Do you know the fundamentals of steel corrosion in concrete? When the steel is surrounded by concrete layer, hydrated cement provides an alkaline environment at which concrete pH is around 12.6. It helps steel to form the passive film on the surface of the steel. The passive film protects the reinforcement steel from the corrosion. Thus concrete cover provides protection to the steel. Steel corrosion in concrete starts when the protective layer of steel is broke down by a carbonation or ingress of chlorides iron in the hardened concrete.

The steel corrosion in concrete is either in localised form or generalised form. The generalised steel corrosion is due to the expansion of rusting steel which is very disruptive. The steel corrosion in concrete is also formed due to sulphate attack, and efflorescence (leaching). It is also formed due to decalcification, sea water, bacterial corrosion, thermal and radiation damages.

Corrosion risk classification at different chloride levels:

| Sr. No. | Chloride Content (% weight of cement) | Risk of corrosion |

| 01. | 0.4 | Negligible |

| 02. | 0.4 to 1.0 | Possible |

| 03. | 1.0 to 2.0 | Probable |

| 04. | >2.0 | Certain |

Learn More tests which are used to examine the hardened concrete.

Rebound Hammer Test Procedure

Ultrasonic Testing Procedure

Concrete Pull Out Test

Carbonation Test

Chloride Content Test

Concrete Core Test

Here are the needs, principles and methods of different tests for the risk assessment of the steel corrosion in concrete.

Steel Corrosion in Concrete Needs to be Tested:

- To identify the risk of corrosion which may not appear on the concrete surface

- To identify the extent of corrosion which is partially observed at the concrete surface

- To assess the integrity of reinforced concrete structure which experiences the reinforcement corrosion.

Principles of Steel Corrosion Testing:

Steel corrosion in concrete is an electrochemical process which involves the establishment of rusting. It leads to the development of regions of differing electrical potential and current flow within the concrete. It is a measurement of the potentials and magnitude of corrosion current flow within the concrete.

Testing Methods of Steel Corrosion in Concrete:

01. Cover Meter Method or Profometer Measuring Method:

Image Courtesy – proceq

Cover meter method and profometer measuring methods both are the same non-destructive methods. They are used for testing of steel corrosion in concrete.

They Measures:

- The thickness of cover to concrete with an accuracy of 5 mm

- Reinforcement diameter

- Reinforcement Spacing

In cover meter method, reinforcement bar can be located up to 300 mm depth with the help of cover meter or profometer instruments. The reliable cover estimates may only be made for single bars up to 100 mm concrete thickness.

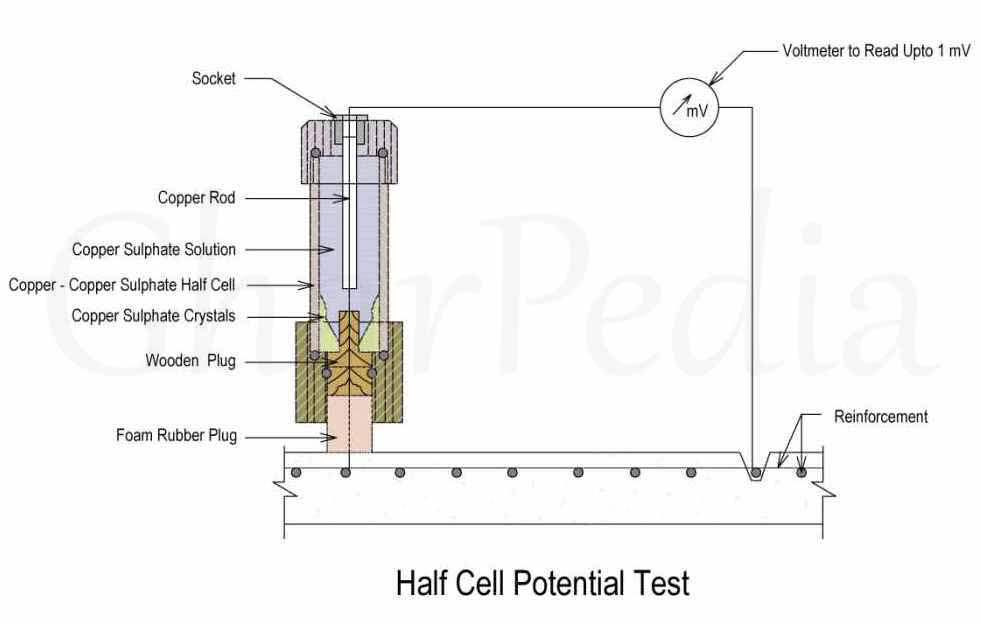

02. Half-Cell Method:

Image Courtesy – giatecscientific

This non-destructive test is used for measuring or plotting corrosion potential. The corrosion potential is used for assessing the probability of steel corrosion in concrete. The Half-Cell Potential method is also used for finding out the status of steel corrosion in concrete in the sense of active or not.

Half-cell method involves measuring the potential of an embedded reinforcement bar relative to a reference half-cell like copper sulphate cell or silver chloride cell placed on the concrete surface.

The concrete acts like an electrolyte. The risk of steel corrosion in concrete may be empirically related to the measured potential difference.

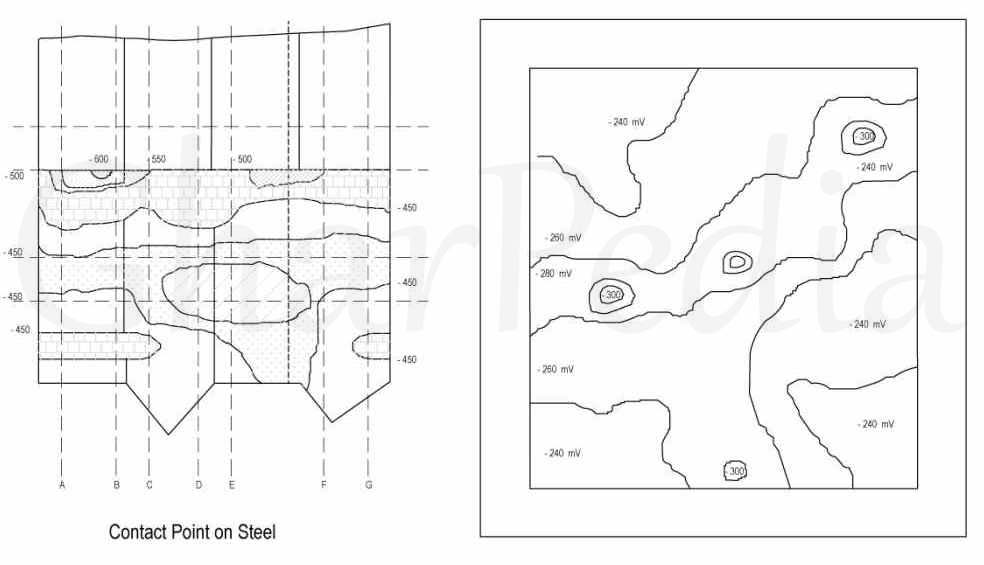

In Half-Cell Method, the equipment enables NDT survey to produce half cell potential contour maps of the concrete surface. Contour maps indicate the degree of steel corrosion risk.

| Sr. No. | Half-cell Potential (mV) | Probability of Corrosion |

|---|---|---|

| 01. | >-200 | 10% |

| 02. | -200 to -350 | 50% |

| 03. | <-350 | 90% |

Nowadays the equipment includes multi-cell and wheel devices. They are available with automatic data logging & graphical output.

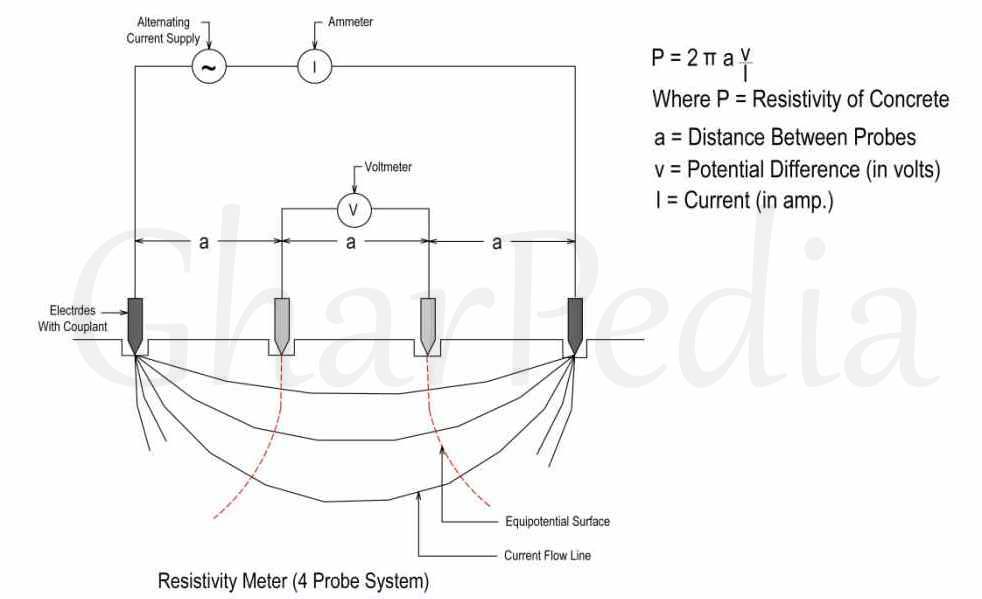

03. Resistivity Measurement Method or Electrical Resistivity Method:

Image Courtesy – img.directindustry

Concrete Resistivity Measurement method is used for assessing electrical resistivity due to steel corrosion in concrete. In resistivity measurement method, the measurements are made using a Wenner four probe procedure.

In Electrical Resistivity Method, four electrodes (Probes) are arranged in a straight line. Furthermore, it is positioned just below the concrete surface with an equal interval/spacing. The alternating current is passed through the outer electrodes. Measure the drop voltage between the inner electrodes at the same time.

Calculate the resistivity from that measurement. The resistivity can be related to steel corrosion hazard. The probability of steel corrosion in concrete may be predicted where half-cell potential measurements show that corrosion is possible.

Nowadays the equipment includes automatic data logging. It is also includes spring loaded automatic couplant dispensers for surface use.

Linear polarisation resistance equipment is used to predict the rate of steel corrosion in concrete. This equipment is relatively expensive.

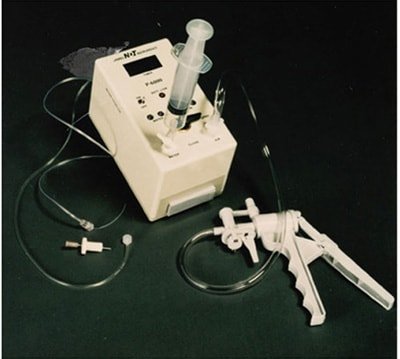

04. Concrete Permeability Test:

This test is used for the assessment of in-situ permeability of concrete due to water and air.

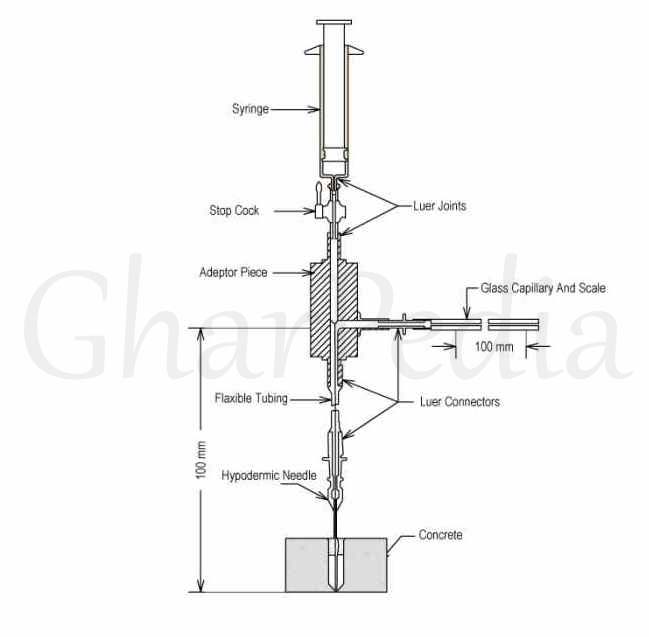

There are two methods of concrete permeability test, named Clam method and Figg’s method (Poroscope method) to check the permeability of the concrete. The permeability of the concrete affects the steel corrosion in concrete.

Image Courtesy – azom

In Calm Method, the volume of water entering concrete surface at low or high pressure is measured for 20 minutes in the water test. In the air test, the pressure up to 1.5 bars is created and the decay of pressure recorded over a 20 minute period.

In Figg’s method, water is forced by a syringe through a needle into the void of concrete and connected to horizontal capillary set at a head of 100 mm. The time for absorption of 0.01ml water is measured in the water test. In the air test, a vacuum of 55 KPa below atmospheric is created in the void by hand pump and time for a 5 KPa rise to occur is measured.

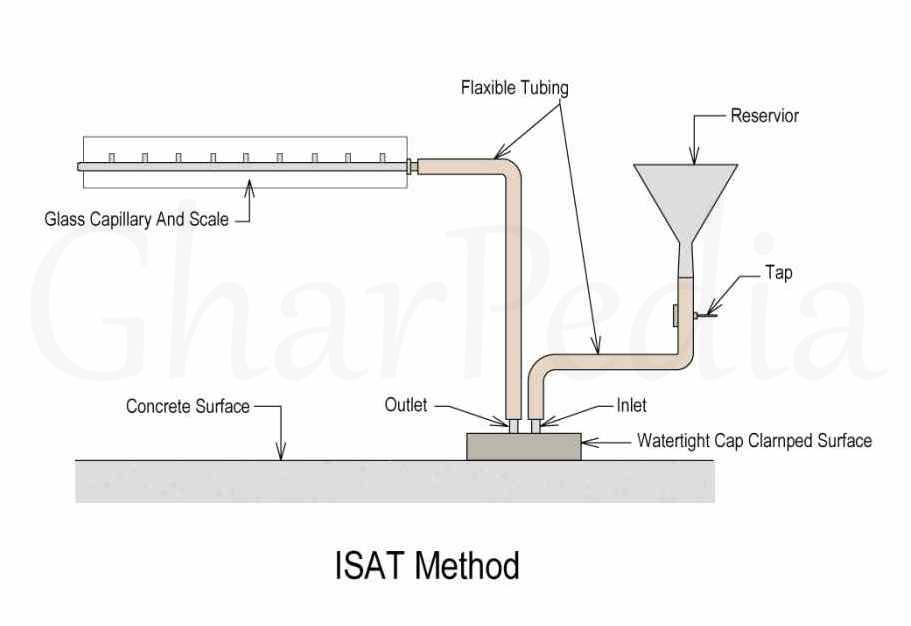

05. Initial Surface Absorption Test ( ISAT Method):

Initial Surface Absorption test (ISTA Method) is an indicator of surface permeability, and it is performed in the laboratory. ISAT Method involves the measurement of the rate of flow of water per unit area in a concrete surface when subjected to a constant water head. A cap is fixed to the concrete surface to provide water contact of at least 5000mm2 and connected to the reservoir. Horizontal capillary tube and scale should be calibrated first. The opening/closing tap between cap and reservoir is closed. Movement of the water in the capillary is measured at regular intervals from the start of the test.

In conclusion, it is necessary to identify the risk of the steel corrosion in the concrete structure. Steel corrosion in concrete may lead to structural weakening by the loss of area of steel, by cracking and spalling concrete. Furthermore, steel corrosion in concrete may also lead to structural weakening by Internal delamination. As a matter of fact, the homeowner needs to understand above tests properly. They are very useful for the risk assessment of steel corrosion in the concrete structure.

We have already discussed the tips which helps to prepare the reinforcement steel before repairing of corrosion damaged concrete. Also read right steps for repairing of concrete.

Must Read:

Uses of Rebound Hammer Test and its Limitations

Ultrasonic Inspection

Factors Affecting Ultrasonic Test