Out of all Construction materials in the world, concrete is one of the most widely used. The two main components of concrete blocks are cement paste and inert materials. The cement paste consists of Portland cement, water, and some air. The inert materials are usually composed of fine aggregates such as sand and coarse aggregates such as gravel, crushed stone, or slag.

Autoclaved Aerated Concrete block is one of the major achievements of the 20th century in the field of construction. It is a revolutionary construction material offering a unique combination of high durability and strength, low weight and also contains superior ecological green features.

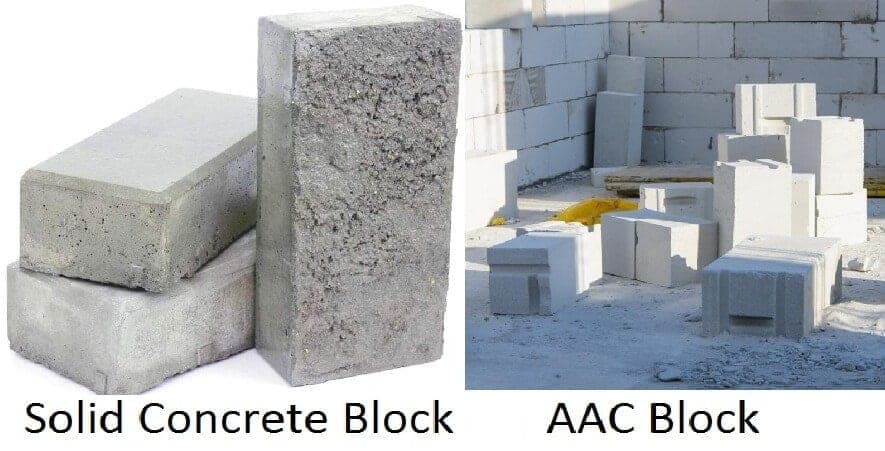

Solid Concrete Blocks and AAC Blocks both are important construction materials for constructing walls. Solid Concrete Blocks and AAC blocks are used in walls as per their properties, availability and cost. Hence, here we give you a brief comparison of concrete block & AAC Block to help you to make the right choice.

Solid Concrete Blocks Vs AAC Blocks

01. General

- Solid concrete blocks are one of the several precast concrete products used in construction. The term precast refers to the fact that the blocks are formed and hardened before they are brought to the job site.

- AAC Blocks are a lightweight building material cut into masonry blocks or formed of larger planks and panels.

- AAC Block is relatively uniform when compared to other wall unit materials and does not contain coarse aggregate phase.

02. Raw Material

- Solid concrete blocks are made of a mixture of Portland cement, water, sand and gravel.

- It is made by the mixture of fly ash, cement, lime, gypsum and an aeration agent.

- The Fly ash used in AAC Blocks production is eco-friendly & Cement is used in very little Quantity.

- The Problem of fly ash disposal is solved by the use of fly-ash in AAC Block, which was a major problem till day.

03. Uses

- Solid concrete blocks are used for load-bearing as well as non-load bearing walls.

- It is also used for constructing retaining walls, garden walls, chimney and fireplaces.

- It is also used as a lintel.

- AAC Blocks can be used to build internal as well as external walls.

- It can also be used for both load bearing and non load bearing walls.

04. Advantages

- The design of solid concrete blocks is flexible and easy to construct.

- Solid concrete blocks are ideal for foundation and basement wall.

- Solid concrete blocks are unaffected by termites.

- Solid concrete blocks provide insulation against cold and hot weather.

- The solid concrete blocks wall is long lasting, durable and requires less maintenance.

- The Solid concrete blocks are highly resistant to extreme weather conditions such as storms, floods and high winds.

- The Solid concrete blocks are highly resistant to cracking and crumbling in extreme temperatures, unlike poured concrete.

- The Solid concrete blocks are virtually soundproof.

- Earthquake forces are proportional to the weight of the building and hence it ultimately reduces the dead load on buildings, and hence less steel in case of RCC structures.

- Saves steel and concrete due to the reduction in dead weight.

- Increase in floor area due to the reduction in the size of columns and thickness of the wall.

- AAC blocks are very easy to handle and ordinary tools are used for cutting.

- AAC blocks are available in large sizes and hence less no of joints. This ultimately results in faster construction on site and less consumption of cement.

- AAC blocks are made from inorganic material which helps to avoid termites, damages or losses

- Easy to transport on upper floors

- Time-saving in construction

- AAC blocks are having a very low thermal conductivity which keeps interior remain cool in summer and warm in winter

- AAC blocks reduce interior temperature variation maintaining pleasant and healthy temperature for habitant

- AAC blocks reduce the energy cost of air-conditioning to a great extent due to its thermal property

- AAC blocks are appropriate for fire rating application for desired safety.

- There is minimal wastage in case of AAC blocks

- It is environment-friendly and also saves water. Hence it is popularly used as a green product

- Though the production cost of AAC Blocks is high but on the whole the project cost decrease.

05. Disadvantages

- The cost of building with solid concrete blocks can be higher than traditional framed construction.

- Weight of solid concrete block is more than AAC Block

- Due to the heavy weight of concrete structural cost is high.

- It is difficult to make arrangements for concealed work for wiring, plumbing & conduit.

- The production cost per unit for AAC Block is higher.

- Plaster sometimes does not stick properly because of its smooth surface.

- Needs care during it production itself, so that surface is not very smooth.

06. Identification on Site

- Colour of Solid concrete block is light Grey

- Colour of AAC Block is Grey

Also Read: Difference between Framed & Load Bearing Structure

07. Properties

(a) Size Available in Market

- 400-600X100-200X50-300

- 400-600×100-200×100-300mm

- However it defers from manufacturer to manufacturer.

(b) Variation in Size

- The variation in the length of the units shall not be more than 5 (+/-) mm and variation in height and width of units not more than 3 (+/-) mm.

- 1.5mm(+/-)

- The AAC Blocks are accurate in size because it is produced by wire cut technology and is a factory product.

(c) Dry Density

- 2500 kg/m3

- 451-550

- 551-650

- 651-750

- 751-850

- 851-1000 Kg/m3

- Depending upon fly ash aeration

(e) Weight

- 17 – 26 Kg

It will depend on Density & sizes of block. Hence difficult to handle.

- 3 – 4 kg

It will depend on Density & sizes of Block and easy to handle.

(e) Compressive Strength

- 40-50 N/mm2

- Strength is defined as the capacity to resist force or pressure.

- 30-35 Kg/cm2

- But to fulfil wall in RCC structure you do not need more strength.

(f) Water Absorption

- Water absorption of blocks should not be more than 10 % of its weight.

- Water Absorption of this block should not be 10 % its volume.

(g) Fire Resistance

- 100 mm thick solid concrete block wall can resist fire for up to 4 hour.

- 100 mm thick wall can resist fire for up to 4 hour.

(h) Thermal Conductivity

- 0.7- 1.28 W/mk

- The amount of heat transfer from a specific material which is called thermal conductivity.

- Thermal conductivity of block is high and hence heat transfer from block is more than AAC block.

- 0.21 – 0.42 W/mk

- Thermal conductivity of block is lower and hence less heat transfer from block.

(i) Sound Insulation/Noise Transmission

- Sound insulation is defined as the capacity to reduce sound transmission by building elements.

- Sound transmission also depends upon the thickness of the wall.

- 51 db sounds gets reduced by 150 mm wall.

- The AAC block has good sound transmission property due to the presence of air voids.

- 40-45 db sound gets reduced for 200 mm thick

(j) Termite Resistance

- Solid concrete block does not allow the spread of termites and pests hence increase the life of wall.

- AAC blocks are insect resistant, inorganic and solid wall construction material.

- AAC block also does not allow the spread of termites and pests hence increase the life. of wall.

08. Efficiency

(a) Labour Output

- Solid Concrete Blocks are large in size and shape. This ensures rapid construction hence more walls are laid per man-hour as compared to brick but not as compared to AAC block.

- Rapid Construction will be done due to the bigger size and less weight of AAC Blocks.

(b) Carpet Area

- More carpet area is available due to less thickness of the block.

- More carpet area is available due to less thickness of the block.

(c) Applicability

- Solid concrete blocks are used for both load bearing as well as Non-Load Bearing wall.

- AAC Blocks are recommended for high-rise buildings because it substantially reduces total dead load of building

(d) Mortar Consumption

- Requires less joints and hence considerable saving in mortar-as compared to normal masonry constructions.

- Requires less mortar due to flat and even surface & less number of joints.

(e) Speed of Construction

- Speedy construction of wall due to bigger block size and less number of joint.

- Speedy construction of wall due to the bigger block size, light in weight and less number of joint.

(f) Water Usage During Manufacturing

- Requires more water for curing and hence higher amount of electricity bill and labour cost.

- Block is basically cured by steam and block masonry also requires less curing hence less use of water and saving in electricity bill.

(g) Breakage & Utilization

- Negligible breakage happens due to its hard surface.

- Negligible breakage almost 100 % utilization is possible.

(h) Storage

- The solid concrete blocks shall be stored in such a way as to avoid any contact with moisture on the site. They shall be stockpiled on planks or other supports free from contact with the ground and covered to protect against wetting.

- Readily available at any time & any season in a short notice hence no storage required.

(i) Efflorescence

- Efflorescence occurs due to presence of salt in water and sand.

- Efflorescence occurs through mortar and water.

09. Cost

(a) Structural Cost

- No such saving is possible

- Steel saving up to 15% & Concrete saving up to 7% AAC Blocks reduces the load on foundation due to its low self-weight and saves consumption of steel. Hence reduces the Structural Cost.

10. Environment Impact

(a) Green Product

- It is not a green product.

- It basically solves the headache of disposal of fly ash from the power station and hence environment-friendly.

- AAC Blocks are made from the non toxic material which does not harm the environment. Using it reduces the industrial waste and it also decreases greenhouse gas emissions.

- During the manufacturing process, Waste of the AAC Block is recycled and used again. This waste is made from the cutting process.

- Hence AAC Blocks are Green product.

(b) Earthquake Resistance

- The solid concrete Blocks resists average earthquake forces because the density of Concrete Block is higher than AAC Block.

- Earthquake forces are proportional to the weight of the building. AAC Blocks reduce the weight of building so it increases the safety against earthquake.

Special Comment

The solid concrete blocks are used as an alternative of clay bricks but concrete blocks are heavy in weight hence buildings becomes heavy. The cost of concrete block masonry is also high hence AAC blocks are used in the construction of the wall. Using AAC block is very advantageous because it conserves the environment, saves energy and provides safety to life.

Also Read:

Clay Brick Vs AAC Block How to Make the Right Choice

10 Qualities of a Good Clay Brick