With increasing population density and urbanization, land with poor geotechnical characters are inevitably used for constructing buildings. Soils near sea, river and at such other places possess poor strength and are not fit for resting foundations. In such cases, deep foundation come for rescue, as you cannot lag foundations on upper strata.

Deep foundations are provided in situations where,

- It is necessary to provide resistance to uplift.

- There is a chance of erosion due to flowing water or other reasons.

Piles are slender structural members installed in the ground to support a load or compact the soil. The primary purpose of providing pile foundation is transferring load from the superstructure through weak compressible strata or water onto stiffer and more compact soils or rock. Piles are made up of several materials or combinations of materials and are installed by various techniques like impact driving, jacketing, vibrating, jetting, drilling, grouting or combinations of them.

It is challenging to summarize and classify the piles because there are many types of piles, and they get upgraded frequently. However, based on the materials used in manufacturing of the piles, they can be classified into concrete piles, timber piles, steel piles, composite piles and sand piles.

Concrete piles are further divided into,

- Precast Concrete Pile

- Cast-in-situ Concrete Pile

- Prestressed Concrete Pile

The following discussion deals with precast concrete piles

What is Precast Concrete Pile?

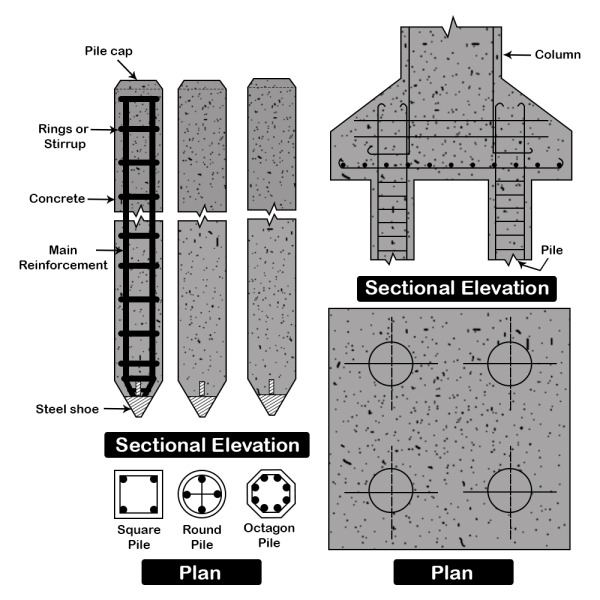

Precast Concrete Piles are the most common type of deep foundation used, to transmit loads through the upper zones of the poor soil to a depth where the soil is capable of providing adequate support. The precast concrete pile is a reinforced concrete pile which can be circular, rectangular, square, or octagonal in shape. The steel reinforcement in a precast concrete pile is provided to resist the stresses produced due to its handling, driving and loading which the pile is finally expected to receive.

These piles are constructed by conventionally reinforcing the concrete with internal reinforcement cage made up of several longitudinal and lateral steel bars and in the form of individual ties or a spiral.

The precast piles are constructed in a casting yard to a specified length, cured and then transported to the construction site. If space is available and a large quantity of piles are needed, a casting yard is provided at the site to reduce transportation cost. Precast piles are driven similarly as timber piles using pile drivers.

Types of Precast Concrete Piles

There are two types of precast concrete piles such as,

01. Driven Precast Concrete Piles

- Driven precast concrete pile is constructed of reinforced concrete in a casting yard and once it attains sufficient strength it is hammered into the ground to a depth of more than 40m using a hammer.

02. Bored Precast Concrete Piles

- Bored precast concrete pile is a type of precast pile which is constructed in reinforced concrete in a casting yard and subsequently lowered into pre bored holes. Later, the space between the pre bored holes and piles is grouted.

Bored precast concrete piles have advantage over the driven precast concrete piles, in following locations and situations,

- Where the vibrations and noise caused by the driving of piles are to be avoided.

- The strata of adequate bearing capacity are so deep that they are difficult to reach by driven piles.

Advantages of Precast Concrete Piles

- Precast concrete piles compact the soil. Therefore, the main advantage of using these piles is increasing the bearing capacity of the soil.

- These piles can be made in various sizes, shapes and lengths and used at the site. As a result, the progress of project work will be faster.

- The position of the reinforcement in these piles is not disturbed from its original position.

- The construction of these piles can be well supervised, and any defect detected can be rectified before use.

- The Precast Concrete Piles can also be driven underwater.

- Precast piles can be immediately loaded after they have been driven.

- The driving of an adjacent pile does not produce an adverse effect on the already driven piles.

- These piles are highly resistant to the biological and chemical action of the subsoil.

- No waste generation on the site.

- It is not affected by the groundwater.

- It is the most economical form of deep foundation

- Precast concrete piles can withstand high pressure vertical loads as well as high tension loads.

Disadvantage of Precast Piles

- Precast Concrete piles are heavy. Therefore, they require special types of equipment for handling, transportation and driving.

- If sufficient care is not taken, these piles may break during transport or driving.

- Precast piles require heavy pile driving machinery for installation.

- It requires extra reinforcement to bear handling and driving stresses which otherwise are not needed. Hence these piles are costly.

- The length of the pile has to be limited since it depends upon the transport facilities.

- It is difficult to increase the length of the pile based on previously estimated borehole data.

- If the pile is found to be too long, during driving, it is difficult and uneconomical to cut the pile.

- These piles are not available at short notice. Hence delay of work will occur for projects having emergency and when changes are needed.

Necessary Information About Precast Concrete Piles

According to ‘Swami Saran’ (Author of Analysis and Design of Substructures Limit State Design), these things are to be kept in mind while opting for precast concrete piles.

- Precast Concrete piles are used in lengths up to about 20 m. The length of the pile depends on the soil condition and position of the water table. To increase the length of pre-cast piles, two piles are connected with the help of fish plates and bolts.

- The piles are driven by hammering them at the top. Hence maximum stresses are developed at the top due to direct strokes, and at the point in overcoming the resistance to penetration, therefore additional reinforcement should be provided.

- The minimum grade of concrete used in construction of precast concrete pile is M25.

As per Indian Standard Code, for satisfactory design and construction of precast concrete piles, the following information would be necessary,

- Site investigation data has to be carried out as per Indian standard code (IS – 1892).

- Based on appropriate tests of strength, compressibility etc., the nature of the soil around and beneath the proposed pile should be assessed.

- Groundwater level and artesian conditions also need to be mentioned.

- Chemical properties of soil should be evaluated and studied so that there is no loss after constructing them.

- All loads including seismic, wind and forces due to water current, etc. should be indicated separately.

- In the case of bridge foundation, data on high flood level, maximum scouring depth, normal water level during the working season, etc. along with other hydrological data should be provided.

- Sufficient Information of nearby existing structure and experience of piles in the area close to the proposed site should be carried out, to determine the level of the foundation.

- Design of driven precast concrete piles should conform to Indian Standard Code -2911 – Part -I/ Sec-III and Design of bored precast concrete piles conform including sequence of works to Indian Standard Code -2911 – Part -I/ Sec-IV.

- Prepare complete working drawings for the execution of work.

Procedure for Casting Precast Concrete Piles

- Prepare formwork for the pile.

- The cage of reinforcement is prepared as per the design, and this cage is then placed in formwork.

- Prepare the grade of concrete which is specified in the design.

- The concrete is laid in formwork and well compacted using vibrators.

- The piles are then shifted to a curing tank, and after the curing, they become ready for use.

Precast Concrete Pile Installation

The operation of forcing a pile into the ground is known as pile driving or installation of pile. Pile driver is an equipment used to lift the hammer and allow it to fall on to the head of a pile.

The piles are driven into the ground by means of hammers or vibratory drivers. In certain situation, piles can also be inserted by jetting or partial augering. The type of hammer used for pile driving are

- Drop Hammer

- Single-acting hammer

- Double-acting hammer

- Diesel Hammer

- Vibratory Hammer

In the pile driving operation, a pile cap is placed on the top of the pile. The primary function of a pile cap is to support the superstructure of a building. The cap has to be designed with care so that there is no failure of structure.

To know more about the installation of the precast concrete pile, watch this online documentary by McDonnell. (It is a Company that provide a range of geotechnical solution for any ground condition in Ireland and investigate, review and recommended then give practical and realistic advice.)

There are various types of pile driving machines built for different types of soil and the pile material. However, all of them basically consist of a heavy weight placed between guides so that it can move up and down in straight line. The driving force comes from the repeated hammering action as the weight is dropped on the pile head, raised and dropped again using hydraulic or compressed air for the operation.

Final Thought

Pile foundation is the oldest method of providing a safe, sound and a dependable foundation. A pile is an element of construction consisting of timber, concrete, or steel or combination of these. It is either driven into the soil or formed on-site by excavating a hole and grouting bore with concrete.

A pile foundation usually consists of several piles, which together support a structure. Selection of type of pile depends upon the nature of the structure, loading conditions, type of soil and its properties, groundwater table, facilities available for pile driving, maintenance cost etc.

According to ‘Michael Tomlinson & John Woodward’ (Author of Pile Design and Construction Practice), Precast Concrete Piles have their principle use in a marine structure, i.e. in situations where the use of cast-in-situ concrete piles or prestressed concrete piles is impracticable or uneconomical. Also, Precast concrete piles are suitable for the places where timber piles are likely to be weakened by the termites or other insects.