Doors and windows are not only the essential components of a building structure but also represent vulnerable points in its external envelope. Creating an opening to a building requires careful engineering as you need to make sure that structural and thermal stability is maintained while doing so. That’s where a lintel comes into play.

What is a Lintel?

Lintels are flexural members (beams) and parts of the structural system. They are horizontal (members) required to support the wall above the openings in a wall, such as a door, window, or a louver.

Types of Lintels Based on Materials of Construction:

(a) Wooden Lintels

(b) Stone Lintels

(c) Brick Lintels

(d) Reinforced Brick Lintels

(e) Concrete Lintels

01. Plain Concrete Lintels

02. Reinforced Concrete Lintels

01(a) Precast Lintels

02(b) Cast in Situ Lintels

(f) Steel Lintels

- Standard Cavity Steel Lintels

- Wide Inner Leaf Steel Lintels

- Wide Outer Leaf Steel Lintels

- Short Outer Leaf Steel Lintels

(g) Specialist Lintels – Catnic

(h) Cavity Lintels

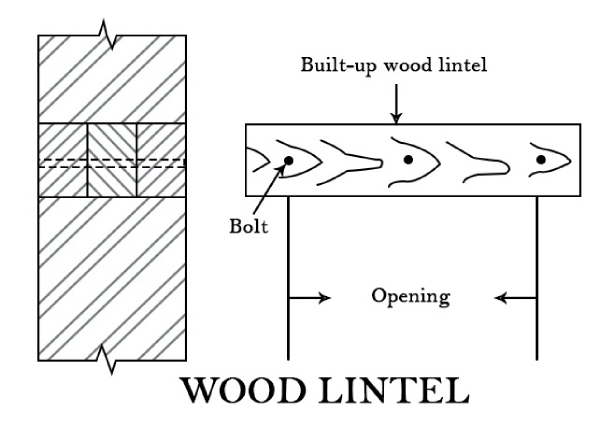

(a) Wooden Lintels

These are the oldest type of lintels but are used even today. Wooden lintels are commonly used in hilly areas where timber is cheaply available in abundance. In plains, the wooden lintels are rarely used on account of their high cost, susceptibility to catching fire, and susceptible to decay because of rot or termites.

Wooden lintels may either consist of a single piece of timber (for small spans) or built-up sections of two or more pieces held together by bolts at suitable intervals. Refer to the figure above. These built-up lintels are generally used for larger spans. The wooden lintels are placed, with the proper bearing at the ends, to span across the openings. Later, the masonry is constructed over it. Wooden lintels are comparatively weak; therefore, relieving or discharging arches of brick or stone are provided over them. The space between the lintel and the arch is filled with a brick or stone core.

The following points on wooden lintels should be given due consideration:

- Wooden lintels should be made of sound and hard timber, like teak, rosewood, or sal. Otherwise, they are likely to be destroyed by fire and decay or may bend under heavy load.

- The amount of bearing of lintel ends should be adequate (usually 15 to 20 cm). This horizontal structure should rest on mortar to offer firm and uniform support to the structure.

- The depth should be 1/12th of the span or 15cm, whichever is greater. Its width is kept equal to the thickness of the wall.

b) Stone Lintels

These are recommended only in places where the stone is available in abundance and the structure is made of stone masonry. The stone lintels may also be used in buildings which consist of stone facing. Stone lintels are made of slabs of stones of sufficient length without flaws either in single piece or combination of more pieces. The thickness of the stone lintel should be 80 cm, or 4 cm for every 30 cm of the span, whichever is more.

The use of stone lintels, in general, is not recommended because of the following reasons:

- Stone, being of poor tensile strength, cannot withstand the transverse stresses. Hence stone lintels should never be used for an opening exceeding 1-meter span unless provided with relieving arches above, otherwise, they would require abnormally deep lintel.

- It is difficult to obtain the slabs of stones of sufficient length and depth, free from defects or flaws. Moreover, the stone lintels prove to be costly as they require a good deal for quarrying, transportation to a worksite, dressing, and special handling on the site due to its weight.

(c) Brick Lintels

These are used to span small openings (less than one meter) with light loading. They generally consist of bricks which are normally laid on end and occasionally on the edge.

The brick lintel is constructed over temporary wood support (i.e. acting as centring) known as turning piece. Bricks with frogs are more suitable for construction of lintels as they form juggles when bounded and hence possess more shear resistance at the end joints (greater strength). The structure formed by using frog bricks is termed as ‘joggled brick lintel’.

The following points should be given due consideration:

- Bricks should be hard, well-burnt, free from defects such as lumps, cracks, and flaws, and with sharp and square edges.

- The depth of the brick lintels, which varies with the size of opening and appearance of brickwork, should be a multiple of brick courses. That’s usually 10 cm, 20 cm, and so on.

- For bonding frog bricks, the proportion of cement mortar mix of 1:3 should be used.

- Door frames and window frames should be fixed with a setback of 2.5 cm from the external face of the wall.

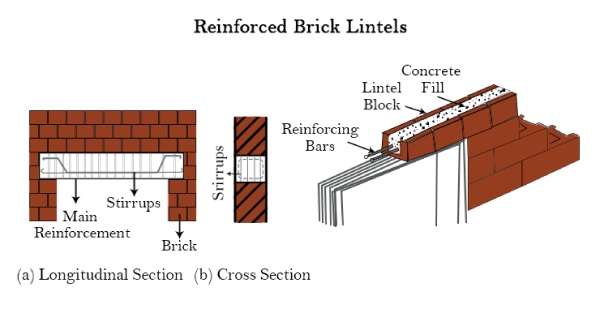

(d) Reinforced Brick Lintels

When brick lintels are required to be used over large spans, they are reinforced with steel bars. These lintels are constructed on the same principles as RCC lintels, the only difference being good quality bricks are used instead of concrete. The bricks are so arranged in parallel rows (either on edge or flat) that a 2 cm to 4 cm wide space is left lengthwise for inserting the reinforcement i.e., steel bars or rods. These spaces with reinforcement are then filled or embedded with rich cement mortar or cement concrete. But they are not recommended in an area with high intensities of rain or humidity. This is because the bars may corrode over a period of time, thus weakening the lintel.

(e) Concrete Lintels

Nowadays, the most commonly used types of lintels are concrete lintels which are made of cement concrete. They are of two types.

01. Plain Concrete Lintel

02. Reinforced Concrete Lintel

01. Plain Concrete Lintel

- These are prepared with plain concrete beams. They are devoid of steel bars; hence, they are not useful for heavy loads.

- They are made for only a span of up to one meter.

- Concrete is strong in compression but weak in tension. Hence, these lintels are not used for a longer span.

02. Reinforced Concrete Lintels

In modern times, reinforced concrete lintels are extensively used. RCC has replaced all other construction materials due to the following reasons or advantages –

- RCC lintels are fire-proof, durable, strong, economical, and easy to construct.

- The relieving arches are eliminated if RCC lintels are used.

- These lintels can be used for varying spans as well as loading conditions.

- The speed of construction is increased if precast RCC lintels are used.

RCC lintels are constructed usually with a concrete mix having proportions 1:2:4 (1 cement: 2 sand: 4 broken stone aggregate, by volume), reinforced with mild steel bars.

The plain concrete is unsuitable for lintels as it is comparatively weak in tension. Hence, lintels are commonly strengthened by using mild steel bars or some other form of reinforcement. The amount of reinforcement depends upon factors, namely the width of the opening, a span of the lintel, and the total load to be carried by the lintel.

Nowadays, most lintels are provided with weather shades or ‘chhajja’. When you do this, you need to exercise a lot of precautions. Read here to understand the precautions you should be taking.

Types RCC Lintels

RCC lintels may be either pre-cast or cast in-situ:

01(a) Pre-Cast RCC Lintels

Pre-cast RCC lintels are preferred for small spans up to 2 meters or so. They are cast in wooden moulds and cured well in advance. Pre-cast lintels prove to be economical as the same mould can be used to prepare a number of lintels. Moreover, the use of pre-cast RCC lintels assures speedy construction as it doesn’t need extra time for curing or removing of props. However, while laying a pre-cast lintel, special care should be exercised to see that the marked face is on the top or upper side.

All pre-cast lintels are marked with tar or paint at the top after pouring concrete in the mould so as to distinguish it from the bottom. This is essential because if the faces are reversed in position or the reinforcement is reversed, there will be a structural failure, endangering the structure.

According to ‘M. M. Goyal’, it is common practice to precast lintels for most normal door and window openings, the advantage being that immediately the lintel is placed in position over the opening, brickwork can be raised over it whereas the cast-in-situ lintel must be allowed to harden before brickwork can be raised over it. Precast lintels must be clearly marked with letter ‘T’ to indicate the top of the lintel so they are correctly bedded in position with the steel reinforcement at the bottom of the lintel.

02(b) Cast-in-Situ Concrete Lintels

For larger spans, the lintels should be cast in-situ. For cast-in-situ RCC lintels, erection of centring, placing of reinforcement, and concreting is done as usual. The ends of the bars are hooked to increase the grip or bond between them and the concrete. For lintels, the depth and reinforcement requirements may be compared as below:

(i) Depth of Lintel

- For ordinary loads, adopt 15 cm depth for spans up to 1.2 m. Add another 2.5 cm for every additional 40 cm spans.

(ii) Reinforcement in Lintels

The number of main bars depends upon the load to be carried from the wall above and the span of opening. As a rule, for the thickness of wall 10 cm (half-brick), adopt 2 bars and for every additional 10 cm thickness, one main bar should be added. The diameter of the bar varies with the span and is adopted as follows, as a general rule (Alternate central bars are bent-up)

- 6 mm Φ for spans up to 1 meter.

- 8 mm Φ for spans 1 to 1.5 meters.

- 10 mm Φ for spans 1.5 to 2 meters.

- 12 mm Φ for spans 2.0 to 3.0 meters.

According to ‘IS 9893 (1981)’, the reinforcement for lintels shall consist of mild steel and medium tensile steel bars conforming to IS : 432 (Part I ) 1966 or hard drawn steel wire conforming to IS : 432 (Part II )-1966 or hot rolled deformed bars conforming to IS: 1139-1966 or high strength deformed bars conforming to IS : 1786-1979. Reinforcement shall be free from loose mill scales, loose rust, coats of paints, oil, mud, and any other coating which could reduce the bond between the concrete and the steel. A slight film of rust shall not he regarded as harmful, but the steel shall not he visibly pitted by rust.

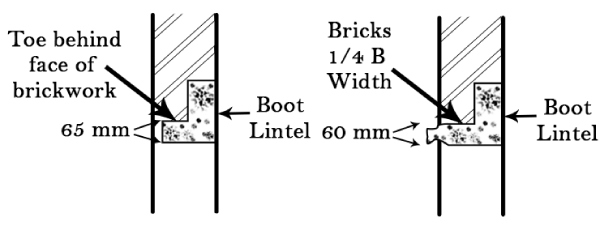

In the case of cavity walls, an RCC boot lintel (L shaped lintel) over the openings may be provided, the details of which are shown above in fig. These are better in appearance as well as economical. But we should always ensure that its toe is strong enough to bear the loads above. A flexible damp-proofing course (D.P.C) should also be provided.

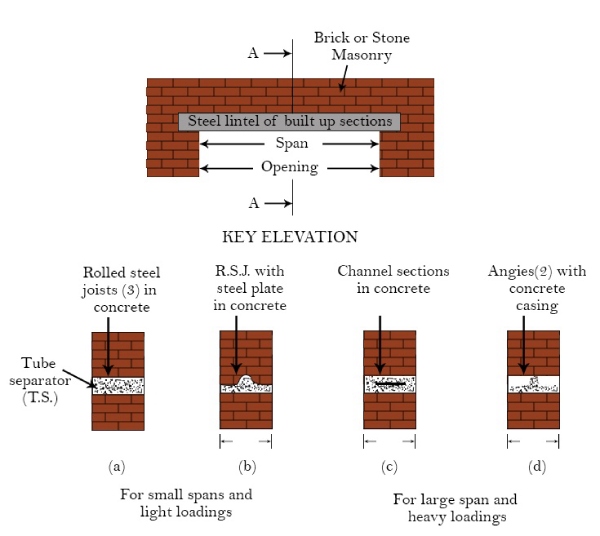

(f) Steel Lintels

These lintels, consisting of rolled steel joists embedded in concrete, are used over large openings, particularly when they have to support a heavy load of solid walls in the position such as shop-fronts, and bay windows. These are sometimes called bressummers. Sometimes, lintels, consisting of steel angles or channel sections in concrete, are used for small spans and light loading, particularly when there is no space above to accommodate an arch or for making a relieving arch. Being very costly, these are restricted for special cases only.

These usually consist of built-up sections of three rolled steel joists or channel sections which are held together at proper distances by tube separators or cross-bolts. The steel built-up sections are embedded in concrete to protect them from the effects of corrosion and fire. Before concreting, a strip of metal lathing or wire netting is placed at the bottom of the steel section to increase the bond or grip between them and the concrete. This whole system is cured like an RCC Lintel.

Types of Lintels

01. Standard Cavity Steel Lintel

This is the most commonly used in construction. The average size range would be around 98 mm consisting of block or brick. They are the leaders in the construction world for their load-bearing ability. They are specially designed to carry the heavy masonry loads. They are known for their strength and stability. Contrary to the belief, they are easy to install and have an attractive galvanized finish too. Another good feature is its durability in the face of thermal changes. Thermal efficiency is an important factor to consider for areas exposed to extreme temperature variations.

02. Wide Inner Leaf Steel Lintels

These types of stones come with the special additional feature of having an inner leaf which can hold the additional blockwork that needs support. These types of lintels are known for supporting blockwork up to a length of around 160 mm They are quite popular in the masonry field. They are available in different lengths with various increments in different size ranges.

03. Wide Outer Leaf Steel Lintels

This type of lintel comes with an outer leaf. The advantage they possess is that they support stone on the outer leaf. Stone is wider than brickwork. Combined lintels can support the extra width which is achieved by using stone. It is very easily installed and can also be detached when not required. This outer leaf is specially designed when the outer stone is used.

04. Short Outer Leaf Steel Lintels

They have an outer leaf with a range of around 75mm and are specially designed to support stonework and not brickwork, unlike its other counterparts. Reconstructed stonework at construction sites is usually supported by this type of lintel. The maximum overall length starts with the size range of 600 mm and in some cases, upwards, offering that much needed extra length. The galvanized finish further enhances the robustness of the end product. These types of lintels are popularly known to support concrete floor loads and point loads, making it extremely valuable in the masonry field.

We have also written article on

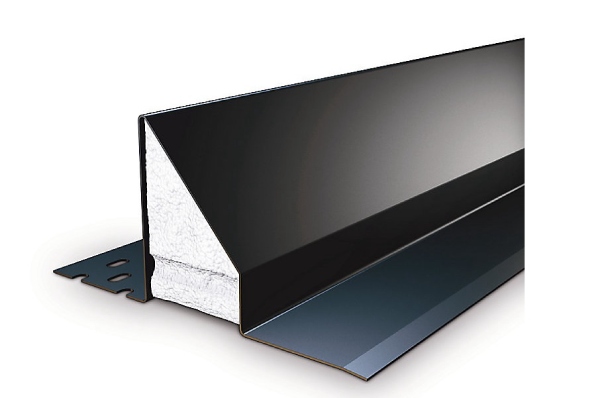

(g) Specialist Lintels – Catnic

Most applications will not need anything other than a concrete lintel or standard steel. However, there are various types of an opening which might require a specialist lintel. These are available in the market as catnic lintel, named after its manufacturing company.

These types of lintels include corrosion-proof coating and thermal insulation so that less heat is lost through these unavoidable breaks in the wall structure. Catnic lintels provide for a wide variety of uses, including under-eave, cavity wall, Corner, timber frame, and heavy-duty or extreme-load lintels.

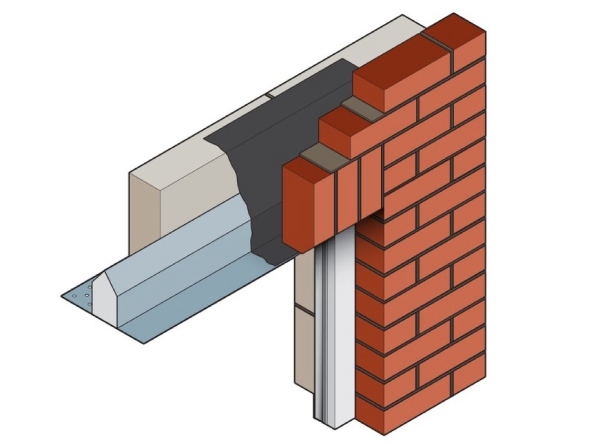

(h) Cavity Lintels

Cavity lintels are designed, as the name indicates, to fit into the cavity of an external wall and can be used to span both door or window openings. The wedge shape helps to carry any water in the cavity to the outside rather than letting it penetrate the inside.

Among all lintels, reinforced concrete lintels are most widely used these days to span the openings. This is because the other materials have become outdated due to many drawbacks. For instance, the wooden ones are prone to decay, the stone ones are costly and may have flaws, and the steel sections are wasteful and become loose when exposed to the sun, and also not free from corrosion.

Remember lintels are a must in the construction world. If you do not provide lintel, you will see upward diagonal cracks in walls, which are difficult to repair later.

Image Courtesy: Image 1, Image 3, Image 4, Image 6, Image 7, Image 8, Image 11, Image 12, Image 13