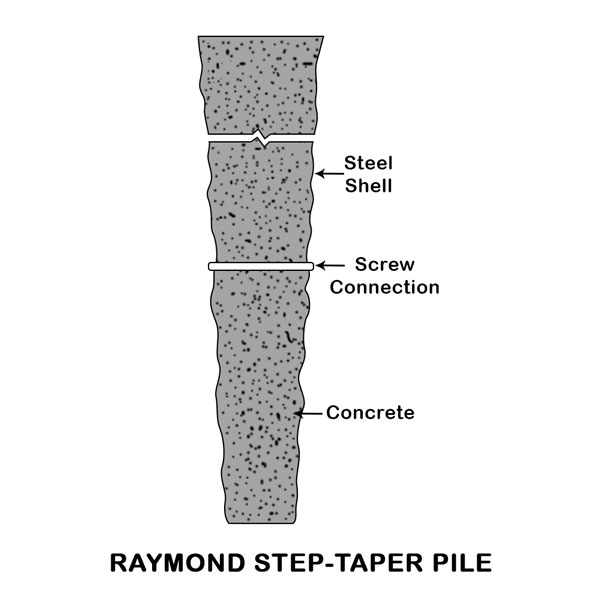

01. Raymond Piles

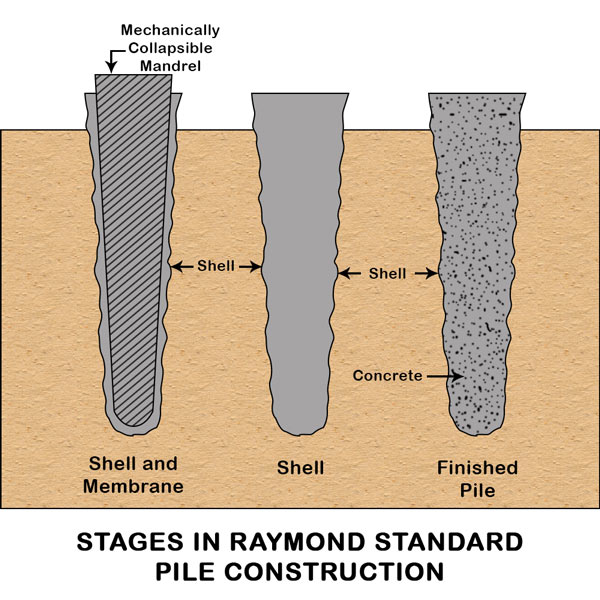

Raymond piles are further categorized as – Raymond standard concrete pile and Raymond step-taper concrete piles.

01 (a) Raymond Standard Concrete Piles:

- The shell is driven into the ground with a collapsible steel mandrel and core in it having the same taper.

- The length of piles varies from 6 to 12 m.

- The diameter of Raymond pile varies from 40 to 60 cm at the top and 20 to 30 cm at the bottom.

- The pile consists of a thin corrugated shell (casing) closed at the bottom.

- Raymond standard concrete pile is used primarily as a friction pipe.

01 (b) Raymond Step-Taper Concrete Piles:

- Raymond step-taper concrete piles are used as an end bearing or friction pile and can be driven in any soil.

- These piles contain shell section which can be driven in different length into the ground using a mandrel.

- The bottom sections of the shell are made of a heavier gauge and are closed by flat steel plate welded to the boot ring.

- The joints between parts of the shell are connected with the help of a screw.

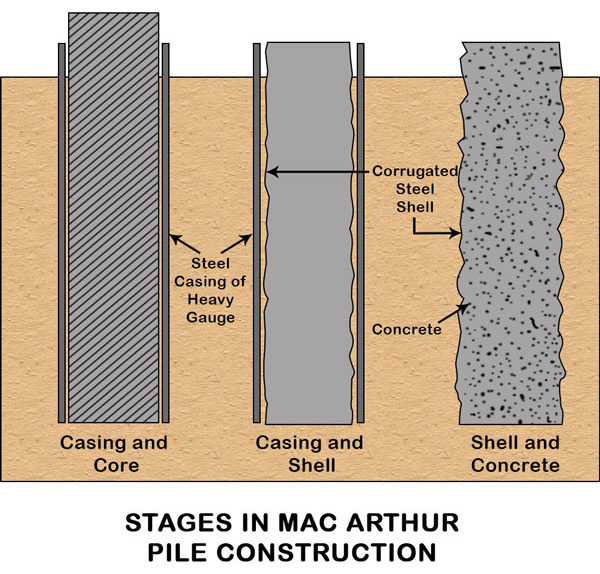

02. Mac Arthur Piles

- Mac Arthur piles have a uniform diameter, using the corrugated steel shell which remains in place.

- A heavy steel casing with a core is driven into the ground.

- When it reaches the desired depth, the core is withdrawn, and a corrugated steel shell is placed in the casing.

- Finally, concrete is filled in the corrugated steel shell and outer hard casing is removed after gradually compacting it.

03. Monotube Piles

- Monotube piles are suitable for a wide variety of soil conditions.

- The shells provide rigidity as they are made of corrugated and reinforced thin sheet steel. They are watertight.

- The pile shells are driven to the required depth, and they are inspected after driving.

- The shell after the inspection is filled with concrete, and excess length of the shell is cut out.

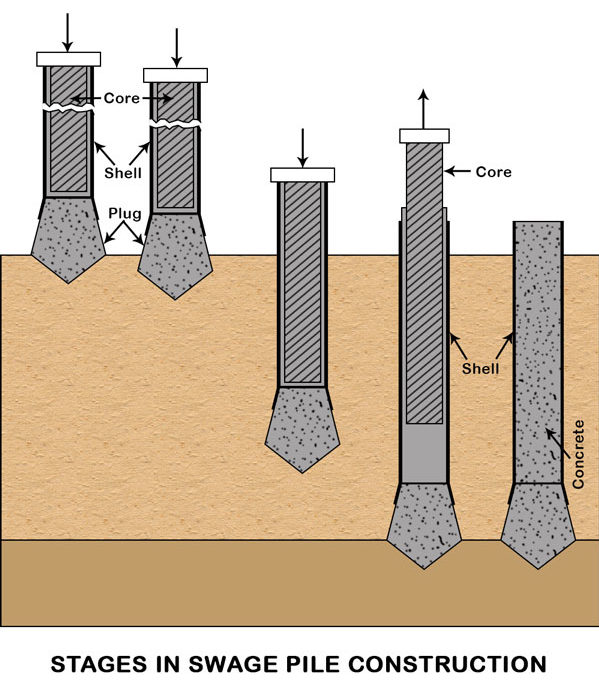

04. Swage Piles

- The swage piles are used with advantage in some soils where the driving is very hard.

- These piles are designed to leave watertight shell for some time before filling the concrete.

- A shell (Thin steel pipe) is placed on the concrete plug and steel core.

- Shell is driven over the plug until the core reaches the plug; the pipe is swaged out by taper of the plug, thus forming a watertight joint.

- Once the shell has reached the desired depth, the core is removed, and the shell is filled with concrete.

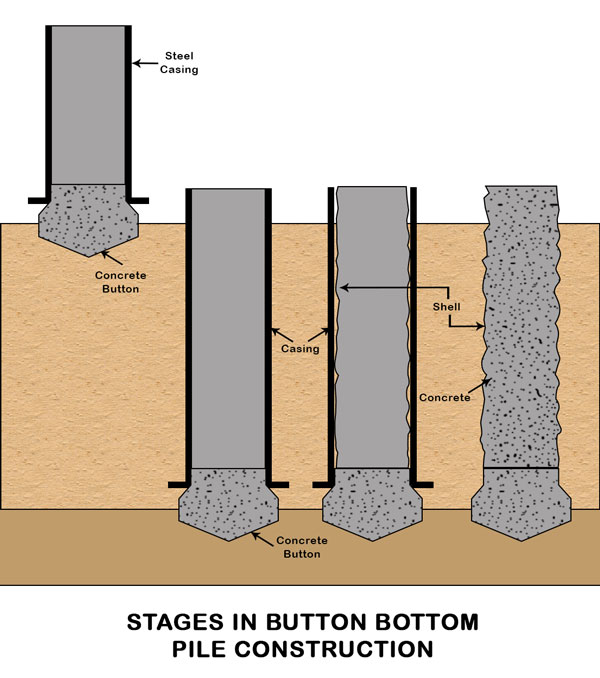

05. Button Bottom Piles

- The button bottom piles are used in locations where an increase in the bearing area at the end is desired.

- The pile uses a concrete plug that is button shaped. This is how the pile derives its name.

- During driving, this button forms an enlarged hole in the soil.

- These piles have been used up to lengths of about 23 m and load up to 50 tonnes capacity.

- A steel pipe and reinforced base of cast steel are set over the concrete button.

- The pipe and button are driven to a specified depth; corrugated steel shell is then inserted in the pipe, and rested on the button.

- The casing is withdrawn, and the button is left in place. The shell is then filled with concrete.

⇒ Uncased Cast-in-Situ Concrete Piles ⇐

In uncased cast-in-situ concrete piles, a thin or relatively thick metal casing is driven first into the ground. The casing is then taken out gradually and concrete thus makes a bond with the neighbouring soil. They are cheaper in comparison to the cased piles. But the cost certainly compromises with the efficiency. Skilled workers are required for its installation.The types of uncased cast-in-situ concrete piles are:

01. Simplex piles

02. Franki piles

03. Vibro piles

04. Pedestal piles

05. Bored piles

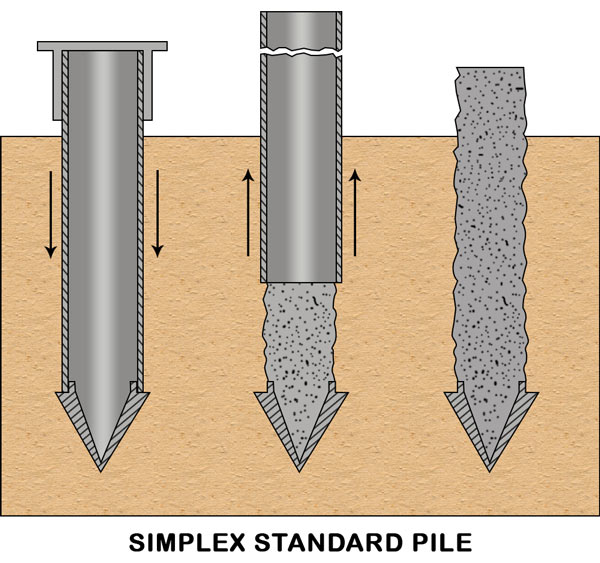

01. Simplex Piles

- Simplex piles can be driven into soft or hard soils.

- In this type of pile, a steel tube fitted with a cast iron shoe is driven into the ground up to the desired depth.

- After that, reinforcement is provided in the tube and then filled it with concrete. Tube is gradually withdrawn, leaving behind the cast iron shoe at the bottom.

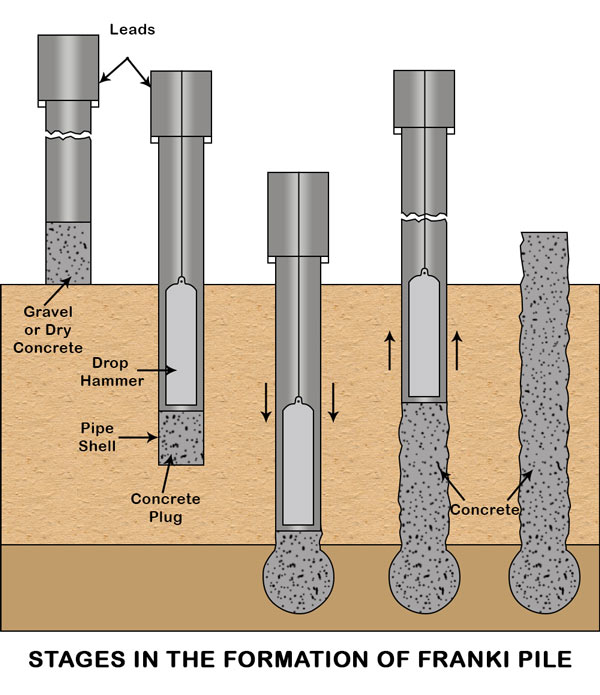

02. Franki Piles

- Franki piles have an enlarged base of the mushroom shape, which gives the effect of a spread footing.

- This pile is useful where a bearing stratum of limited thickness can be reached at a reasonable depth.

- Franki pile is best suited to granular soil.

- A heavy removable shell consisting gravel or concrete are set on the ground with the help of leads.

- Some portion of concrete is placed in the tube and ramming is done with hammer.

- The tube held in position by lead and hammer is applied to the concrete, forcing it down and outward.

- As a result, the enlargement of the base into the mushroom shape taken place.

- The shaft is formed by successive charges of concrete, ramming each in turn, and gradually withdrawing the casing.

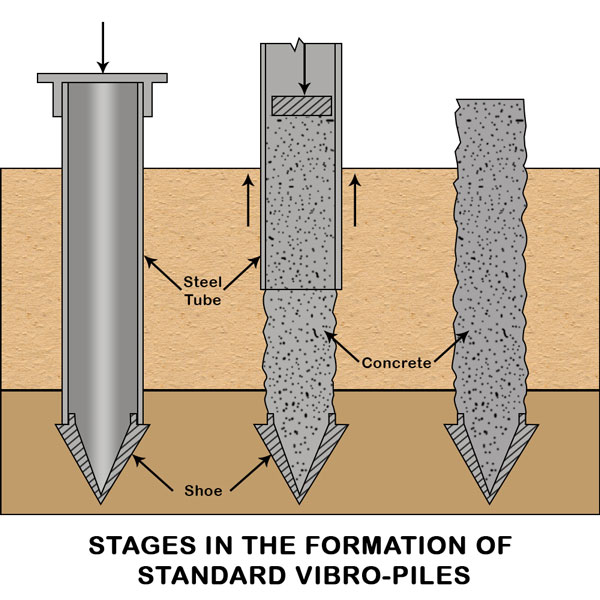

03. Vibro Piles

- Vibro piles are used where the ground is soft. Vibro piles offer little frictional resistance to the flow of concrete. These piles are formed by driving a steel tube and shoe, filling with concrete, using upward extracting and downward tamping blows alternatively.

- There are two types of vibro piles formed by the vibro process (1) standard vibro-pile (2) vibro-expanded pile.

03 (a) Standard Vibro-Pile:

- In these piles, a steel tube, fitted with a cast iron shoe is driven in the ground by the hammer.

- When the shoe and the tube reaches the desired level, the hammer is fitted at the top of the tube.

- The tube is withdrawn when concrete is consolidated in each downward blow.

- Thus, the concrete is being forced down to occupy the space left by the tube, resulting in corrugated face of the pile.

- The corrugated face gives rise to increased frictional resistance and consequently, increases the bearing capacity.

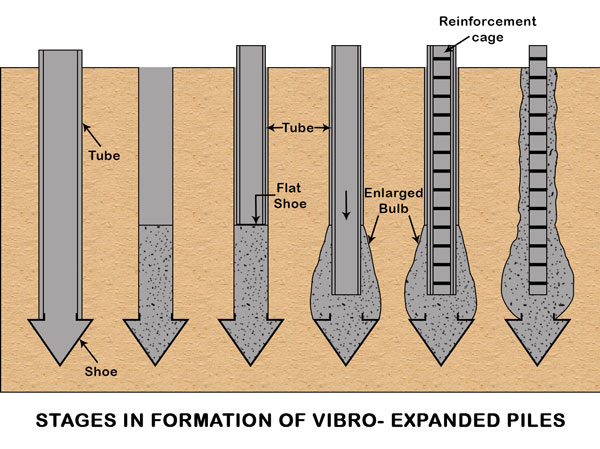

03 (b) Vibro-Expanded Pile:

- These piles are used where the desired driving resistance is not obtained at reasonable depth due to low bearing capacity of the soil.

- In these piles, the tube, fitted with the conical shoe is driven in the ground up to the desired depth.

- Concrete is filled in the tube, up to some reasonable depth.

- The tube is withdrawn, leaving behind the conical shoe and the concrete over it.

- The tube fitted with a flat shoe is again lowered in the hole until it reaches the deposited concrete.

- The tube is driven down along with flat shoe to penetrate the concrete, resulting in the bulged end.

- The reinforcement cage is lowered in the tube so that it rests on the flat shoe.

- The tube is now filled with concrete, and the pile is completed by a succession of upward extracting and downward consolidating blows, as in the standard vibro pile.

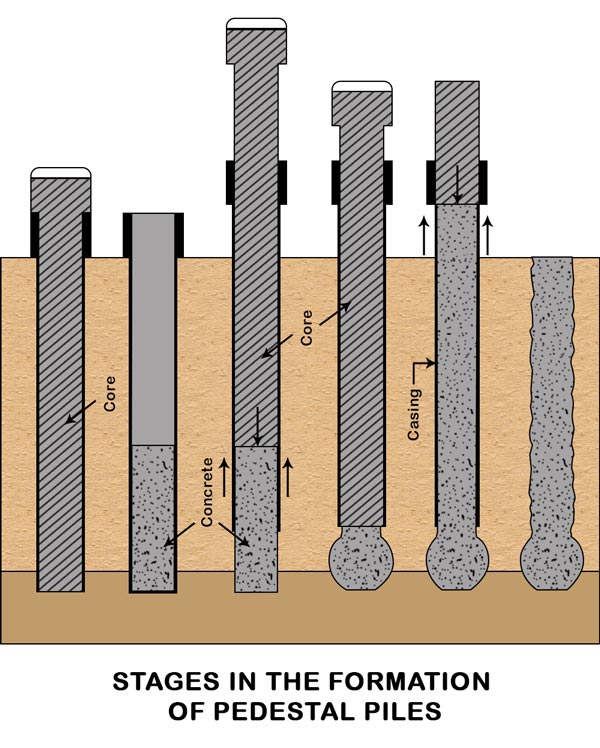

04. Pedestal Piles

- Pedestal piles are used where thin bearing stratum is reached with reasonable depth.

- In these piles, the pedestal gives the effect of spread footing.

- The core and casing are driven together into the ground, till they reach up to the desired level.

- The core is taken out and concrete is placed in the tube.

- The core is replaced in casing till it rests on top of the poured concrete.

- The concrete is rammed out, thus resulting in the formation of the pedestal.

- The core is removed; the casing is filled with concrete.

- The casing is pulled up while maintaining the pressure of core and hammer on the concrete.

- Pedestals are provided so as to avoid the direct contact of metal columns with soils which can result into possibility of corrosion of metal by soils.

05. Bored Piles

The Bored piles are formed by forming a borehole in the ground and then concreting it, either with the help of the casing tube or without a casing tube.

Bored piles are also known as replacement piles as the soil is replaced by the pile. These piles provide foundation that supports structure with heavy vertical loads.

The bored piles construction entails two main steps- the drilling phase and the construction phase.Bored piles are mainly of three types:

- Pressure piles

- Under-Reamed piles

- Bored compaction piles

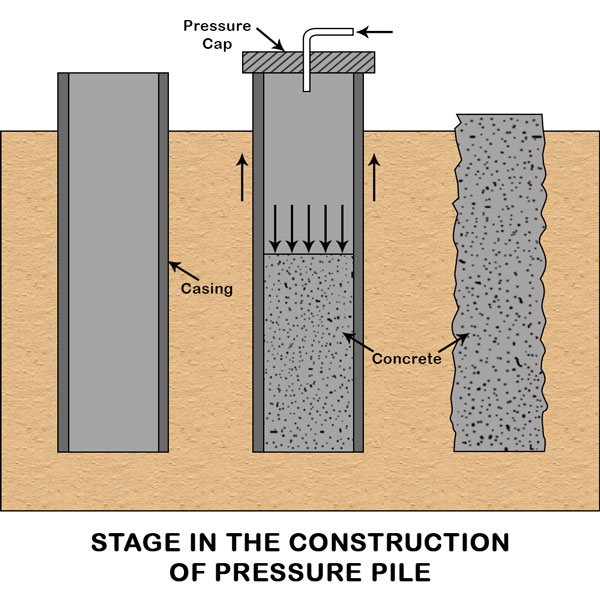

05 (a) Pressure Piles:

- Pressure piles are formed with the help of a casing tube, boring auger and compressed air equipment.

- These piles are especially suitable for those congested sites where heavy vibration and noise are not permissible.

- A boring tool, such as an auger working inside it, excavates the soil. The bored soil is continuously taken out, and the hole is cleaned.

- Concrete is placed in the tube, and the upper end of the tube is closed with the help of a pressure cap. Compressed air is introduced through the air pipe of the pressure cap. Thus, forcing the concrete down and out against the surrounding soil.

- The process of compressed air application is repeated, till the complete pile is cast, and the tube is completely taken out.

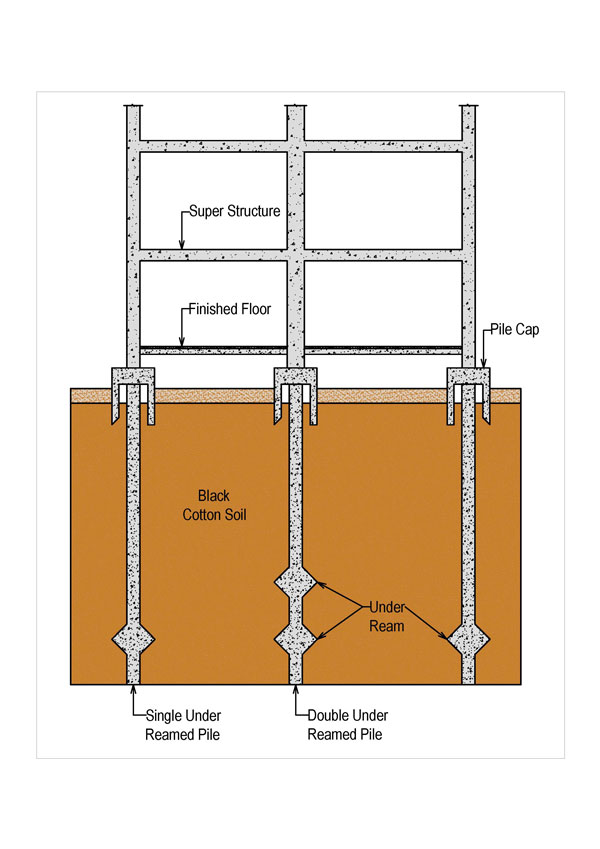

05 (b) Under-Reamed Piles:

- An under-reamed pile is a bored cast-in-situ concrete pile having one or more bulbs or under reams at its lower portion.

- The bulbs or under reams are formed by under reaming tool.

- When only one bulb is provided at the base, it is known as a single under-reamed pile.

- When two or more bulbs are provided at the bottom, it is known as multi-bulb under-reamed pile.

- These piles are best suited in soils where substantial and significant movements prevail due to seasonal discrepancy.

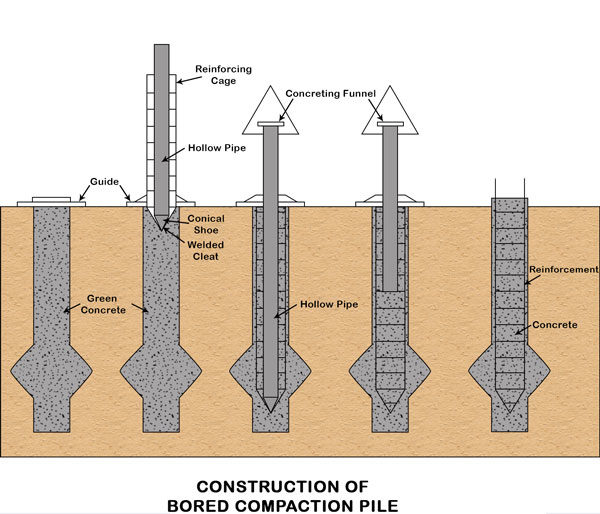

05 (c) Bored Compaction Piles:

- Bored compaction piles are the modification of under-reamed pile.

- These piles are cast-in-situ piles which integrates the advantages of both bored piles and driven piles.

- The method of boring and concreting the bored compaction pile is same as that for under-reamed pile, except that the reinforcement cage is not placed in the borehole before concreting.

Thus, depending upon the stratic conditions and other ground conditions, the different types of pile are used. According to ‘Sushil Kumar’ (Author of Building Construction), nature of the ground, groundwater table, loading conditions, probable length of piles required, availability of materials and equipments, availability of funds, probable cost of the pile, erosion of soil near the structure, etc. are some factors which will help in the selection of types of piles.

Must Read:

Foundation System: All the Basic Things You Need to Know

7 Important Requirements that the Foundation System should Meet