Traditionally, brickwork is the construction technology for constructing walls. The brick wall can be defined as systematically laying of bricks in a house for obstruction, separation and safety purposes. Furthermore, this obstruction provides safety and privacy to the homeowner.

A brick wall separates the home user from the outer environment. House owners get nervous when they find the active or inactive cracks in brickwork as they are the main reason of maintenance and repairing work. If the Home owner knows the way for investigation and repairing of cracks in brickwork then he can reduce the cost of maintenance and repairing. In this article, we provide necessary information regarding the investigation and repairing of the cracks in brickwork.

We have already described the Major Causes that Influences the Cracks in Building. We have also described horizontal cracks in brick walls, vertical cracks in brick walls and diagonal cracks in brick walls for the load bearing as well as for infill walls of RCC frame structure. Here are the best way for investigating and repairing cracks in the brickwork of load bearing as well as infill walls/panel walls of RCC Structures. Cracks can always be structural or non-structural.

Investigation of Cracks in Brickwork:

Investigation of the cracks in the wall is a very tough job. The owner needs to spend time toward the investigation of cracks as every homeowner dreams of the crack free home.

01. Data Collection And Records:

The owner needs to collect the data like the year of construction, quality and specification used for construction materials, the brickwork methodology, and details of the additions or alterations of the house during its life.

It is necessary to maintain records of all the documents related to your home as this document helps to defeat your future problems.

02. Check The Behavior Of Cracks:

Check the behavior of the cracks by monitoring the progress of cracking whether they are active cracks or inactive cracks (passive cracks) in brickwork.

Measure the extent of widening or lengthening by fixing the standard tell-tale crack monitoring gauge. The tell-tale crack monitor is a device, which is used for internal or external cracks, and it monitors the opening and closing of cracks with an accuracy of 1 mm. The tell-tale device consists of glass strip about 2 to 3 cm in width and 10 to 12 cm in length. Crack width gauge is specifically designed to measure the width of the cracks.

Another way to easily identify the crack by your self is using butter paper method. Where ever the crack is visible simply stick the butter paper with ordinary gum along the length of the crack and wait till crack develops. If the butter paper gets torn along the cracks over a period of time then it can be easily said that the crack is active and expanding and hence it can’t be ignored.

- Observe the defects in the paint, plaster, etc. Also, observe brickwork cracks, whether they are deep throughout the thickness in masonry or appears only at the surface.

Some cracks might be in paint film, and some may be in plaster and that too on one side only. But the one which is through and on both sides needs immediate attention.

Note the start and end point. Check the cracks, whether they have any relation with door and window opening.

- Observe the cracks in the brick wall, whether they start above the plinth level or pass through DPC or they extend right up to the foundation. Cracks in the foundation are difficult to repair as they are below the ground level and for repairing you need to open foundation, which is risky.

- Furthermore, note the geometries, patterns, nature, width and shape of cracks.

- It is also important to observe the environmental effect like dampness in the building and building exposure to the sun.

Repairing of Cracks in Brickwork:

The main purpose of the crack repairing in the brick wall is to restore the original appearance and strength of the brick wall. As a matter of fact, repairing of cracked wall also minimises the possibility of further damage to the building. Furthermore, repairing of cracks ensures the future service life and safety of the building.

01. Dormant Crack Repairing or Inactive Crack Repairing:

Repair the dormant cracks in the wall by raking the joint and filling with mortar of CM 1:6 which contains synthetic fibres. Dormant cracks are known as inactive cracks. They are also called passive cracks.

02. Active Cracks Repairing:

Always remember that, when there is an active crack due to thermal movement, no useful purpose is served in repairing cracks as they will reappear after some time.

(a) Repairing of Cracks in Brick Wall (Crack Width Less Than 2 mm):

If the cracks are less than 2 mm in width, then repair the crack by applying the Snowfilla paint (ACC make) which is expanding in the cracks when it dries. The application of Snowfilla paint is same as the application of putty for the painting work. Remember to cure painted crack for at least five days.

(b) Repairing of Cracks in Brickwork (Crack Width Between 2 mm to 5 mm):

If the cracks are between 2 mm to 5 mm in width, then repair the crack by injecting the flowing grout in the proportion of cement 1 kg, grout polymer 0.1 kg, and 1-litre water. Drill the hole at a spacing of 350 mm c/c for fixing the nipple with the sealant. Use pressure pump for injecting the grout mixture with the pressure of 3 kg/cm2.

(c) Repairing The Cracks In Brickwork (Crack Width Between 5 mm To 10 mm):

If the cracks are between 5 mm to 10 mm in width, then remove all the loose materials and make the groove of cracks 25 mm wide and 10 mm deep. Remove the plaster up to a width of 300 mm on the both sides of the cracks and fill the groove with CM 1:3 with 10% polymer by weight of cement. After the cracks have been filled, 12 mm diameter nipples shall be inserted at 100 mm c/c and 30 mm to 40 mm deep along the crack line and use the above grouting method for grouting the cracks.

(d) Repairing of Cracks in Brick Masonry (Crack width greater than 10 mm):

Remove all the loose materials from the crack and remove the plaster up to 450 mm on both side of the cracks. Fill the cracks with CM 1:3 with 10% polymer by weight of cement.

Furthermore, fix the weld wire mesh of galvanised steel wire fabric 3 mm thick and welded by square of 50 mm * 50 mm on both side of the wall and stretched and fixed with nails.

Use the crack stitching method for repairing of wall cracks which are wider than 1 mm in width. Fix the M.S clamps of 8 mm diameter bars at 600 c/c after drilling through hole in the wall and tie the same with nuts and washers. Grout the clamps with cement slurry grout in the proportion of cement 1 kg, grout polymer 0.1 kg and water sufficient to make flowing grout. Inject it with the pressure of 3 kg/cm2.

Finally, apply the first layer of cement plaster of CM 1:2 in 15 mm thickness and second layer of cement plaster 20 mm thick in CM 1:3 in double coat plaster which should be be matched with the existing surface.

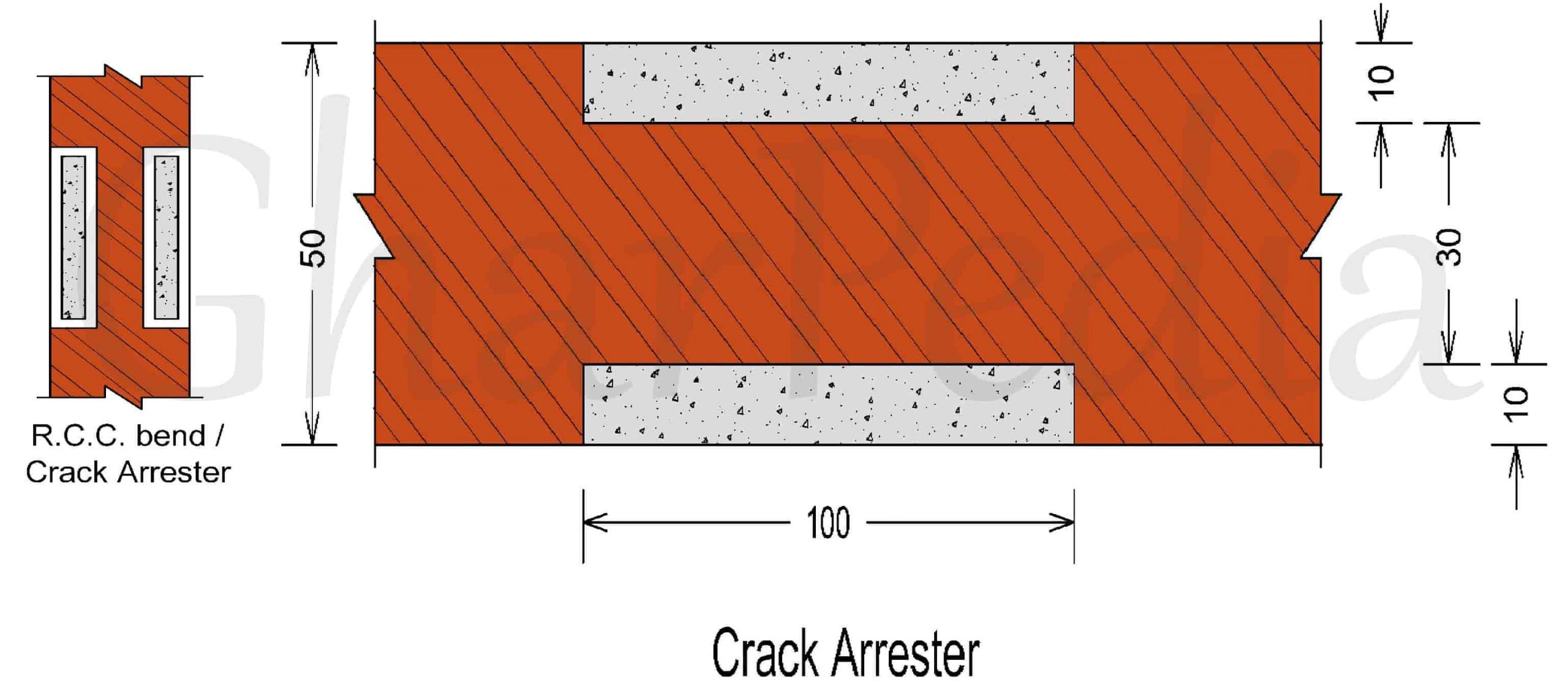

Crack Arrester For Active Cracks:

Provide the RCC band or crack arrester across the line of an active crack which arrests the crack and prevents further cracking.

Crack arrester is the component which is placed on both exposed surface of the wall. The thickness of the crack arrester should be equal to one-third the thickness of the wall.

Crack arrester is a vertical composite section of brickwork and concrete based on the principle of a flitched column. Place the reinforcement mesh and fill the cracks in brickwork with good quality concrete. Repeat this procedure on both sides of the wall.

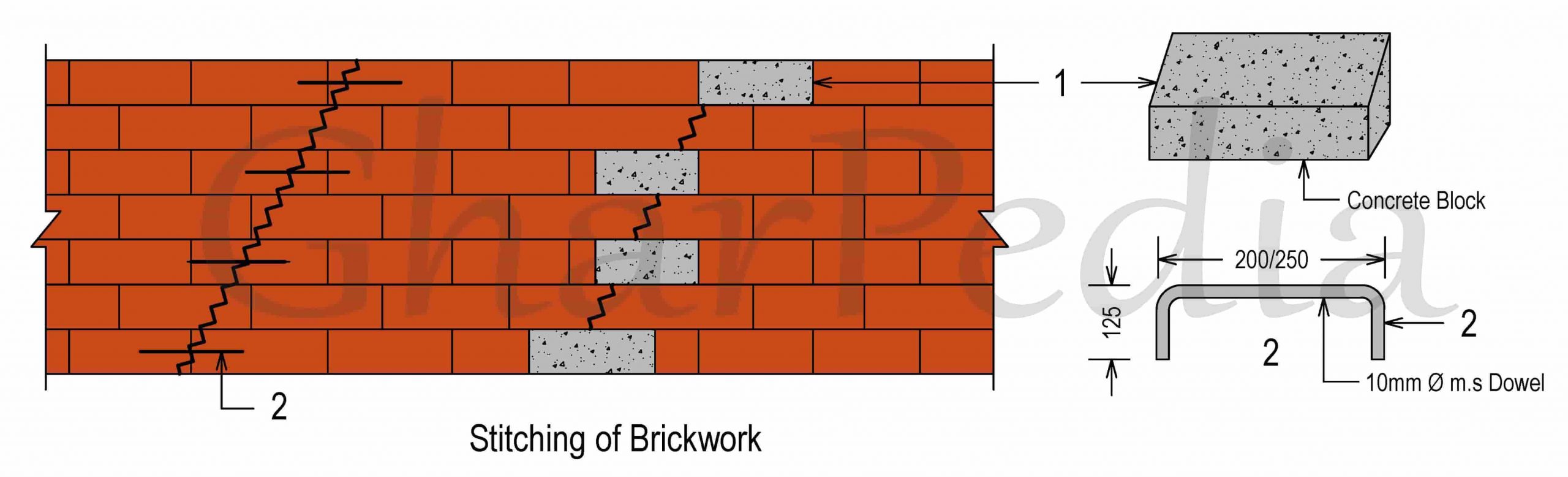

Different Types of Stitching Methods:

Stitching methods are used in the case of wide diagonal cracks in brick wall which occurs due to the settlement of foundation. If there is the possibility of further cracking, then carry out repair by removing and replacing all cracked bricks. Adopt following types of stitching methods Procedure.

Insert precast cement concrete blocks of common size 250*125*75 mm which is cast with cement concrete 1:11/2:3 in the first stitching method. Holes are cut to the size of brick with depth 125 mm. The cement concrete blocks are set into the holes with mortar at alternate layers of brickwork along the line of crack. You can carry out plaster work after curing period.

- Insert MS U-shaped dowel bars of diameter 8 mm or 10 mm or as per requirement and of 200 to 250 mm length with legs of 125 mm. Chase the crack and drill the hole for insertion of the dowels bar with legs inside. Ensure that the top of the U is at least 20 mm below the brick surface. The chase is then filled with cement concrete 1:11/2:3 with 5 mm down grit. When the insertion of the dowels is complete, the surface is plastered.

- Insert the RCC stitching blocks of mix 1:2:4 with the provision of reinforcement. The length of the block is equal to 1 to 2 bricks, thickness equal to 1 to 2 brick and width equal to thickness of the wall.

Remove and replace the cracked bricks by RCC stitching blocks in every 5th or 6th course or at about 500 mm spacing in the vertical direction of crack length. Replace the remaining other courses with good quality ordinary bricks.

03. Repairing Of Separation Cracks in Brickwork:

Separation cracks between column and brick work or beam and brick wall is the major problem

In the case of separation cracks observed at the junction of members of two different materials, it should be repaired by filling the cracks with the appropriate flexible material like mastic compounds.

Fix the chicken wire mesh over the separation crack and re-plaster it which stops the further cracking between the RCC member and brickwork or between brickwork and wooden frame.

04. Repairing Of Heavy Cracks In Brickwork:

Heavy cracks in brickwork occur due to the settlement of foundation, In such cases, consider brickwork to be beyond repair and it needs careful replacement. Arrange the supporting system for the slab and check weather all the loads are transferred on the props supporting system. Demolish the brickwork partly and then rebuilt. It is advisable to consult first your engineer before starting the demolition work.

In conclusion, if the cracks are wider then use cement concrete of mix 1:11/2:3 with 5 mm grit. You can also use mastic compound for filling cracks in brickwork. Furthermore, use the bituminous compound for filling the thin cracks in brickwork when the concrete or mortar raises the difficulty of deep self-penetration. In short, just don’t try to fill the cracks in brickwork with rich cement sand mortar.