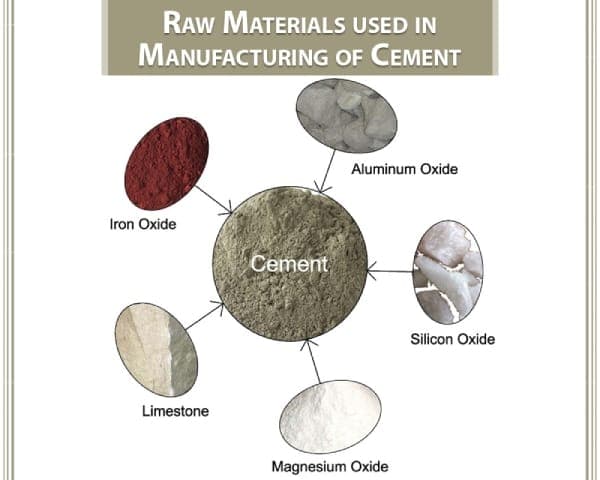

Raw materials used for manufacturing of Portland cement are found naturally in the earth’s crust. It is made primarily from calcareous and argillaceous materials and gypsum. Calcareous materials contain limestone or chalk while argillaceous materials comprise an oxide of silica-alumina and iron. Both are found as clay or shale. Let’s understand the various types of cement raw materials used in the cement manufacturing process.

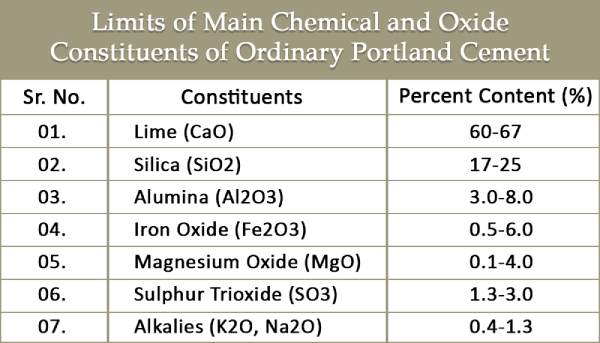

Limits of Main Chemical and Oxide Constituents of OPC are Given in this Table

Functions of the Constituents of OPC

01. Lime

It is the main constituent used in cement manufacturing. It is responsible for imparting the cementing property to cement. An excess quantity of lime causes expansion and disintegration of the cement. Deficiency of lime causes decreased strength and the cement sets quickly. If it is used in the right proportion, it makes the cement sound and strong. Thus, lime can drastically change the properties of cement.

02. Silica

This plays a major role in imparting strength to concrete. Silica undergoes a chemical reaction with calcium to form dicalcium silicate (C2S) and tricalcium silicates (C3S). Excess silica adds strength to cement but it prolongs the setting time.

03. Alumina

This forms complex compounds with silica and calcium to improve the setting capacity of the cement. It acts as a flux and lowers the clinkering temperature. Use of an excess amount of alumina quickens the setting time but reduces the strength of cement.

04. Iron Oxide

This is mainly responsible for imparting colour to cement. The hardness and strength of the cement are also improved to a certain extent. It helps in the fusion of raw materials during the cement manufacturing process.

05. Magnesium Oxide

It imparts strength to the cement when mixed in a small quantity; however, an excess amount makes the cement unsound.

06. Sulphur Trioxide

This makes the cement sound if present in small quantity but an excess can make the cement unsound.

Cement is sometimes blended with other cementitious and/or a special material. This cement is called blended cement. They are produced by properly blending two or more types of cementitious materials and cement raw materials. Generally, the primary blending materials are fly ash, ground granulated blast furnace slag (GGBS), silica fume, and natural pozzolana.