The building sector consumes one-third of the world’s global energy. The major reason being, the residential and commercial buildings all over the world makes the utilisation of artificial light. Thus, in order to reduce the artificial light, it is necessary to increase the amount of natural light entering into the building. In addition to that, if we utilize the materials that have excellent thermal insulation properties, then that would be even more affective in having energy-efficient buildings which will save energy as well.

Wood is an excellent insulator. Because of its better insulation property, wood has been used as a building material for centuries. The excellent material properties of wood originate from its hierarchical structure and also from its distinct fibre directionality. Wood is made up of fibres that are oriented in the direction of growth of the tree. These fibres are made of three main components; namely – cellulose, hemicellulose and lignin.

Wood, as we all know is not transparent in nature. This is mainly due to the presence of lignin in the wood which absorbs light. Lignin also imparts brownish colour to the wood which we are all familiar with.

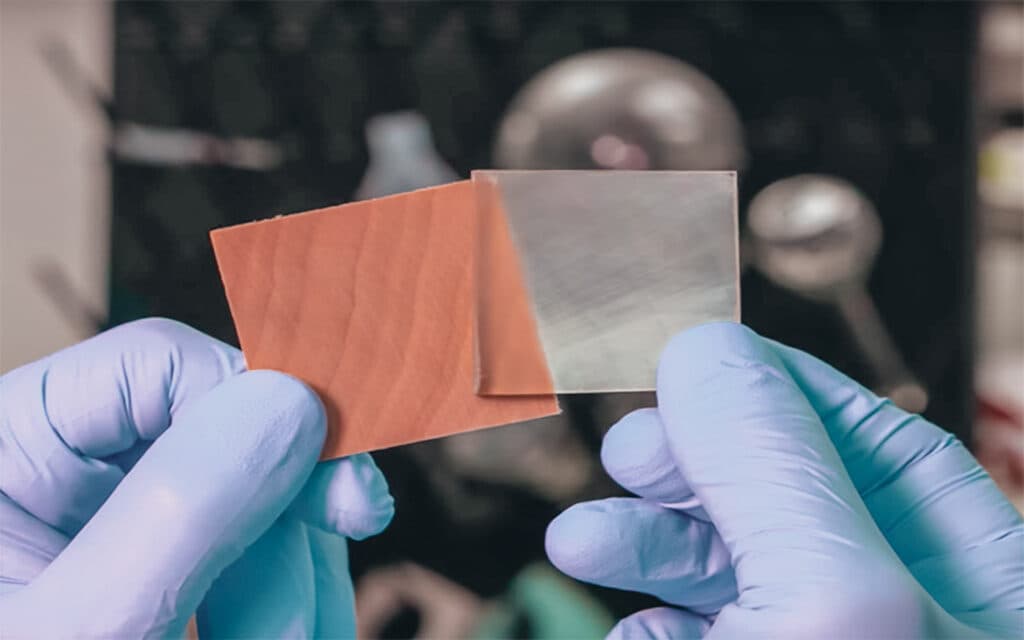

If the lignin is carefully removed from the wood; you obtain a material which is without lignin. The material obtained is not completely transparent and it is white in colour. This is because of excessive scattering that occurs inside the wood. Now, if you fill up all the pores of the wood with a material that matches the refractive index of the wood, then you can obtain transparency.

Wood is an amazing building material. But at the same time there are couple of drawbacks associated with it. Wood rots, gets eaten by termites, and even blocks light. Hence, engineers at the University of Maryland figured out a way to make wood that was clear, more durable and even stronger. They basically bleached and boiled the wood to remove the brown coloured chemical called Lignin.

A noteworthy characteristic of transparent wood is, it can withstand stress ten times more and strain four times more in comparison to the normal conventional wood.

History of Transparent Wood

Transparent wood for the first time was created in the year 1992 by a German researcher Siegfried Fink. But it was not until between 2015 and 2016 when the two professors, Professor Lars Berglund from Swedish KTH University and Professor Liang Bing Hu from the University of Maryland, developed a method to eliminate colour, some of the chemicals from small wood samples and added polymers to make it transparent.

Functions of Transparent Wood

According to ‘Yuanyuan Li’ et. al (Published in: Optically Transparent Wood: Recent Progress, Opportunities, and Challenges), Transparent wood is multi-functional in nature. As mentioned earlier, when the lignin is removed from the wood, it becomes white in colour. Another feature which is quite interesting is, when you remove the lignin from wood, you add extra porosity to it.

Mentioned below are some of the properties of Transparent Wood:

01. Heat storage – Property of Transparent Wood

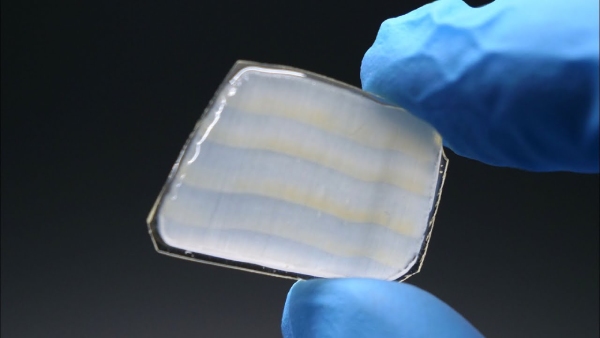

Transparent wood can be used as an encapsulating material for preventing the leakage of the phase change material. Wood has an ideal structure since it has Nano porosity. Hence, it works really well to retain the phase change material from leaking out. Here, polyethene glycol is used as a phase change material. It is infiltrated into the wood without lignin. Then, acrylic such as polymethyl methacrylate is added in order to increase the transparency and hydrophobicity of the final material. The final product thus obtained is Transparent Wood for heat storage. This transparent wood can effectively absorb heat, store it and release it whenever needed. The wood generally absorbs heat when the temperature is more than 30 degrees Celsius, and will release the heat once it starts cooling down.

02. Transparency – Property of Transparent Wood

Another interesting feature of transparent wood is that, the intensity of its transparency changes a bit with the change in the temperature. This generally happens when phase changing occurs. For instance, if it is hot outside, the material will absorb the heat and become transparent. And once the night sets, the temperature decreases, it starts releasing the heat and turns opaque.

Mechanical Properties of Transparent Wood

The mechanical properties of transparent wood are intentionally enhanced to a greater level in comparison to the neat polymers such as Polymethyl methacrylate (PMMA). Properties of transparent wood are basically determined by the combined contribution of both wood template and the infiltrated polymer phase. They are also affected by the interfacial bond properties between the wood template and the infiltrated polymer.

The mechanical properties of wood are majorly determined by the cellulose content already present in it, as well as by the intrinsic geometric orientation of the wood fibre cell structure. Additionally, the properties of wood also depend upon the relative density and morphological details of the wood structure. Hence, the properties of transparent wood strongly depend on the properties of basic wood.

Some of the properties are mentioned below:

01. The tensile strength of transparent wood increases with an increase in wood/cellulose volume fraction.

02. With the same PMMA (Polymethyl methacrylate) polymer, the mechanical properties of transparent wood will change when the wood of different species is used.

03. Transparent wood does not shatter in an unfavourable way.

04. Transparent wood exhibits a typical combination of high optical transmittance and haze.

05. It has low thermal conductivity as well as low density.

06. Transparent wood also exhibits anisotropic optical and mechanical performance.

07. It has outstanding toughness.

08. The thinner the sample, the higher is its optical transmittance. This is because the transparency is dependent on the volume fraction of cellulose.

Apart from transparent wood, we have also written an article on oak wood. Click below to know about it.

The Pros of Transparent Wood

01. One of the major advantages of transparent wood over the typical glass in terms of its structural applications is its ductility and resistance to fracture which is higher compared to glass. The transparent wood is almost transparent as a glass but it has much higher strength than any glass.

02. Transparent wood is a better biodegradable material in comparison to plastic.

03. Transparent wood could be used to create super strong and energy-efficient windows.

04. According to ‘D. Katunsky’ et. al. (Published in: Structural Elements with Transparent Wood in Architecture), transparent wood sets the path for greener architecture and better electronics.

The Cons of Transparent Wood

The only drawback that can be pointed out with Transparent Wood is; the epoxy isn’t environmental friendly. Currently, it is only possible to make it in the labs. But the engineers are confident that very soon they will be able to swap the epoxy with recyclable plastic and scale the process. This means that the buildings partly made with transparent wood shall be dominant in the future.

Applications of Transparent Wood

Since the material combines structural performance with functional properties such as high transmittance and haze, this rare combination is emphasized for better applications. Construction of a transparent building structure can be put into one demonstration, where the light transmittance can be designed in such a way that the artificial light can be partially replaced by sunlight. In order to ensure more uniform and soft nature of the transmitted light, high haze can be used so that the indoor privacy is also safeguarded. There is a very interesting fact about transparent wood, that though it is made out of natural wood, it is stronger than its origin. Similarly, it is also stronger compared to the polymer which is utilized for its creation. For this reason, the structural elements made of transparent wood are not only elegance in appearance but they are also a very smart solution.

Some of the applications of transparent wood are mentioned below:

01. Transparent wood roofs can be designed to certain buildings for providing uniform and comfortable illumination as compared to conventional glass.

02. In addition, Panels can be built from transparent wood which exhibits lower thermal conductivity, better impact strength, and lower density as compared to glass.

03. Functionalised transparent wood provides even better opportunities for smart buildings. By inclusion of quantum dots, transparent wood attains diffused luminescence properties. This can be used in planar light sources, luminescent building elements, or designed furniture.

04. In order to provide electromagnetic interference shielding to the transparent wood, magnetic nano particles have been incorporated into it.

05. Another important application of transparent wood is; it is used as a structural material for some of the photovoltaic devices such as electrochromic devices and solar cells. Because of the high haze, transparent wood can be designed as a light-diffusing layer. Furthermore, high haze means large scattering angles, which increase the length of the light path inside solar cells, so that efficiency is improved.

06. The devices exhibit a vibrant magenta-to-clear colour change with a high colouration efficiency and low driving voltage. This entire concept will contribute to smart windows, which in turn saves energy.

07. Transparent wood can be used on façades in cases where there is requirement for sunlight to illuminate the interior, but privacy is equally important. It is because of the high values of optical haze in transparent wood, which lets the light in, but clouds the view; it can be used for those peculiar cases.

The Manufacturing Process of Transparent Wood

To make transparent wood, both absorption and scattering needs to be eliminated. The quantity of light absorption in transparent wood is strongly related to its chemical composition. In appearance, wood is brownish in colour, which is due to the presence of light-absorbing components such as lignin, chlorophyll and tannins. Lignin in particular, amongst the above-mentioned components, is responsible for approximately 80–95% of light absorption in wood. This light absorption can be drastically reduced by chemical treatment of the wood either by removing “all” the lignin or deactivating the chromophores within the lignin.

Transparent wood is produced by treating and compressing the wooden strips. The basic way to manufacture transparent wood is to take a piece of ordinary wood or wooden block and place it in a bath of boiled water, Sodium hydroxide and Sodium sulphite. The next step is to just let it remain soaked there for about 12 hours. This process strips away all the opaque stuff and leaves behind floppy transparent structural cellulose.

Once you get rid of all the cellulose, sink the wooden piece into a bath of hydrogen peroxide which will further bleach it a little more. Both these steps are apparently the standard method used to create paper thereby making it look smooth and white. This process leaves behind bone-white wood fibres. The wood looks crunchy after the process since the lignin is “nature’s glue”.

The final step is to transfer all the cellulose and bubble epoxy in a vacuum chamber. Wood is basically put under a vacuum and is later smothered with clear epoxy. The tubes that are made of wood fibres soak up the epoxy resin. When it dries up, a see-through or transparent wood is obtained. Wood grains are even visible on it, but it is incredibly tough.

The time duration taken for a thin piece of wood to completely undergo the process is about 10 minutes whereas it takes almost 24 hours for a wooden log.

We have also explained the manufacturing process of wood veneer. Please do have a look,

Conclusion Transparent wood is an interesting topic in the emerging field of wood nanotechnology – both in the academics and in the industrial context. Noticeable progress has been made which includes manufacturing of transparent wood with improved mechanical properties, producing larger and thicker transparent wood structures, along with the realization of transparent wood fictionalization. In-depth study is required to understand the light–wood interaction to tune the optical and mechanical properties, improve the “green” aspect and to explore advanced transparent wood applications.

Transparent wood is a newly invented material. Currently it is a topic of research and undergoing through various experiments, but it certainly holds a great potential for becoming an important building material. Its translucency along with its outstanding mechanical properties is making it an interesting choice for using in façades and for that fact, it is gradually paving its way towards being listed as a structural material in the field of construction.

Must Read:

Beginners Guide to Teak Wood for Furniture Making!

Pinewood: A Popular Softwood Used for Home Furniture!

Image Courtesy: Image 1, Image 2, Image 3, Image 4 – semanticscholar, Image 5

Author Bio

Arfa Falak – My name is Arfa Falak and I have my graduation in BE (civil). I live in Bangalore. I am an aspiring design Engineer.