Table of Contents

Quick Summary

- The use of glass as a building material is increasing with the rise of contemporary architecture and interior design.

- Glass is a fragile material; however, with modern technology, its characteristics and properties can be improved to the extent that today we even have bulletproof glass.

- The main characteristics of glass are hardness, brittleness, weather resistance, insulation, chemical resistance, transparency, and property modification.

- The surface modification processes of glass include anti-fog coating, anti-reflective coating, chemically strengthened glass, anti-corrosion coating, hydrogen darkening layer, and many others.

- The properties of glass as a building material include its density, compressive strength, tensile strength, Young’s modulus, Poisson’s ratio, and coefficient of thermal expansion.

According to ‘James Stevens Curl & Susan Wilson’ (Authors of The Oxford Dictionary of architecture), “glass is a semi- or fully transparent hard, brittle, lustrous material made by igneous fusion of silica (usually sand) with an alkaline sodium or potassium salt and added ingredients. It appears to have come into use for glazing the windows of grander buildings during the Roman Empire.” Based on the important characteristics & properties of glass, it is considered as the best future material in building construction.

There is a predominant use of glass in contemporary architecture as there is an increasing demand for transparent building elements. Traditionally, glass was used a as single pane in concurrence with a load carrying frame. But if we see today, glass as a building material is also used as a primary structural member in the form of glass fins, walls and beams.

According to ‘Laufs Wilfried & Luible Andreas’ (2003) (Published in Introduction on use of glass in modern buildings), Glass is a magical building material as it has various applications in doors, windows and building façades depending on its characteristics & properties. It offers people varied choices depending on factors like safety, security, functions related to the environment (self-cleaning, sunlight and heat transparency, visibility) and qualities like scratch resistance etc.

Characteristics of Glass as a Building Material

Following are the properties and characteristics of the glass.

01. Hardness and Brittleness

It is a hard material and has great impact resistance against applied load. However, at the same time, it is a brittle material as it breaks immediately when subjected to load.

02. Weather Resistance

It is weather resistant as it can withstand the backlash of rain, sun and wind. It can absorb, reflect and refract light as it enables us to control and manipulate natural light to influence our daily activities and regulate our mental and physical health. It has great dimensional stability and low thermal expansion value. (i.e. its change in volume with respect to temperature change as compared to other materials is very low.)

03. Insulation

It is an excellent insulator against heat, electricity and electromagnetic radiation because of its good insulating response against visible light transmission.

Certain special type of glass has high resistance against ultra-violet, infrared and x-ray transmission. It has an excellent resistance against sound transmission provided used with appropriate thickness.

04. Chemical Resistance

It can withstand the effect of the chemical reaction under different environment conditions or acidic effects.

It has excellent resistance to most chemicals including solutions of inorganic alkalis and acids such as ammonia and sulfuric acid.

05. Colour and Shape Varieties

It can be blown, drawn and pressed to any colour, shape, and variety and is available in the market depending upon their use, dimensional requirements, and safety requirement.

06. Transparency

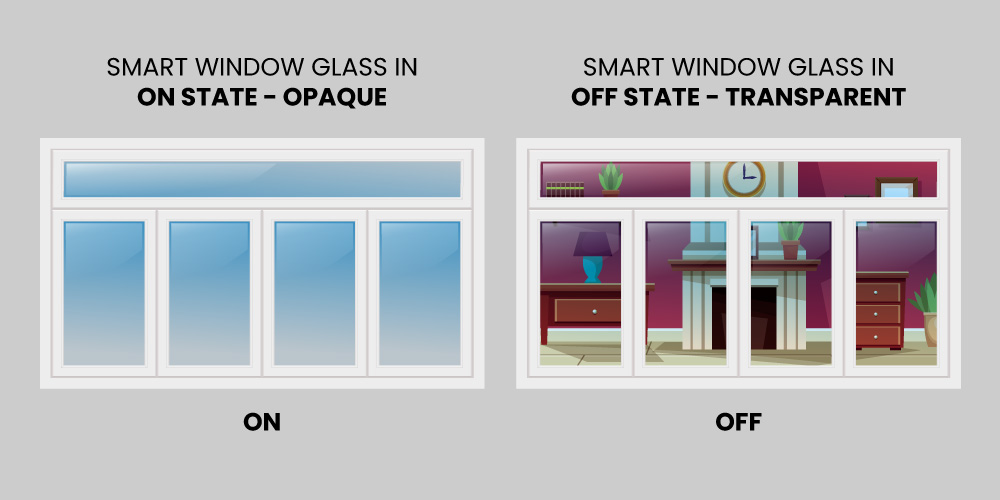

The transparency is one such property of glass which creates a visual connect with the outside world. With the advent of technology, clear glass can also be altered, making it opaque.

07. Fire Resistant Glazing

According to ‘Laufs Wilfried & Luible Andreas’ (2003), Modern glazing products allow fire protection up to 120 minutes. The transparent glazing is protective by becoming opaque if it is subjected to above 120°C. This is achieved with the help of special transparent gels. (Published in Introduction on use of glass in modern buildings).

08. Property Modification

It is also possible to change some of its properties to suit different purposes. The major surface modification processes are listed below, and their names itself suggest the different properties of glass to which it can be modified depending upon their use in the building.

List of Surface Modification Process of Glass:

(a) Anti-Fog Coating:

It is an anti-fog treatment that reduces water droplets’ surface tension, which causes them to disperse in an invisible thin sheet. This sheet provides a clear and fog free vision.

(b) Anti-Reflective Coating:

It is the treatment to reduce reflection. It produces less glare. Many coatings consist of thin transparent thin films with alternate layers of contrasting refractive index.

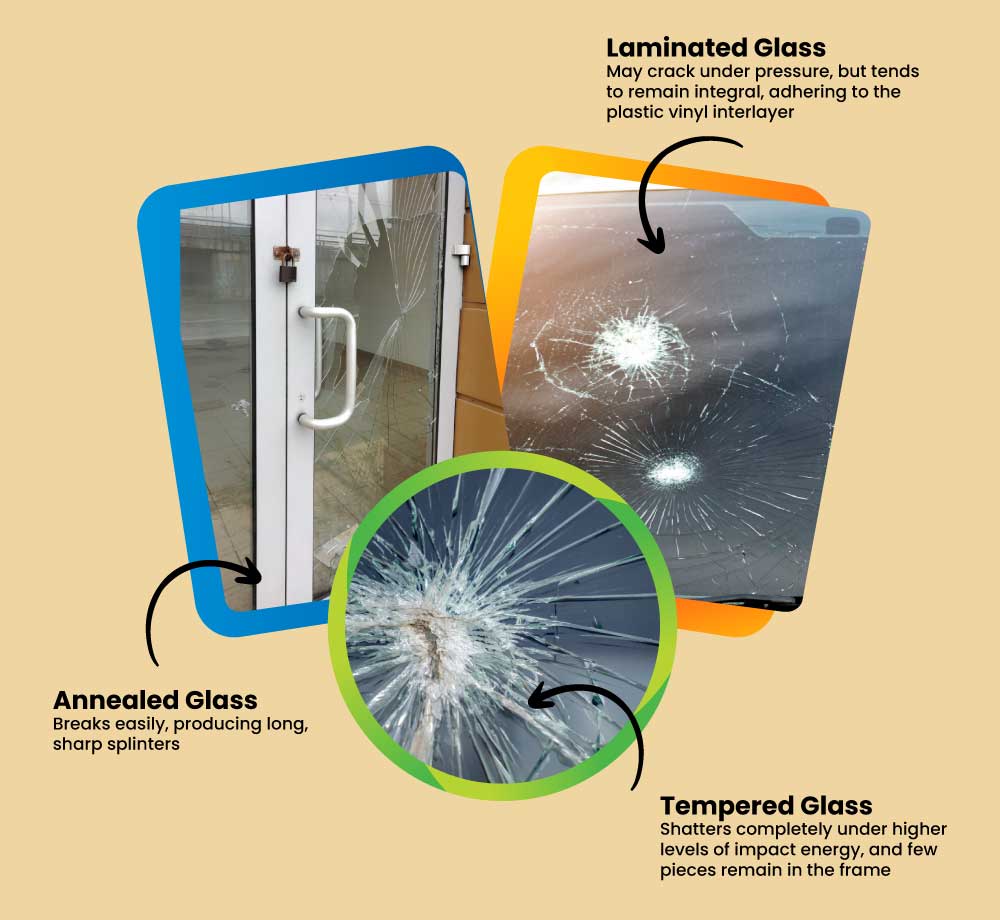

(c) Chemically Strengthened Glass:

It is a surface treatment occurring at a temperature lower than glass melting temperature. It includes safety glass, toughened glass, wire-mesh glass, and laminated glass. Additionally, in the case of breakage, it breaks into bigger pieces, not as sharp as that of non-toughened glass. But in case of laminated glass, it holds the glass pieces together, when shattered. It is held in place due to an inter layer, between 2 layers of glass.

It offers an improved resistance to scratching, impact, and has bending strength and increased temperature stability. Wired glass prevents glass from falling at the time of fire emergencies.

(d) Anti-Corrosion Coating:

It helps to protect the surface of glass by preventing corrosion due to contaminants like water, heat and humidity. Thus, it is resistant to water.

(e) De-Alkalization Coating:

It is a process of surface modification which is applicable to glasses having alkali ions. Here, a thin surface is created containing a lower concentration of alkali ions than originally present. This change in surface composition changes the properties of the surface, thus enhancing resistance to corrosion.

(f) Hydrogen Darkening Layer:

It is a chemical process that interferes the passage of light.

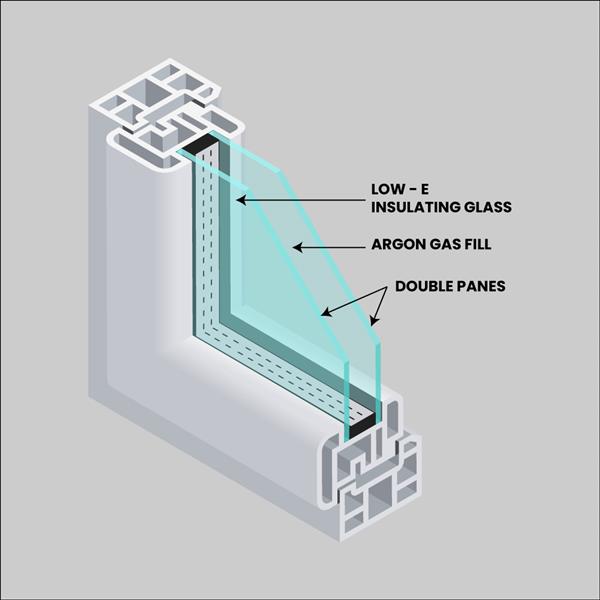

(g) Insulated Coating or Double Glazing or Double Pane:

It consists of two or three layers of glass separated by vacuum or gas filled space to reduce heat transfer through the building envelope. It is specifically used for heat or sound insulation for both low and high frequency sounds.

(h) Sand Blasting and Acid Etching Process (Frosted Glass):

The acid etching treatment is a permanent chemical process that gives a velvety and soft touch to the glass, significantly reducing its transparency, but not the light transmission. It is an old method of imprinting images on glass.

Sandblasting is the process of blasting the surface of glass with sand which peppers the surface, giving it a milky white appearance. It is generally done with a high-speed machine bombarding the glass panel with sand.

(i) Low Emissivity Coating:

It allows to minimize the amount of infrared and ultraviolet light that comes through your glass, without minimizing the amount of light, entering your homes. It is a coating which helps to reduce heat transfer.

(j) Pyrolytic Coating:

Coating for excellent performance. It is a low e-coating which is applied at high temperatures and fired into the glass during the float glass manufacturing process.

(k) Self-cleaning Coating:

It keeps the surface of glass free from dirt by itself.

(l) Sandwichable Film or Smart Film Coating:

It alters the light transmission property when voltage, light or heat is applied. It is a coating that adjusts the light transmission.

(m) Water Repellent Coating:

It helps in making hydrophilic surface in glass.

(n) Sol-Gel Coating:

Preparation of thermally stable, transparent super-hydrophobic silica films.

Properties of Glass as Building Material

01. Glass Density

The density of building glass is around 2500 kg per cubic meter at 200 C temperature, which gives flat glass a mass of 2.500 kg per square meter per mm of thickness.

02. Glass Compressive Strength and Tensile Strength

The compressive strength of glass is 1000 N per Sq.mm (10197.2 Kg per Sq.cm) at 200 C temperature which is very high. It means that a load of 10 tonnes is required to break a 1 cm cube of glass.

The tensile strength of glass is significantly lower than that of compressive strength.

The resistance to tensile strength (deflection) is 40 N per Sq.mm (407.88 Kg per Sq.cm) at 200 C temperatures for annealed glass and 120 to 200 N per Sq.mm (1223.66 to 2039.43 Kg per Sq.cm) at 200 C temperature for toughened glass.

03. Glass Young’s Modulus or Modulus of Elasticity

The young’s modulus (Force per unit area) of any material is a measure of its stiffness. Larger the value of young’s modulus means stiffer the glass. The young’s modulus of glass is 70 GPa at 200 C temperature (The young’s modulus of concrete is 30 to 50 GPa at 200 C temperature).

04. Glass Poisson’s Ratio

Poisson’s Ratio is directly related to elongation and contraction of material when load is applied in one direction, and it is also known as lateral contraction co-efficient. The cross-section area of glass decreases as it is stretched. The Poisson’s ratio of glass is 0.22.

05. Glass Linear Expansion or Co-efficient of Thermal Expansion

Linear expansion is a stretch per unit length for a variation of 10 C temperature. The co-efficient of linear thermal expansion is 9 x 10-6 m/ 0 C.

End Note

According to the author of Architecture and Civil Engineering, ‘Jelena Savic et.al’, conceiving contemporary architecture without glass is difficult. It successfully contributes towards making a good appearance for the buildings. Also, it has the ability to reflect, bend, transmit, and absorb light all with great accuracy.

Therefore, the user can effectively choose correct application of glass according to their use after referring the above-mentioned points. Based on the important characteristics & properties of glass, it can be considered as the best future material for building construction.

Must Read:

Advantages & Disadvantages of Glass

FAQs: Characteristics & Properties of Glass as Building Material

01. What characteristics of glass make it a building material?

Transparency, hardness, weather resistance, chemical stability, and the ability to be moulded into any shape and size. These characteristics can also be modified for better performance.

02. Which glass is best for safety?

Toughened and laminated glass are the best from a safety point of view. Toughened glass shatters into small blunt pieces, while laminated glass holds together even after breaking.

03. How to improve the insulation of glass?

Double glazing, low-E coatings, and insulated glass units (IGUs) can improve the insulation of glass. These treatments provide excellent thermal protection and sound insulation.

04. Can glass provide fire resistance?

Yes. Modern glazing can provide up to 120 minutes of fire protection. The transparent glazing becomes opaque when subjected to temperatures above 120°C and resists fire.

05. What are the properties of glass as a building material?

– The density of building glass is around 2500 kg per cubic meter at 20°C.

– The compressive strength of glass is 1000 N per sq. mm at 20°C.

– The tensile strength of glass is 40 N per sq. mm at 20°C for annealed glass and 120 to 200 N per sq. mm at 20°C for toughened glass.

– The tensile strength of glass is 40 N per sq. mm at 20°C for annealed glass and 120 to 200 N per sq. mm at 20°C for toughened glass.

– The modulus of elasticity of glass is 70 GPa at 20°C.

– The Poisson’s ratio of glass is 0.22.

– The coefficient of linear thermal expansion is 9 × 10⁻⁶ m/°C.

– All these properties make glass an excellent choice of building material.

Author & Expert Review

Written By:  Nidhi Patel | Civil Engineer & Content Writer

Nidhi Patel | Civil Engineer & Content Writer

| Credentials: B.E. (Mahatma Gandhi Institute of Technical Education and Research Centre), Registered with Gujarat Technological University (GTU). Experience: Civil Engineer with 3+ years of content writing experience, currently writing blogs for Gharpedia, part of SDCPL. Expertise: Specializing in SEO-optimized blogs and long-form articles focused on home improvement, construction, interiors and architect topics. I create well-researched, reader-focused content that balances technical accuracy with clarity, making complex subjects easy to understand. Find her on: LinkedIn |

Verified By Expert:  Ravin Desai – Co Founder – Gharpedia | Co Founder – 1 MNT | Director – SDCPL

Ravin Desai – Co Founder – Gharpedia | Co Founder – 1 MNT | Director – SDCPL

This article has been reviewed for technical accuracy by Ravin Desai, Co-Founder of Gharpedia and Director at Sthapati Designers & Consultants Pvt. Ltd. With a B.Tech. in Civil Engineering from VNIT Nagpur and an M.S. in Civil Engineering from Clemson University, USA, and over a decade of international and Indian experience in the construction and design consultancy sector, he ensures all technical content aligns with industry standards and best practices.

Find him on: LinkedIn