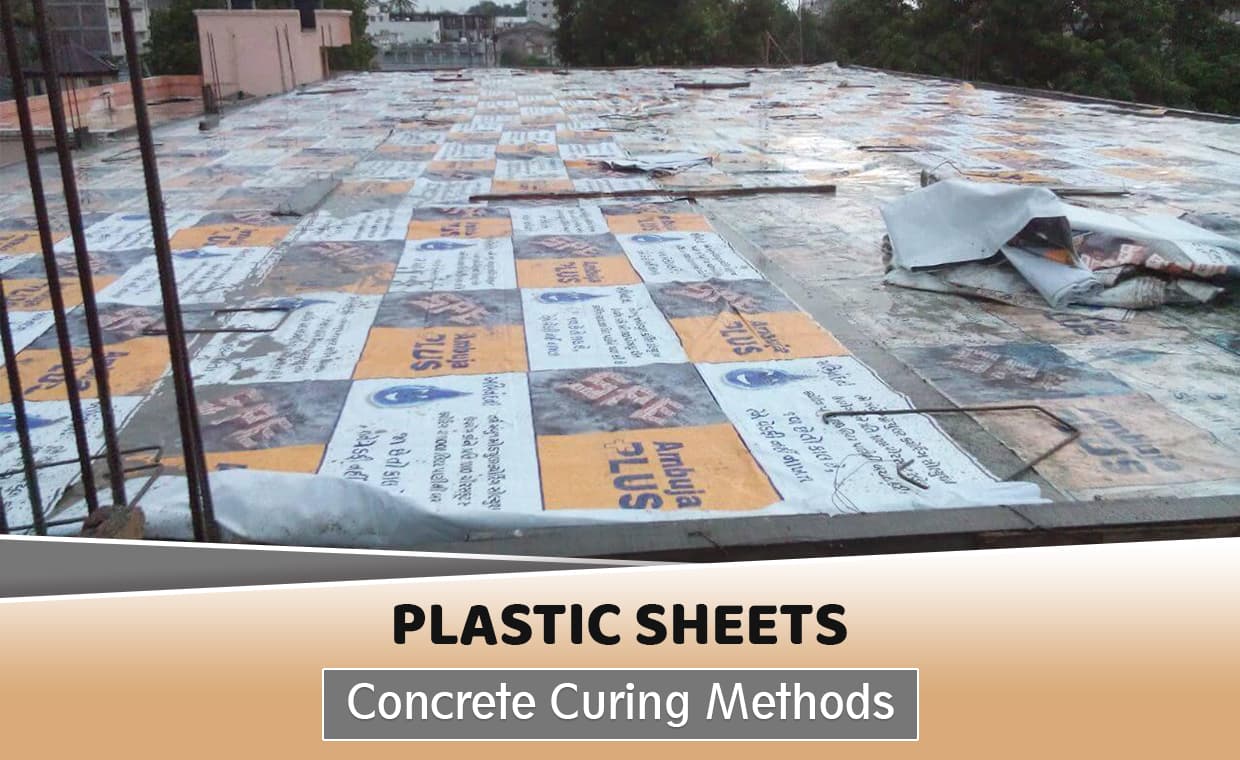

Curing of concrete is the process of maintaining moisture inside the concrete for continuing hydration process of concrete. Insufficient hydration process affects the strength of the concrete. When some concrete works are carried out in places where there is an acute scarcity of water. Even optimum use of water for concrete curing is not possible for economic reasons. Concrete curing does not mean the only application of water but it also means also the creation of condition for continuous and progressive hydration. The quantity of water normally mixed for making concrete is more than sufficient to hydrate the cement and this water shall not be allowed to go out from the body of concrete. For this reason, concrete could be effectively covered with a plastic sheet so that it seals the evaporation of water from concrete. The curing concrete with plastic sheeting, after a short spell of water curing for one or two days is sometimes beneficial.Sometimes, concrete work is carried out in some inaccessible, difficult or far off places. The curing of such concrete cannot be properly supervised and sometimes it is entirely left to the unskilled workmen, who do not quite understand the importance of regular uninterrupted curing. In such cases, it is much safer to adopt plastic sheet curing rather than to leave the responsibility of curing to unskilled workers.A plastic sheet made from polyethylene film is an effective moisture retarder, lightweight and can be used on horizontal and vertical surfaces as well as on the surface of different shapes and sizes.

During hot weather white colour sheeting is used to minimize heat gain by absorption of solar radiation. In cold weather, lack colour sheeting is used to maximize heat gain.

However, there are some Precautions, Need to be Exercised when this Method is Used:

- Plastic sheets should be firmly placed on the concrete surface and all edges and corners must be kept well covered. This is done so that wind does not blow away the sheets at the edges and corners and dry out the concrete in these areas.

- Lap joint should be minimum 300 mm between the sheets.

- The sheets should be in close contact with the concrete surface as it causes rapid drying of the moisture from the concrete top surface.

- The vertical surface must be firmly fixed with tapes or strings

- Plastic sheets should be placed and fixed within half an hour of removal of formwork from vertical surfaces. On slabs, the sheets should be placed when the concrete has hardened enough to prevent surface damage.

- Never spread wrinkling plastic sheets on the horizontal surfaces, it may cause discolouration in patches.

- The polyethylene film should be of at least 0.10 mm i.e. 100 microns thick and preferably be transparent or white opaque in colour.

- After placing the sheet firmly on the concrete surface, water should be allowed to flow between the concrete and the sheet.

- After layer of soaked hessian cloth or burlaps are placed on the concrete surface they are covered with plastic sheets which help in retaining moisture for a very long time as evaporation is virtually prevented as condensation of water vapour take place on the internal site where drying shrinkage cracks and crazing are repeatedly observed.

Nowadays, water is scarce. Plastic sheets for concrete curing is the efficient method than other concrete curing methods as it saves the plenty amount of precious water.

Also Read:

How to Cure Concrete by Ponding Method?

Why Curing of Concrete is Very Important in a Construction?

What is bleeding in Concrete?

Tips to avoid or reduce Segregation in Concrete