Sheet Glass

Definition:

Glass drawn from a molten bath into a thin sheet of film.

or

Glass formed into large thin sheets is known as Sheet Glass.

Composition:

Roughly composed of:

- 100 parts of sand,

- 35 parts of chalk or lime stone,

- 40 parts of soda,

- 50 parts of broken glass, which act as a Cullet.

Origin:

Origin of Sheet Glass was in 1795-1805.

Image Courtesy – 123rf

Manufacturing Process:

- Molten glass is forced by hydrostatic pressure through a narrow slit on a fire clay float.

- Glass is drawn from the slit as a sheet of viscous liquid.

- As soon as it becomes solid, it is passed through asbestos covered rollers.

- The sheet is then cut in required length.

Use:

a) Glazing of

- doors,

- Windows,

- Ventilators,Sky lights.

- Sky lights.

Size & Thickness:

- Available in thickness from 2 mm to 6.5 mm

- Size up to 110 to 175 cm.

- Produced in 3 classes

a) Ordinary Glazing Quality

b) Selected Glazing Quality

c) Special Selected Quality

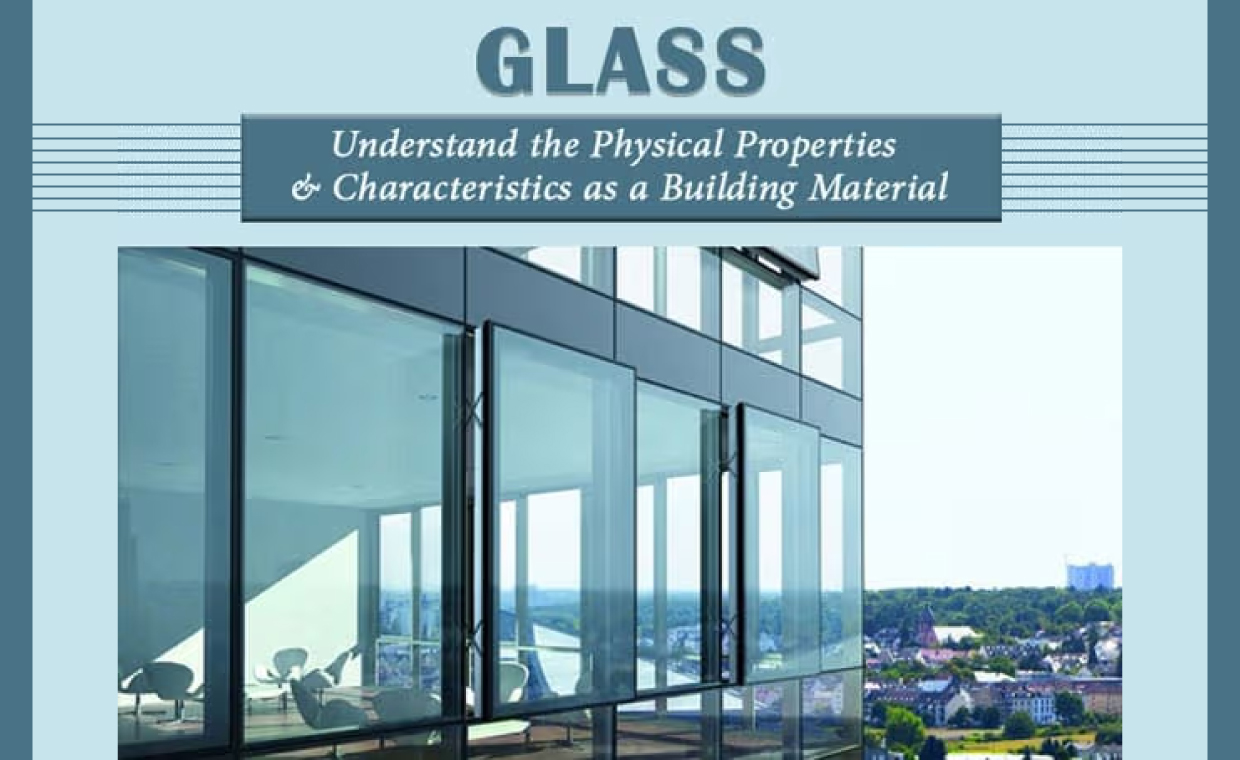

Plate Glass

Definition:

Strong rolled and polished glass containing few impurities.

It is stronger and more transparent then Sheet Glass.

Origin:

Origin of Plate Glass was in 1720-1730.

Image Courtesy- 123rf

Manufacturing Process:

- It is formed by taking the molten glass from tank into a ladle and pouring on to a cast iron table where it is rolled into a sheet.

- The rolled plate is annealed, ground and polished on both sides.

Use:

a) Glazing of

- Doors,

- Windows,

- Ventilators,

- Sky lights

- Mirror / Reflector

Size & Thickness:

- Available in thickness from 3mm to 32mm

- Size up to 90 to 275 cm.

Types:

Produced in 3 classes

01. S.G. Quality ( General Glazing)

a) Used for cabinets, show cases, shop fronts, counters, and shelves table tops, scale counter, aquariums.

02. S.G. Quality (Selected Glazing)

b) Mostly used in making mirrors.

03. S.Q. Quality (Special Glazing)

c) Superior quality for high class work