The soil at a construction site may not always be suitable for supporting structures like buildings, bridges, highways and dams. The soil at the construction site may be very loose and indicate a large elastic settlement. In such a case, the soil needs to be densified to increase its unit weight and shear strength.

Sometimes the top layers of soil are undesirable and must be removed or replaced with a better soil on which the structural foundation can be built. The soil used as a filling material should be well compacted to sustain the desired structural load.

Depending on the structural load and the depth of layers, unusually large settlement may occur. Special soil improvement techniques are required to minimize the settlement of the structure. The various methods are used to

- Reduce the settlement of the building.

- Improve the shear strength of the soil and thus increase the bearing capacity of a shallow foundation.

- Increase the factor of safety against possible slope failure of earth dams and embankments.

- Reduce the shrinkage and swelling of soils.

There are many situations where the strength and other properties of soil have to be improved by ground improvement methods. Soil compaction is one of the best ground improvement methods. Let us understand what is compaction.

What is Compaction of Soil?

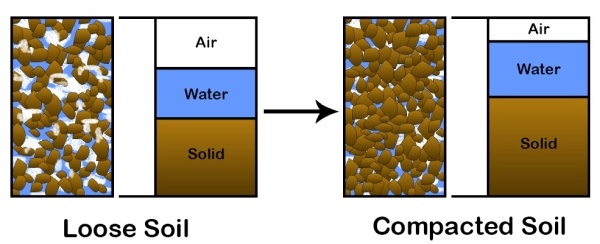

Compaction means pressing the soil particle close to each other by mechanical methods. Air during compaction is removed from the void space in the soil mass, and therefore the mass density is increased.

The soil compaction is a method of mechanically increasing the density of soil. It is a simple ground improvement method, where the soil is compact through external compaction effort.

Soil compaction is the process of applying external energy to a loose soil to consolidate it and remove air voids from the soil and thereby improving the physical properties of the soil. If performed improperly, settlement of the soil can occur and may result in unnecessary maintenance costs or even a structural failure.

Objective of Soil Compaction

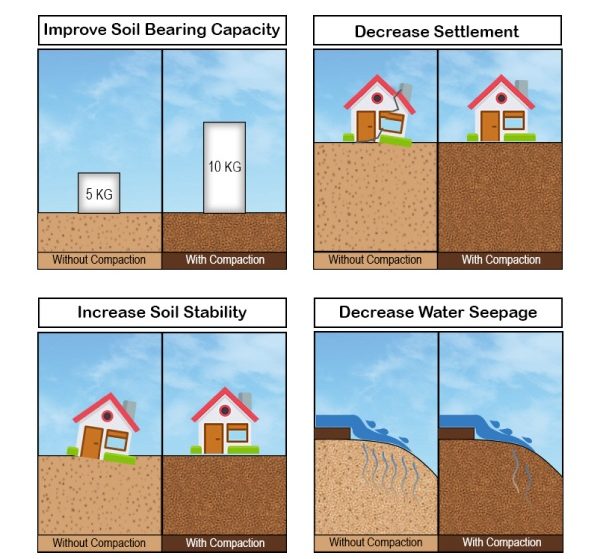

The main purpose of soil compaction is to improve engineering properties of soil by increasing its density, and to make it strong enough to resist displacement or movement under loads that may be applied to it.

01. Improve the load bearing capacity of soil

02. Increase soil strength

03. Reduction in the flow of water (Water seepage)

04. Decrease future settlement of foundation (Lower Compressibility)

05. Increase the shear strength of soil

06. Increase Soil Stability

07. Reduction in soil swelling (Expansion) and collapse (Soil Contraction)

Result of Poor Compaction of Soil

Improper compaction leads to,

- Cracking of pavements, floors and basements

- Structural distress from excessive differential and total settlements

- Structural damage to structures, water and sewer pipes and utility conduits

- Soil Erosion

Compactive Effort

The concept of compactive effort is used in both field and laboratory compactions. For laboratory conditions, compactive effort is defined as the application of a given amount of energy per unit volume of compacted soil. For field conditions, compactive effort is defined as the compaction obtained by using various equipments.

According to ‘P. Purushothama Raj’ (Author of book called Soil Mechanics & Foundation Engineering), Comapactive effort can be varied in the laboratory tests by changing the weight of the compacting hammer, number of blows per layer and number of layer. In vibratory method, the compactive effort can be changed by changing the frequency, amplitude and time of vibration.

In the field, compactive effort can be increased by increasing the number of passes of a roller. For all soils, both in the laboratory and in field compaction, an increase in compactive effort increases the dry density and decrease in the optimum moisture content.

Principles of Compaction

Soil compaction is the process whereby soil particles are forced to pack more closely together by reducing air voids. This is attained by applying some mechanical force (Static or dynamic loads) on the soil. The state of compaction of soil is measured by the dry density and the associated moulding water content.

The increase in the dry density of the soil produced by compaction depends on the water content of the soil and applied energy. For most soils and a given compactive effort, the density of the soil will increase to a certain point as the moisture content is increased. That point is called the maximum dry density. After that point, the density will decrease with any further increase in moisture content. The moisture content at which dry density is maximum is called optimum moisture content. Therefore, the maximum dry density occurs at an optimum moisture content.

Types of Soil Compaction

The process of soil compaction is merely removing the air from the voids or reducing air voids from the soil particles, causing more reduction in volume, which will result in adding more soil and hence the dry density will also increase accordingly.

Four types of basic mechanisms on which different types of compaction equipment work are:

01. Impact

It is a large force acting for a very short interval of time.

02. Pressure

It is a force acting on the unit contact area.

03. Vibration

It is a shaking force applied on the surface.

04. Kneading

It is manipulating or Rearrangement of the soil particles.

Soil Compaction Equipments

A variety of equipments are used to compact soils in the field. Static and vibratory vertical forces accomplish compaction. Several types of rollers are used for ordinary compaction in the field. The most common are

01. Smooth-wheel Rollers (or Smooth Drum Rollers)

The smooth-wheel roller can create vertical vibration during compaction. Also, they are suitable for sandy and clayey soils. However, they do not produce a uniform unit weight of compaction when used on thick layers.

If you want to know more detail about smooth wheel rollers as a compaction equipment read our blog: Compaction Equipment: Smooth Wheel Roller

02. Pneumatic Rubber-tired Rollers

Pneumatic Rubber-tired Rollers are better in many respects than smooth-wheel rollers. According to ‘Braja Das’ (Author of Book Called Principles of Foundation Engineering), they can be used for sandy and clayey soil, producing a combination of pressure and kneading action.

03. Sheepsfoot Rollers

Sheepfoot rollers consist of drums with large numbers of projections. The area of each of the projections is most effective in compacting the soil. They are suitable for cohesive soils.

04. Vibratory Rollers

Vibratory rollers are efficient in compacting the granular soils. Vibrators can be attached to smooth-wheel, pneumatic rubber-tired or sheep foot rollers to send vibrations into the soil to be compacted.

For more detail about vibratory rollers you can refer our another blog: Explain Vibratory Roller Compaction Equipments.

In general, compaction in the field depends on several factors such as the type of compactor, type of soil, moisture content, speed of the compactor and number of roller passes etc.

Variety of equipments use for compaction. But types of compaction equipments which are used in building project Refer our blog: Various Types of Compaction Equipment Use on Construction Site

Factors Affecting the Soil Compaction

There are many factors which affect the degree of compaction on the site. Let discuss few of them.

01. Nature and Type of Soil

The dry density of soil depends upon the type of soil. Coarse-grained soils can be compacted to higher level than fine-grained soils. Well-Graded sand attains a much higher dry density than poorly graded soils.

Cohesive soils have high air voids and attain a relatively lower maximum dry density as compared with the cohesionless soils. Such soil requires more water than cohesionless soil, and therefore optimum water content is high.

02. Water Content

At low water content, the soil is stiff and offer more resistance to compaction. As the water content is increased, the soil particles get lubricated. The mass of soil becomes more workable, and the particles have closer packing.

The dry density of the soil increases with an increase in the water content until the optimum water content is reached. The air voids attain approximately a constant volume at that stage.

03. Amount of Compaction

The amount of compaction greatly affects the maximum dry density and optimum water content of a given soil. The effect of increasing the compactive energy results in an increase in maximum dry density and decrease in the optimum water content.

04. Method of Compaction

The dry density depends not only upon the amount of compactive effort but also on the method of compaction. For the same amount of compactive effort, the dry density will depend upon whether the method of compaction utilizes static or kneading action.

Effect of Compaction on Soil Properties

The engineering properties of soils are improved by soil compaction. The desirable properties of soil are achieved by proper selection of the soil type, the mode of placement and the method of compaction. Let us discuss the effect of compaction on various soil properties.

01. Soil Structure

The water content at which the soil is compacted plays an essential role in the engineering properties of soil. Soil compacted at a water content less than the optimum water content generally have a flocculated structure. Soil compacted at a water content more than the optimum water content usually has a dispersed structure.

02. Permeability

The permeability of soil depends upon the size of voids. The permeability of a soil decrease with an increase in water content on the dry side of the optimum water content. The minimum permeability occurs at slightly above the optimum water content.

If compactive effort is increased, the permeability of the soil decrease due to increased dry density and better orientation of particles.

03. Swelling

A dry soil has high water deficiency and more random orientation of particles. It imbibes more water than the sample compacted wet of the optimum. Therefore, more swelling.

04. Pore Water Pressure

Pore water pressure is defined as the pressure of groundwater held within a rock or soil, in gaps between particles. The pore water pressure for soil compacted dry of the optimum is less than that for the wet of optimum.

05. Shrinkage

Soil compacted dry of optimum shrinks less when compared to compacted wet of optimum because the soil particles in the dispersed structure have nearly parallel orientation of particles and can pack more efficiently.

06. Compressibility

The flocculated structure developed on the dry side offers more excellent resistance to compression than the dispersed structure on the wet side. Consequently, the soils on the dry side are less compressible.

07. Stress-Strain Relationship

The soils compacted dry of the optimum have a steeper stress-strain curve than the wet side. The modulus of elasticity for the soils compacted dry of the optimum is high. Such soils have a brittle failure like dense sands or overconsolidated clays. The soils compacted wet of optimum have a relatively flatter stress-strain curve and a correspondingly lower value of the modulus of elasticity.

08. Shear Strength

At a given water content, the shear strength of the soil increases with an increase in the compactive efforts until a critical degree of saturation is reached. With further increase in the compactive effort, the shear strength will decreases.

Summing up, the soil close to the ground surface possessing sufficient bearing capacity shallow foundations are the best choice. However, where the topsoil is either loose of soft, the load from the superstructure has to transferred to deeper firm strata. In such a situation, pile foundations are the obvious choice.

There is another method which may, in some cases, prove more economical than deep foundations. This method is foundation soil improvement. Soil compaction is the oldest and most common method of soil improvement. It is the densification and reduction in the void ratio of soil through the explusion of air. Compaction of soil is a common practice to improve the various properties of soil.

The soil bearing capacity, settlement, shear strength etc. all depend on how well the soil is compacted. Compaction increases the soil’s strength and decreases compressibility and permeability. Also, it may control the characteristics of swelling and shrinkage.