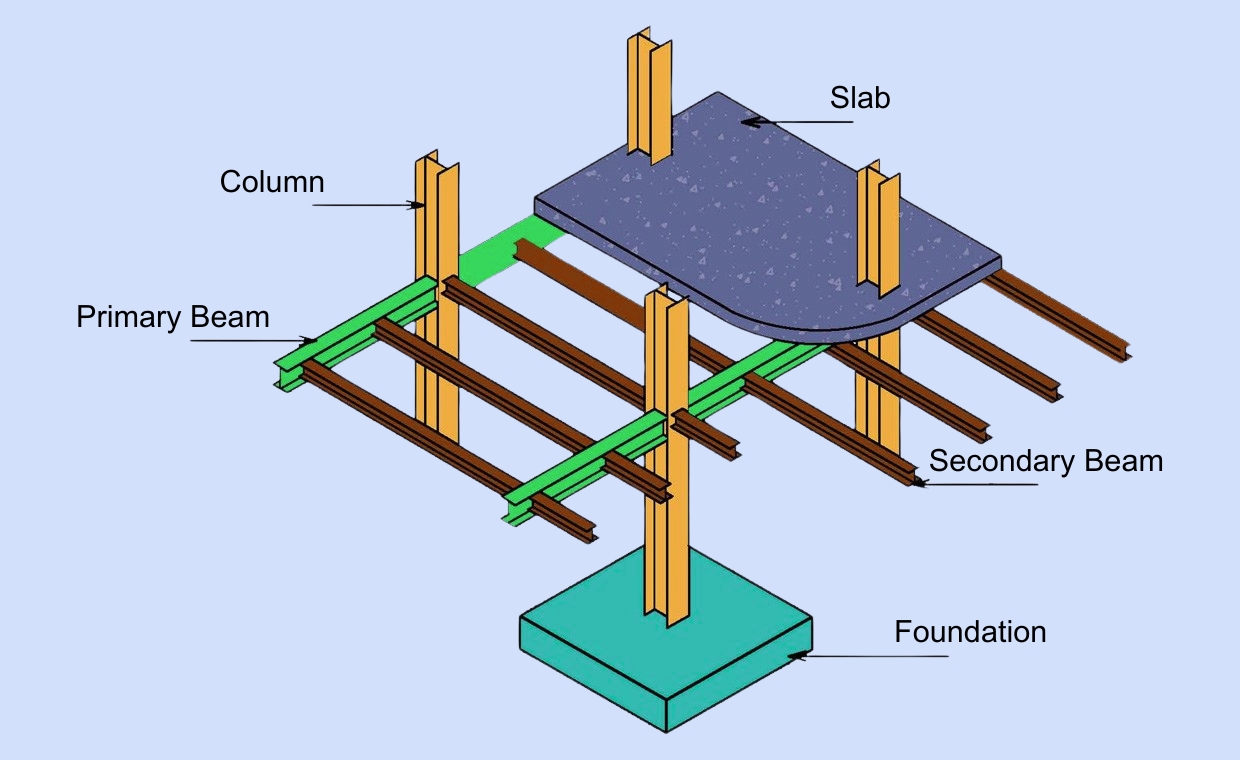

A column is generally a vertical member which transfers loads to the ground through footings. The columns help the house to withstand the different loads like buildings own weight, occupant’s weight, the weight of furniture and goods of the house, etc. Columns are very important members of the house, hence special precautions must be taken during column casting. Most of the buildings collapse due to the failure of the column. Please note it would be almost impossible to handle the building if the column fails. To prevent this, proper checking should be carried out while concreting the reinforced concrete column.

To check the column, you need knowledge of engineering practices. Following are the four stages of checking which need to be carried out before column casting.

01. Checking of column Layout and centre

02. Checking of column reinforcement

03. Checking of column shuttering

04. Checking of column concreting.

Procedure to Check the Column

01. Checking of column Layout and centre.

Nowadays homeowners want to build the house which is properly designed by the architecture/consultant. The well-reputed architects always provide the separate drawing of column layout with their centre. This drawing shows the centre line or exact positions of each column at the site according to the reference dimensions. Hence, study the drawing of column layout carefully and check, whether the location of the column starter is according to the reference dimension shown in drawing or not?

Column Starter Construction:

Starters are needed to cast the column in proper alignment. Column starter marking is the process of casting the first 50 to 100 mm height of column for the alignment of rest of the column. To construct the column starter, shutters are made to the size of the column and the height of shutter should be normally 75 to 100 mm. The shutters are fixed at the bottom of the column according to the centre line. Check the shuttering and reinforcements of the starter for a verticality. After the curing period is over, remove the formwork of the starter. The shuttering of the remaining column should be fixed by overlapping the shutter on casted starter.

In case of footing and slab, the shuttering should be fixed and checked first before placing the reinforcement. This is necessary as certain formwork defect can’t be corrected or are difficult to correct after reinforcement is placed in position. But in the case of the column, the reinforcements of the column should be fixed and checked first, then the shutter should be fixed it is however observed that though ideal, this practice is not followed on most of the sites.

Also Read:

Things to Check Before Concreting Beams & Slabs

Things to Check Before Concreting Footings

02. Checking of column reinforcement steel

Following checks for column reinforcement should be carried out before column casting.

- The reinforcement steel should be free of any loose scale, rust, mud, or oil.

- Main reinforcement and ring of column should be cut as per required length.

- The stirrups should be carefully cut in length as extra length will result in large size of stirrups/ rings resulting in less cover to concrete, which is never advisable.

- When a column reinforcement is rested on the reinforcement of footing or mat, special confining reinforcement (main vertical bars) should be extended at least 300 mm or as per drawing.

- In a reinforced column, the area of longitudinal reinforcement shall not less than 0.8 percent or more than 6 percent of the gross cross-sectional area of the column as per IS code.

- A minimum number of 4 bars shall be provided in a square or rectangular column and six bars in circular column with helical reinforcement.

- The bars shall notbe less than 12 mm in diameter and spacing of the bars along the periphery of the column shall not exceed 300 mm.

- Longitudinal bars shall not bespaced more than 75 mm on either side, transverse reinforcement need only to go round corner and alternate bars for the purpose of providing effective support.

- The diameter of the rings or ties shall be not less than one- fourth of the diameter of the largest longitudinal bar and in no case less than 6 mm. However, we recommended 8 mm diameter bars,

- Main reinforcing bars and stirrups should be tied tightly to each other by using binding wire of proper gauge, preferably 16 gauge.

- Check the size of stirrups before tying. Hook angle in link or stirrups should be 135°.This is very important from seismic considerations. This alone will increase your buildings capacity to withstand earthquake force. Hence very important.

- Lapping should be provided in the central half of the member length and lap length should be 45D (D is the diameter of the bar). In central half of member, the lapping of bar should be alternate if possible.

- Lapping should be in joggle if diameter of bar is more than 12 mm.

- Spacing near support should be less than middle portion of column.

- Before placing the concrete, Check the reinforcement details with bar bending schedule and get an approval from structural consultant.

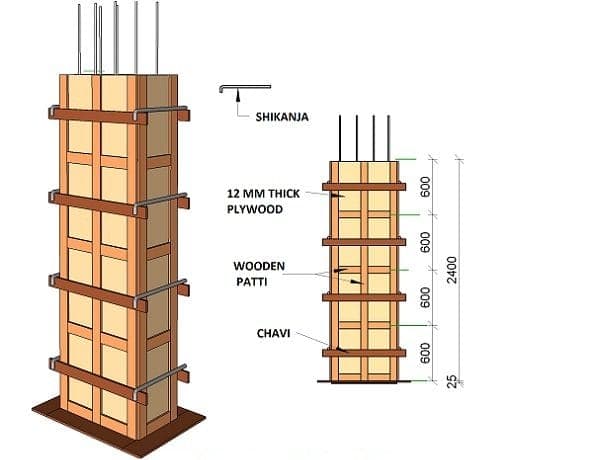

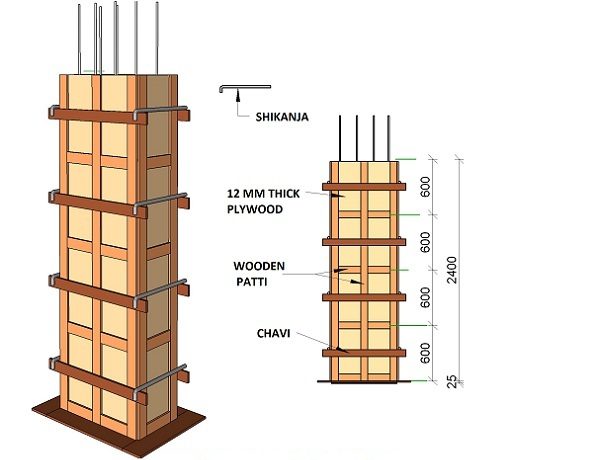

03. Checking of Column Shuttering

Following checks of column shuttering should be carried out before column casting.

- Check the size of shuttering for column and it should be as per drawing.

- Check center lines of columns with respect to adjacent columns or as specified in drawing.

- The column shuttering should be strong enough to take the pressure of fresh concrete and remain in position during concreting, particularly when vibrator is applied.

- To hold the concrete shuttering firmly in place with proper alignment, concrete starter called “kicker” should be cast before fixing the shuttering and of same concrete mix.

- The starter should be hard enough to fix shuttering around it.

- Column box or shuttering for column should be made of plywood sheets or steel sheets fabricated with adequate battens and stiffeners.

- Apply water-based shuttering oil on the shutter. It helps to get the good finished surface of the concrete. The shuttering oil enables the easy removal of column formwork after the concrete hardens. It also increases the numbers of shutter repetition, i.e. life of shuttering.

Do not apply oil or grease in place of shuttering oil. It will leave a dark mark on the surface of the concrete. It very difficult to remove oil or grease from the construction joint and in future, the joint becomes weak which may result into the cracks in concrete.

Also Read:

Removal of Formwork: Know the Correct Time and The Precautions

Big Mistakes that must be Avoided in Formwork while Concreting

- Shuttering should be properly aligned to its verticality and diagonal. It should be checked to ensure the accuracy of dimensions.The column should be acceptably accurate in shape and position with good alignment to other adjacent columns, walls etc. It should be as per predetermined grid specified in drawing.

- Plumb the formwork both ways and support it by using adjustable steel props or wooden prop.Ensure the steel props are safely secured to the column formwork and the floor, and that adjustment for pushing and pulling is operational. It is necessary to check the plumb again after providing the supports. Hence check the plumb of column shuttering by using plumb bob.

- The propping angle should be 45 °to the floor.

- It should be thoroughly supported to props or ties before pouring the concrete so that it does not move horizontally or vertically during concreting.

- Sufficient quantity of clamps (shikanjas) should be fixed to prevent bulging of the column during concreting. It should be fixed at a 0.60m (2’0″) interval. Sometimes contractors use binding wire in place of shikanjas, but in large size of columns, they are not effective, and hence not recommended.

- Check the size of column as per drawing.

- The gap between the joint of shutters should be sealed to prevent any leakage of cement slurry.

- Appropriate space to be provided between the inner face of the shutter and reinforcement by fixing cover block as provided in drawing. This is very important to save your column from failure of corrosion of bars.

- Make sure that cover block used for casting of column have the same grade as of concrete. They are not broken and properly positioned and should not get disturbed during concreting operations.

Minimum 40 mm cover should be provided in column. It also depends on fire resistance needed of a building.

- Permissible concreting level should be marked by considering beam depth.

- A hole is usually provided at the bottom of formwork to remove debris, etc., before placing the concrete. This clean out hole is covered before starting the concreting work.

- In case of tall forms, it is desirable to provide windows at appropriate level on at least one face to facilitate inspection, concrete placement and vibration.

04. Checking of Column Concreting

The checking of concreting is as important as the checking of the shuttering and reinforcement of column. We have already discussed the do’s and don’ts of concreting. Read the tips for concreting.

Columns are basically vertical members which span from substructure to superstructure and transfer the load from top of the structure to the ground. The poor workmanship while the shuttering work, reinforcement fixing work or concreting work ultimately affect the strength of the column which will cause enormous repairing problems in your house, thereby reducing the life of your structure.

Must Read:

What are Floating Columns? Are they Advisable?

5 Right Steps for Repairing of Concrete