The non-destructive tests are the group of useful methods to evaluate the strength of construction materials without causing damage. It is not always possible to do destructive tests for the materials of construction like concrete, block and clay bricks, etc. particularly when they are already laid. They are independent tests sufficient to make the structural engineering decisions after establishing figurative substantiation through its application. Rebound hammer test procedure is used to examine the hardness of concrete particularly when you want to carry out repairs of RCC structure.

We have already discussed the points which affect the rebound hammer test results. We have also discussed the use of rebound hammer test and its limitations. Here are the procedure of rebound hammer test and precaution while performing the test. We also discuss the rebound hammer graph which shows the correlation between the compressive strength of concrete and rebound number.

What is Rebound Hammer?

Rebound hammer is an instrument or a device, which is used to assess the relative compressive strength of concrete based on the hardness at or near its exposed surface. Rebound hammer is also known as Schmidt’s Hammer or Swiss Hammer as it is invented by Ernst Schmidt, a Swiss engineer.

Rebound Hammer Test Procedure:

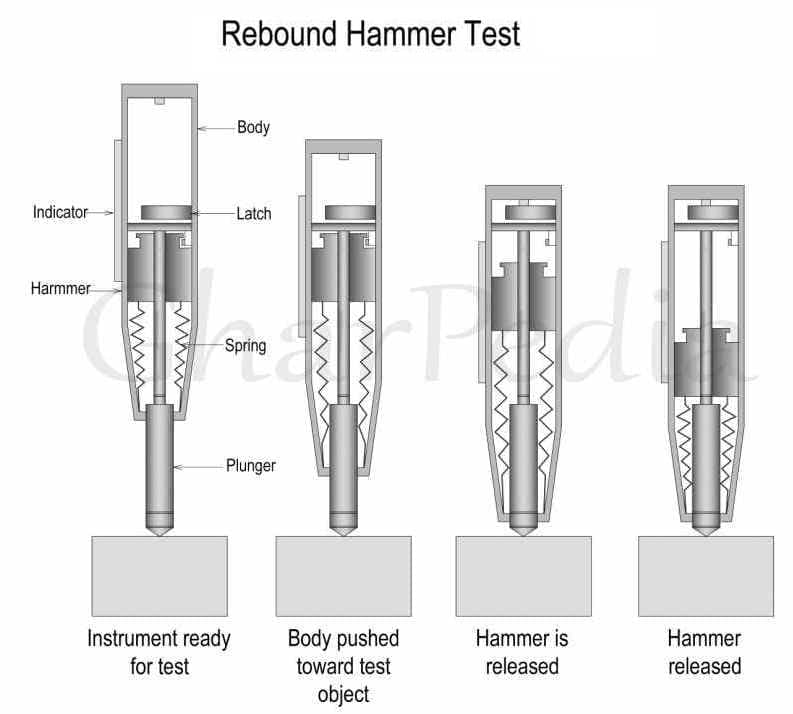

In the procedure of rebound hammer test, the plunger of rebound hammer is pressed on the surface of concrete, so that a spring controlled mass with a constant energy is made to hit the concrete surface. At the same time, a spring controlled mass rebounds back. This extent of rebound on a graduated scale is measured for the surface hardness. This measured value is designated as Rebound Number or a Rebound Index.

RCC structures having concrete with low compressive strength and low stiffness has a lower rebound number or rebound index. Average of six reading should be taken for each point of testing for the rebound number.

Which Precautions are Needed to Take care while Carrying out Rebound Hammer Test Procedure?

- The surface should be smooth, clean and dry.

- The loose surface should be rubbed off with a grinding wheel or stone, before testing.

- The point of impact should be at least 20mm away from the edge or sharp discontinuity.

- The test should not be conducted on the rough surface resulting from incomplete compaction of concrete, loss of grout, spoiled or tooled surface.

IS 13311 (Part 2): 1992, BS 6089-81 and BS 1881-202 explains the standard rebound hammer test procedure.

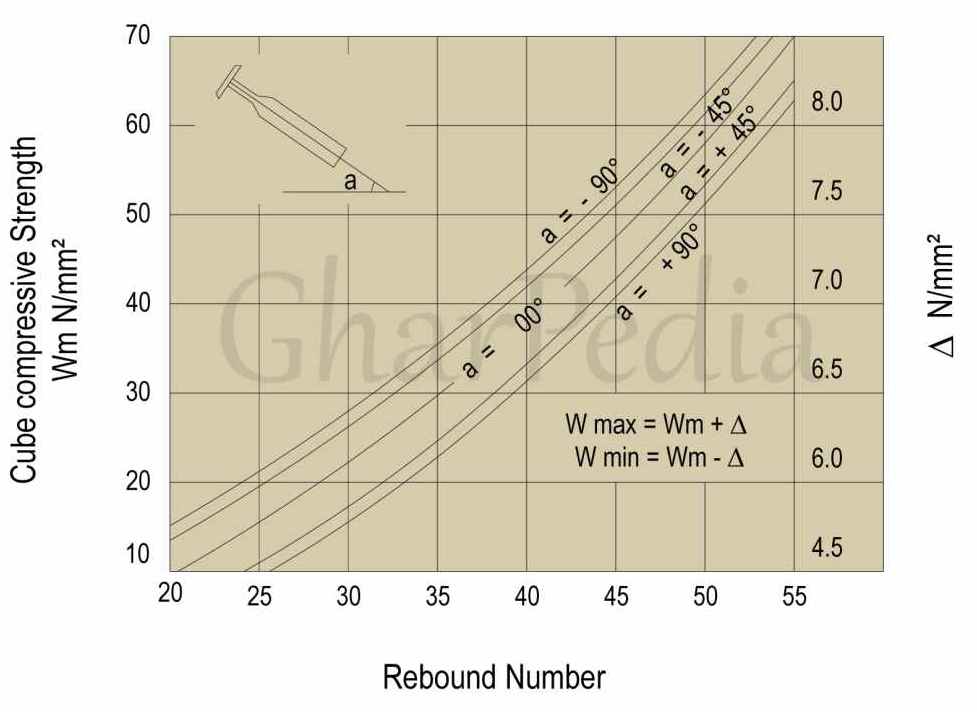

The compressive strength can be evaluated directly from the graph provided on the body of the hammer.

What is Rebound Hammer Test Graph?

Rebound hammer test graph describes the correlation between the strength of concrete and rebound number. Where “a” is the angle of the position of rebound hammer device. Always use rebound hammer perpendicular to the plane of a concrete component or any other materials.

It is necessary to calibrate the rebound hammer before carrying out the test on hardened concrete. The suitable methods for checking the calibration of the rebound hammer is to test the concrete cube of size (150mm * 150mm * 150mm) with the help of rebound hammer and then with the compression testing machine (CTM). If the strength results of rebound hammer test exactly match with CTM results, then it is ready to use. But if the major difference found in results, then we need to calibrate the rebound hammer before testing.

How to Check the Quality of Concrete Based on Rebound Number?

The table below shows the quality of concrete based on the average rebound number or rebound index.

| Average Rebound Number | Quality of Concrete |

| > 40 | Very Good |

| 30 -40 | Good |

| 20-30 | Fair |

| < 20 | Poor and/or Delaminated |

| 0 | Very Poor and/or Delaminated |

Rebound hammer test procedure depends on many points that influence the results of the test. The concrete strength will be valid only if they are all standardised for the concrete under test and for the calibration specimens. Thus the engineer has to use his common sense for carrying various tests in combination and make the judgement before determining any repairing or strengthening proposals.

Also Read:

Non-Destructive Concrete Tests for Structure Strength

Ultrasonic Pulse Velocity Test